MNZ has taken further action since recommendation 010/19 was issued, as described below:

Since our response to Draft Report MO-2019-201 in December 2019, MNZ has undertaken a significant overhaul of the system for auditing SOPs under Part 82.

Previously, an MNZ-delegated third party was responsible for compliance activities under Part 82, including:

Inspecting all the vessels requiring an inspection;

Assessing jet boat driver’s license applicants; and

Auditing operator SOPs.

In 2020, the responsibility for auditing operator SOPs was transferred to MNZ staff, with third party delegation limited to vessel inspections and assessing some license applications. The criteria and processes for this limited delegation are still being finalised. Having MNZ staff responsible for auditing all operator SOPs allows for:

Certainty that audits are of high quality; and

Strong oversight of the operators as well as the performance of any delegated third parties.

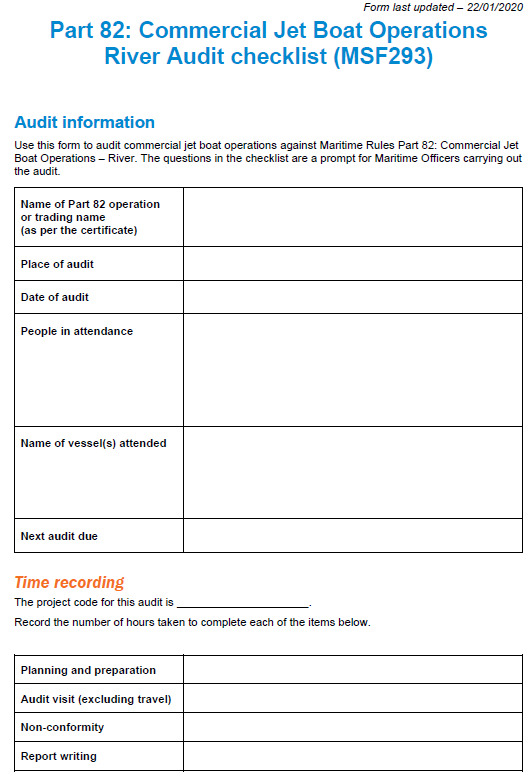

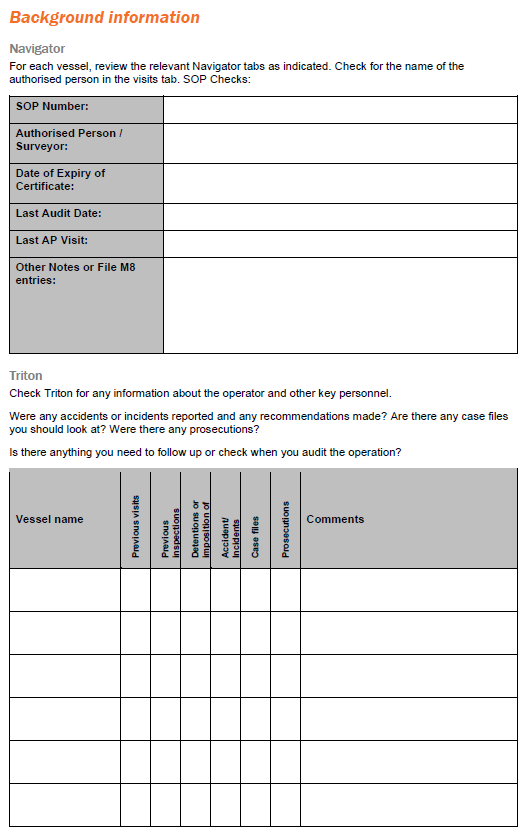

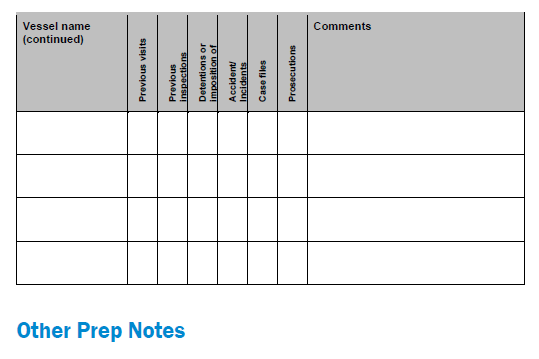

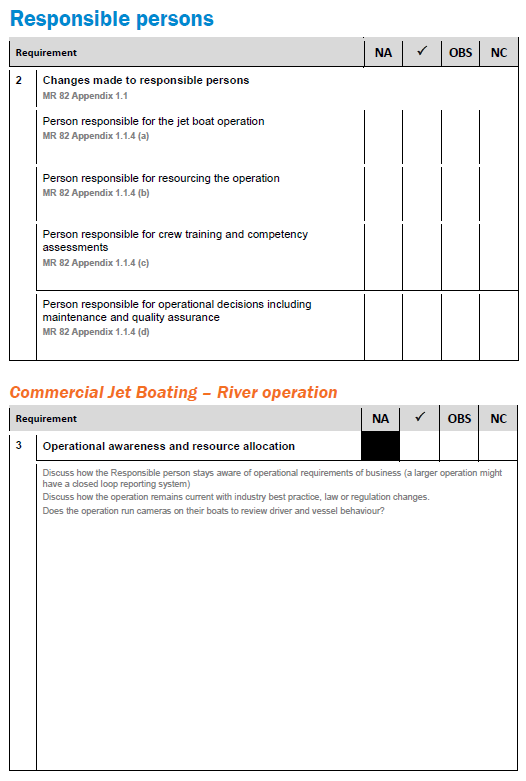

