A trainee rail protection officer authorised workers to start work on the main south line in Hornby before a scheduled train had passed through. The workers realized a train was approaching when level crossing bells started ringing and were able to get off the track in time. TAIC identified failings in supervision and in training RPOs to supervise trainees. Further, available engineering controls (which physically reduce hazards) were not being used.

Executive summary Tuhinga whakarāpopoto

What happened

- On 7 March 2024, Fulton Hogan Limited (Fulton Hogan) was undertaking construction work within the rail corridor on the Main South Line, between the intersections of Halswell Junction Road and Parker Street at Hornby, Christchurch.

- The protection arrangement for track workers accessing the rail corridor was compulsory-stop protection managed by Fulton Hogan’s trainee Rail Protection Officer (RPO) and a supervising RPO.

- While working under the compulsory-stop protection, the trainee RPO authorised two trains to pass through the worksite while track workers were clear of the track.

- After the first train had cleared the worksite, the trainee RPO authorised the track workers to access the track to commence work before the second train had passed through the worksite.

- At about 0900 (times in this report are in New Zealand Daylight Time (Universal Coordinated Time +13 hours) expressed in a 24-hour format) the level-crossing protection alarms at Halswell Junction Road and Parker Street activated, with bells ringing. The track workers realised that a train was approaching the worksite and left the track for the safe place. No one was injured.

What we can learn

- Providing adequate training for supervisors is necessary to ensure that there is a clear understanding of what adequate supervision means and its importance in maintaining safety, particularly where supervision relates to mentoring and coaching trainees conducting safety-critical tasks.

Who may benefit

- The lessons from this incident will benefit all industries where the supervision of safety-critical tasks performed by inexperienced or unqualified staff is necessary to maintain safety.

Factual information Pārongo pono

Background

- Between January and March 2024, KiwiRail Holdings Limited (KiwiRail) contracted Fulton Hogan Limited (Fulton Hogan) to install pits and conduits for data cabling within the rail corridor. The location of the work was on the Main South Line (MSL) between Rolleston and Hornby. Fulton Hogan had subcontracted some of the work to K Drainage Limited.

