NB: The below is a brief plain English summary of key points in the report. The Commission's report speaks for itself -- you can download the full document here: www.taic.org.nz/inquiry/mo-2023-205.

Briefly: A cargo ship narrowly avoided grounding after its rudder fell off.

- The TAIC report highlights the need for careful oversight and quality assurance during installation of safety-critical components and for strong international safety standards.

- Key audiences: ship owners and operators, classification societies, insurance providers, shipyards, pilots, ship crews, maritime educators, and flag state regulators.

What happened

On 24 July 2023, the cargo ship Achilles Bulker, fully loaded and under pilotage, was outbound from Tauranga.

The ship deviated from the centre of the channel shortly after clearing the harbour entrance. As the crew and onboard pilots tried to steer it back on course, the ship’s rudder broke off. With steering impossible, the vessel drifted towards shallow water.

Grounding was averted thanks to swift coordinated action by the pilots and crew successfully deploying both anchors,

File photo of bulk carrier Achilles Bulker taken in 2022 near Nelson, New Zealand. The vessel is shown high out of the water, with anchor deployed, positioned behind a low-lying gravel or sandbar. Rust staining is visible along the hull, deck cranes, and superstructure. The ship has four cargo cranes and closed hatch covers, indicating a geared bulk carrier configuration. The vessel is lit by sunlight from a low angle, casting warm tones across the scene. Mountain ranges are visible in the background.

The Achilles Bulker pictured in 2022 near Nelson NZ. Photo (c) Steven Watkins, all rights reserved.

Why it happened

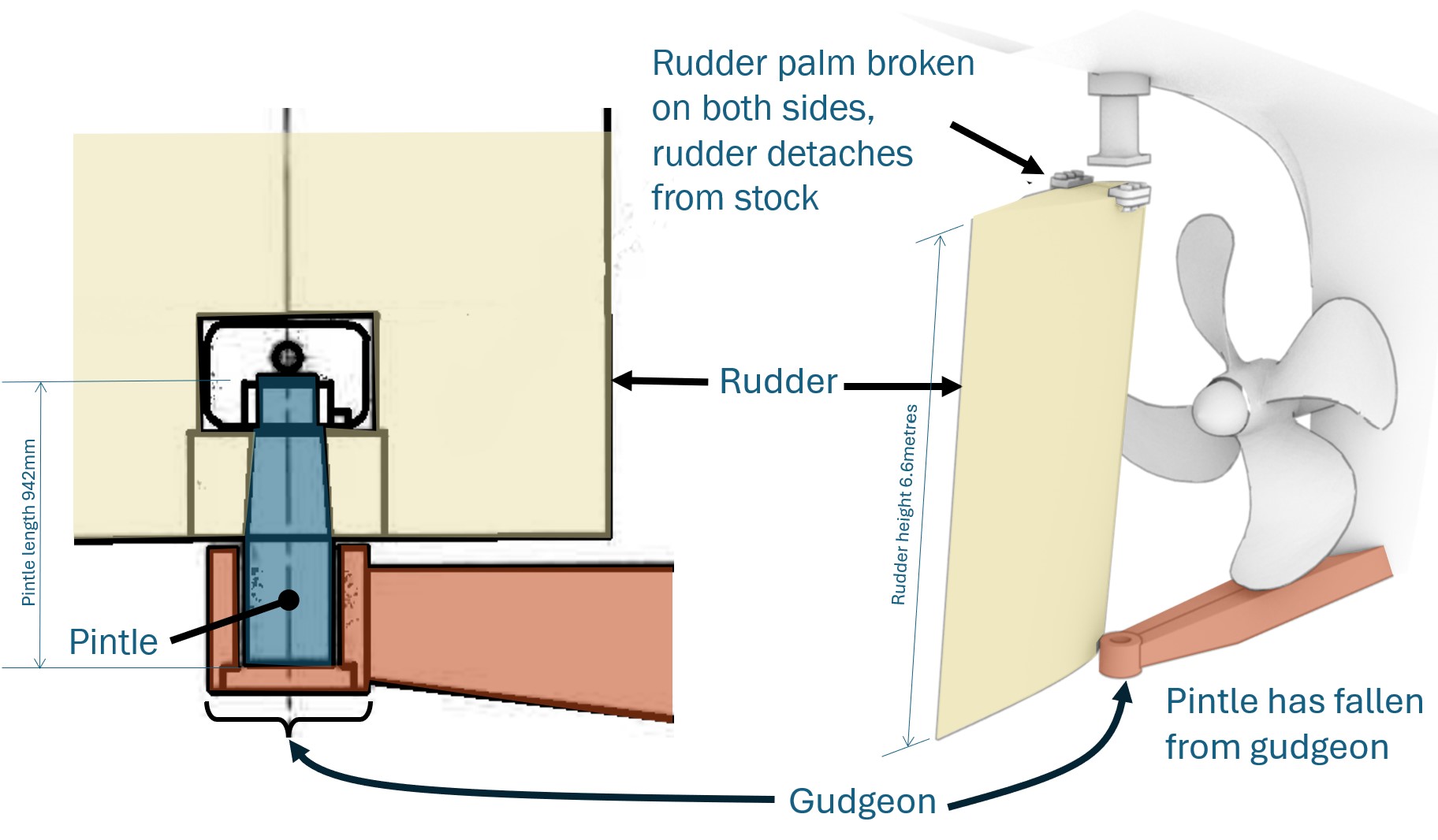

Ineffective maintenance of rudder pintle. Fixed into the base of the rudder assembly was a heavy hinge pin (pintle), which could rotate freely in a matching socket (gudgeon), enabling the rudder to turn. During 2021 dry-dock maintenance, the pintle was removed and refitted, but the securing parts installed had weak, porous welds. After the ship returned to service, those welds broke under vibration.

Pintle dropped out, induced undesigned rudder movement. With its securing parts broken, the nut that retained the pintle as part of the rudder assembly unwound itself. Sometime before the incident off Tauranga, the pintle dropped unnoticed from its casting and sank. Without a pintle, the bottom of the rudder increasingly moved side to side and fore and aft. This exerted sideways forces beyond the designed strength of the coupling plate (palm) at the top that joined the rudder to the solid shaft (stock) that connected to the ship’s internal steering mechanism. Fatigue cracks grew until the rudder fell off.

The rudder palm developed fatigue cracks that grew steadily until the palm fractured completely on both sides of the rudder stock, and the whole rudder blade dropped off.

Figs 4 and 5 from the report show the ship’s rudder main components.

Safety issue and recommendations

The total rudder loss occurred because the rudder system experienced damaging forces, the result of insufficient quality assurance during reinstallation of the pintle. Pintles are critical components of steering systems and must be installed with precise fit and robust quality control.

In principle, owners and operators of ships must maintain oversight of critical system repairs, including during shipyard work.

TAIC recommendations:

- Shipyard QA: That the shipyard that did the dry dock work on this ship implement robust quality assurance procedures for rudder pintle installation. (TAIC has notified the Maritime Safety Administration of China of this recommendation). Rec 043/25.

- International standards: Maritime NZ work with the International Maritime Organisation to promote enhanced global standards for quality assurance of rudder systems during installation, maintenance, and repairs. Rec 044/25.