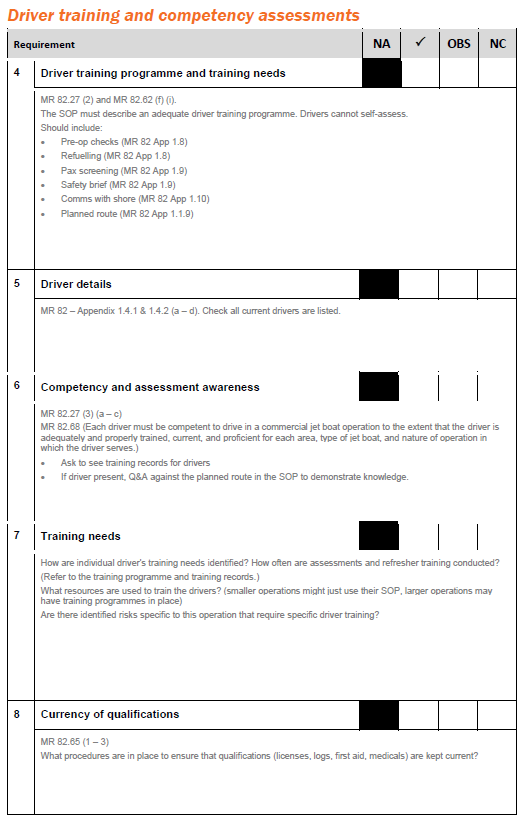

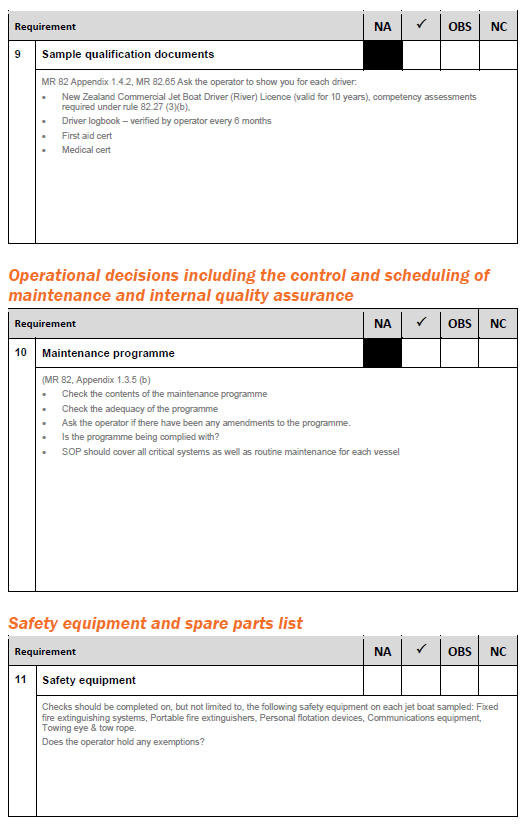

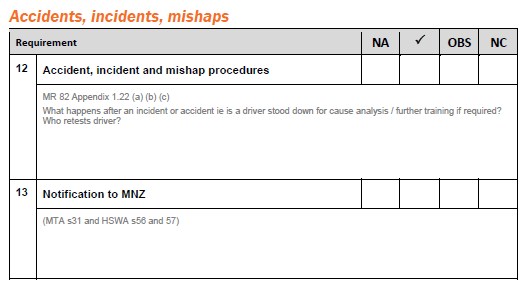

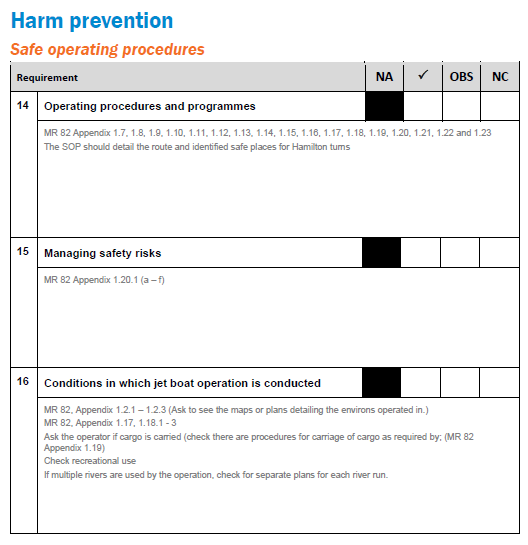

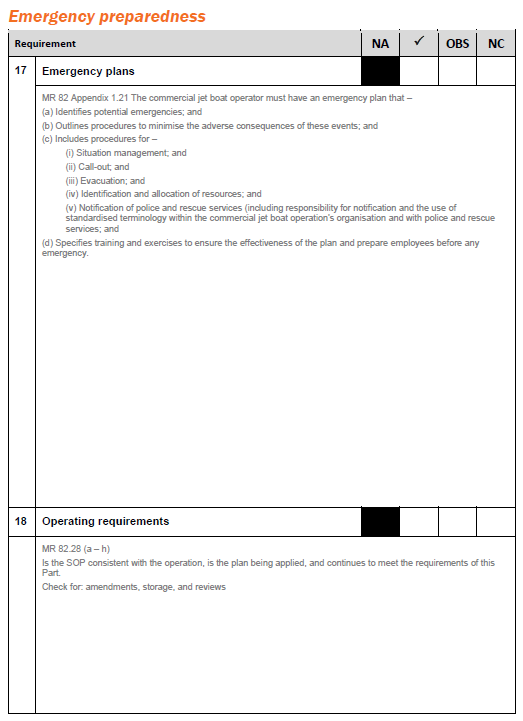

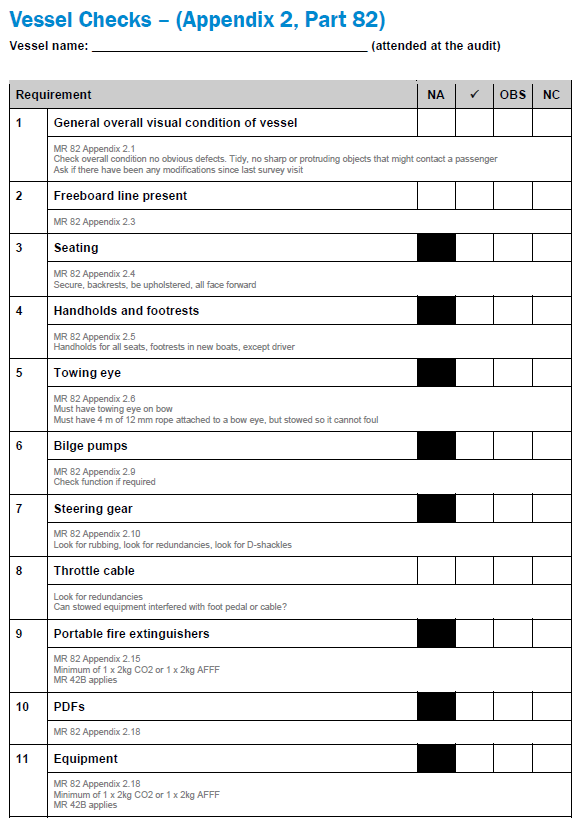

Please see attached our Part 82 Audit Checklist (MSF293). As you can see, audits are in-depth and cover the adequacy of driver competency and maintenance programmes.

For your information, we are also working toward closing TAIC Rec. 010/19, the recommendation that came out of Report MO-2019-201, and hope to be in a position to do that soon.