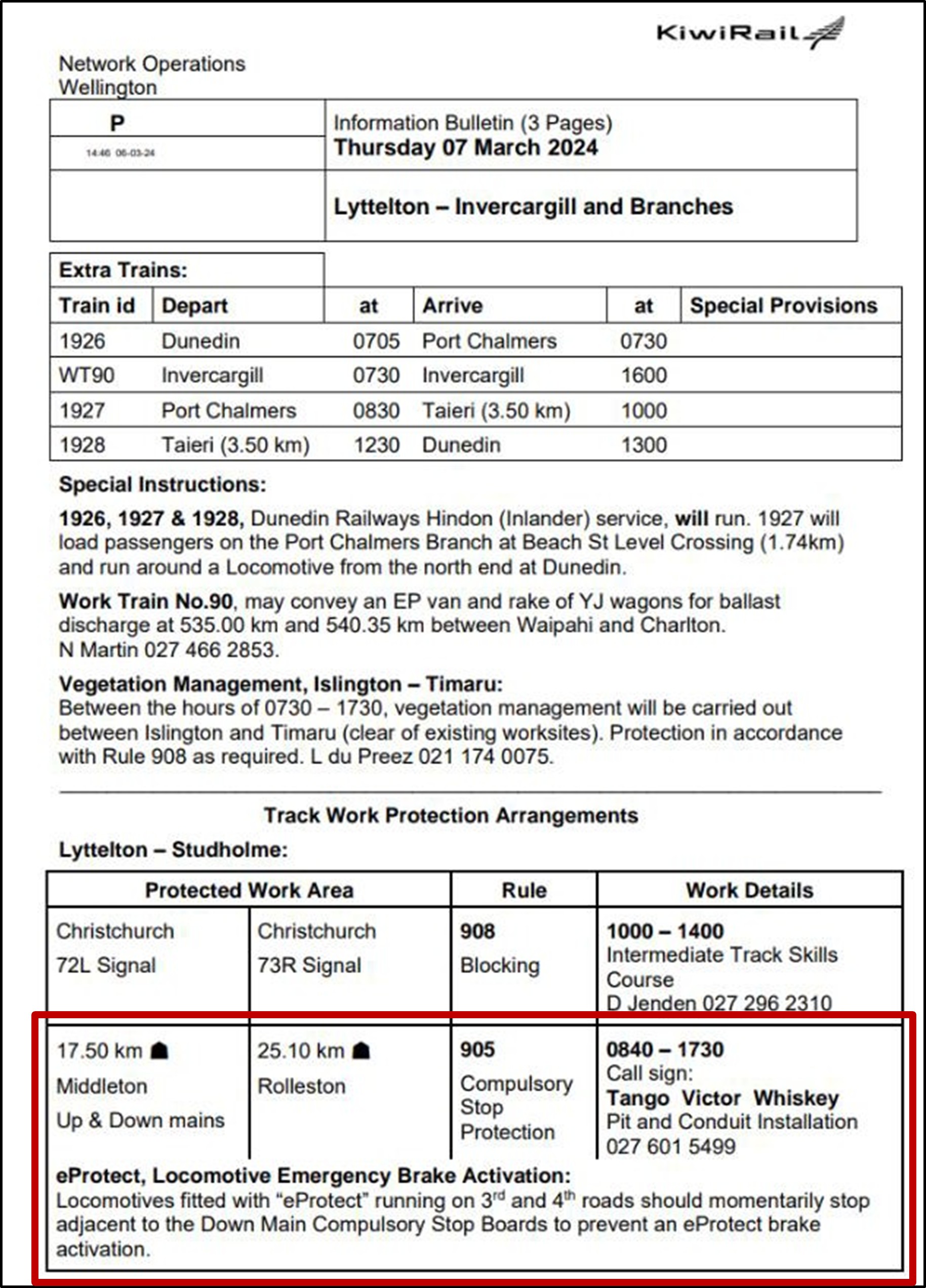

- KiwiRail provided information on the planned work, including the protection arrangements, in its Daily Information Bulletin (DIB).

- The DIB was used to inform:

- train controllers about the locations of planned work and the intended protection methods for and timings of the work on tracks

- the rail protection officers (RPOs) about the work protection systems that were authorised, and where the protections were to be placed

- the locomotive engineers operating in the locality about the protection arrangements, so they could plan their train handling accordingly.

- Fulton Hogan was to conduct the planned work under KiwiRail’s rail licence, approved safety case and safety system, as it was not required to be licensed under the Railways Act 2005 (the Act).

- KiwiRail was required to take all reasonable steps (including providing necessary monitoring personnel and resources) to ensure that Fulton Hogan carried out the works in accordance with KiwiRail’s licence, the approved safety case, the safety system and any relevant rules as required by section 22 of the Act. Fulton Hogan was using its own RPOs to oversee the protection of track workers and equipment accessing the track.

Narrative

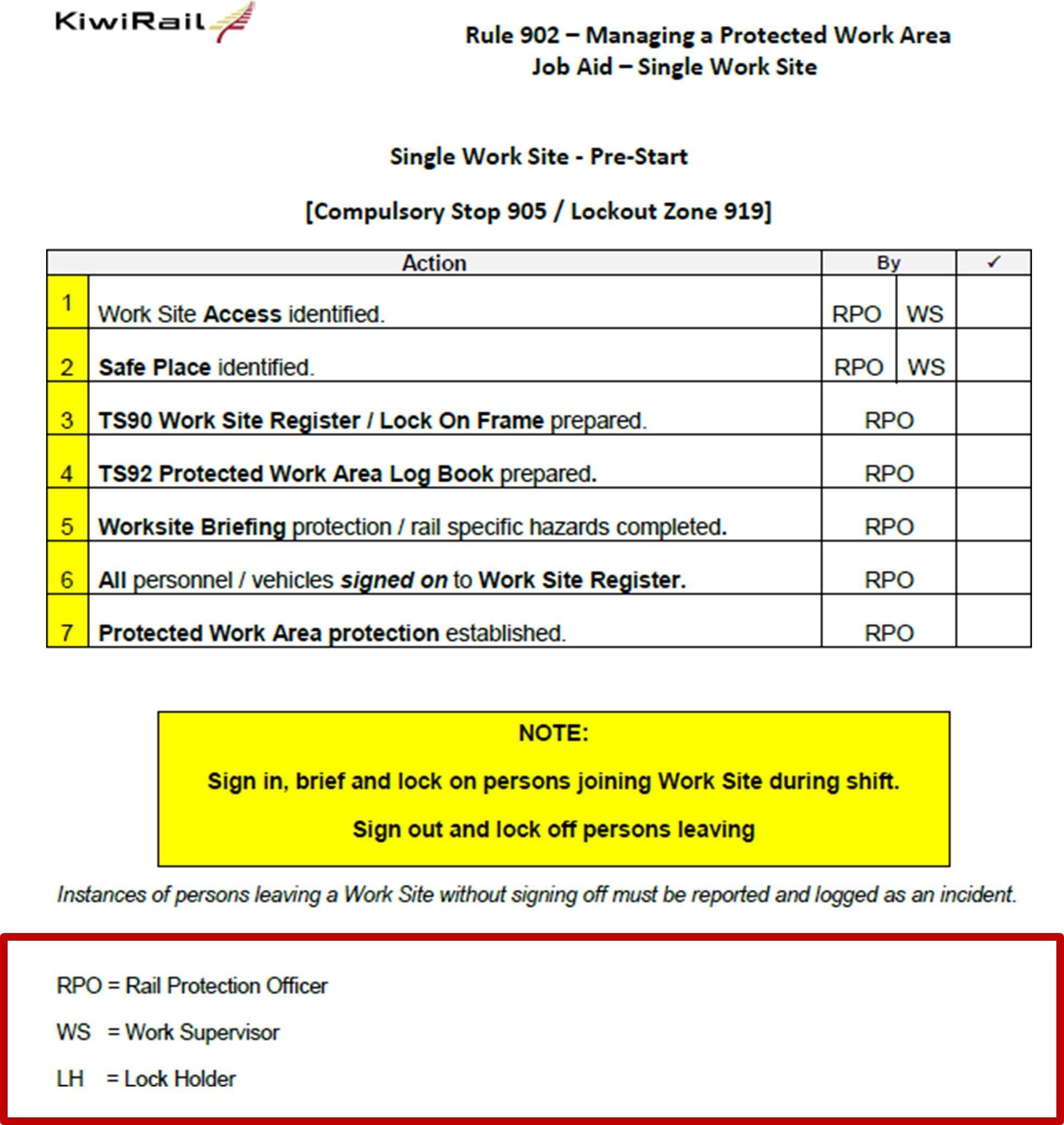

- On 7 March 2024, a trainee RPO and supervising RPO employed by Fulton Hogan started work on preparing the protection arrangements for the Protected Work Area (PWA) listed in the DIB dated 7 March 2024 (see Appendix 1).

-

The protection arrangements were scheduled to start at 0840 using compulsory-stop protection. This method of protection was prescribed in KiwiRail’s Track Safety Rules (Rule 905, Track Safety Rules, 6 November 2021) as an authorised method of protection and required the placement of signage boards at each approach to the worksite. The arrangement of the boards followed a defined sequence and minimum distance from the worksite (see Figure 3).

Figure 3: Compulsory-stop protection board placements (Source: KiwiRail Rules and Procedures – Track Safety Rule 905) - The description of the boards, together with the meaning of each sign was contained in KiwiRail’s Track Safety Rule 905(c) (see Figure 4)

- The location of the intended work area (a single worksite) was at Hornby, between the level crossings at Halswell Junction Road (21.27 km) (track kilometre (km) defines the location from a reference point. On the MSL the reference point is Lyttleton, which is at 0 km, and ends in Invercargill at 601.40 km) and Parker Street (20.69 km) (see Figure 5).

- The specified PWA required the placement of the boards at Middleton (17.50 km) and Rolleston (25.10 km) on the MSL. The supervising RPO and trainee RPO planned to travel to these locations separately, with the trainee RPO tasked with placing the boards at the Middleton end and the supervising RPO taking the Rolleston end of the PWA.

- Before the placement of the protection boards, two train services were scheduled to pass through the location where the PWA was to be established. The first of these was the TranzAlpine passenger service, Train 803, heading towards Rolleston. This was to be followed by a freight train service, Train 882, heading towards Middleton.

- The TranzAlpine service cleared the location by 0820 as scheduled, but Train 882 was delayed. The service was not expected to pass through the worksite before 0840, at which time the PWA would need to be established in accordance with the DIB.

- The DIB specified that the PWA was to be in place from 0840 to 1730 and that the worksite location was to use the E-Protect system. The use of this system meant that even without the placement of the compulsory-stop boards, the E-Protect would be active.

- At 0830 the trainee RPO and the supervising RPO had placed the required boards at both ends of the PWA. The trainee RPO contacted train control by radio to report that the stop protection was in place at both approaches to the PWA

- The Transport Accident Investigation Commission (the Commission) obtained the recorded voice logs from KiwiRail’s Train Control System and determined that train control had acknowledged the call and advised the trainee RPO that two services were expected through the location that morning. These were the delayed Train 882 and a shunt from Middleton (train control used the term ‘shunt from Middleton’ in reference to Train 973). Train control further advised the trainee RPO that the trains were due around 0815, before correcting their transmission and providing a time of 0945.

- With the compulsory-stop protection in place, the trainee RPO made their way back to the designated safe place located on the south side of Waterloo Road (see Figure 6). The track workers and machinery, which included an excavator and a hydrovac truck, were already at the location. The trainee RPO advised the track workers that the track could not be accessed until Train 882 had cleared the worksite.

- The trainee RPO was experiencing interference on the radio, which they attributed to the overhead power lines. They relocated their vehicle to the north side of the road to maintain clear radio communication with train control and any approaching trains that needed authorisation through the worksite.

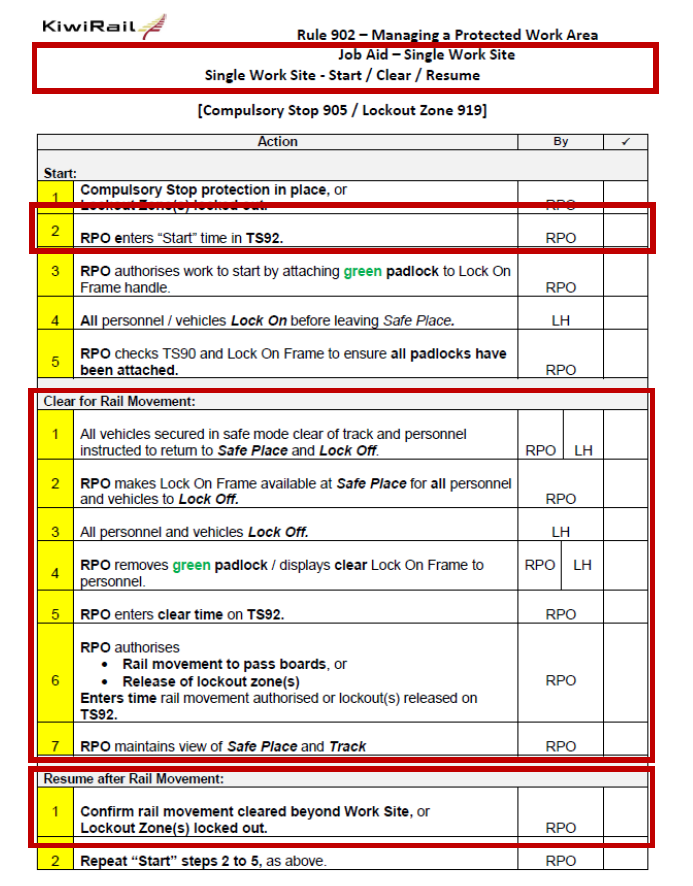

- While waiting for the arrival of Train 882, the trainee RPO pre-empted the train movement by entering ‘882’ into the first column of ‘Rail Movement (the operation on rail of rail traffic) ID’ in the TS92 Single Work Site – Protected Work Area Logbook (a document to be completed when undertaking protection duties using stop protection) (TS92 logbook) (see Figure 7).

- At 0846 Train 973 arrived at the Middleton end of the PWA. The locomotive engineer stopped Train 973 and contacted the trainee RPO for permission to enter and pass through the worksite.

- The trainee RPO was surprised by the call as they had not expected a train movement at that time. They altered the TS92 logbook by placing a line through the number ‘882’ and replacing it with ‘973’, then writing ‘882’ in the next column along.

- At 0847 the trainee RPO authorised the locomotive engineer of Train 973 to enter the PWA and travel through the worksite, proceeding at the normal track speed. The trainee RPO wrote this into the TS92 logbook.

- The trainee RPO then directed their attention to locating Train 882 using the GeVis application on a mobile device. The train was between Rolleston and Templeton and had not yet arrived at the stop board.

- At 0851 Train 882 stopped at the Rolleston end of the PWA. The locomotive engineer contacted the trainee RPO for permission to enter the worksite. At 0852 the trainee RPO authorised the locomotive engineer of Train 882 to enter the PWA and travel through the worksite, writing this in the TS92 logbook.

- With the communications complete and both Train 973 and Train 882 authorised to enter the worksite, the trainee RPO moved their vehicle back across the road to the designated safe place.

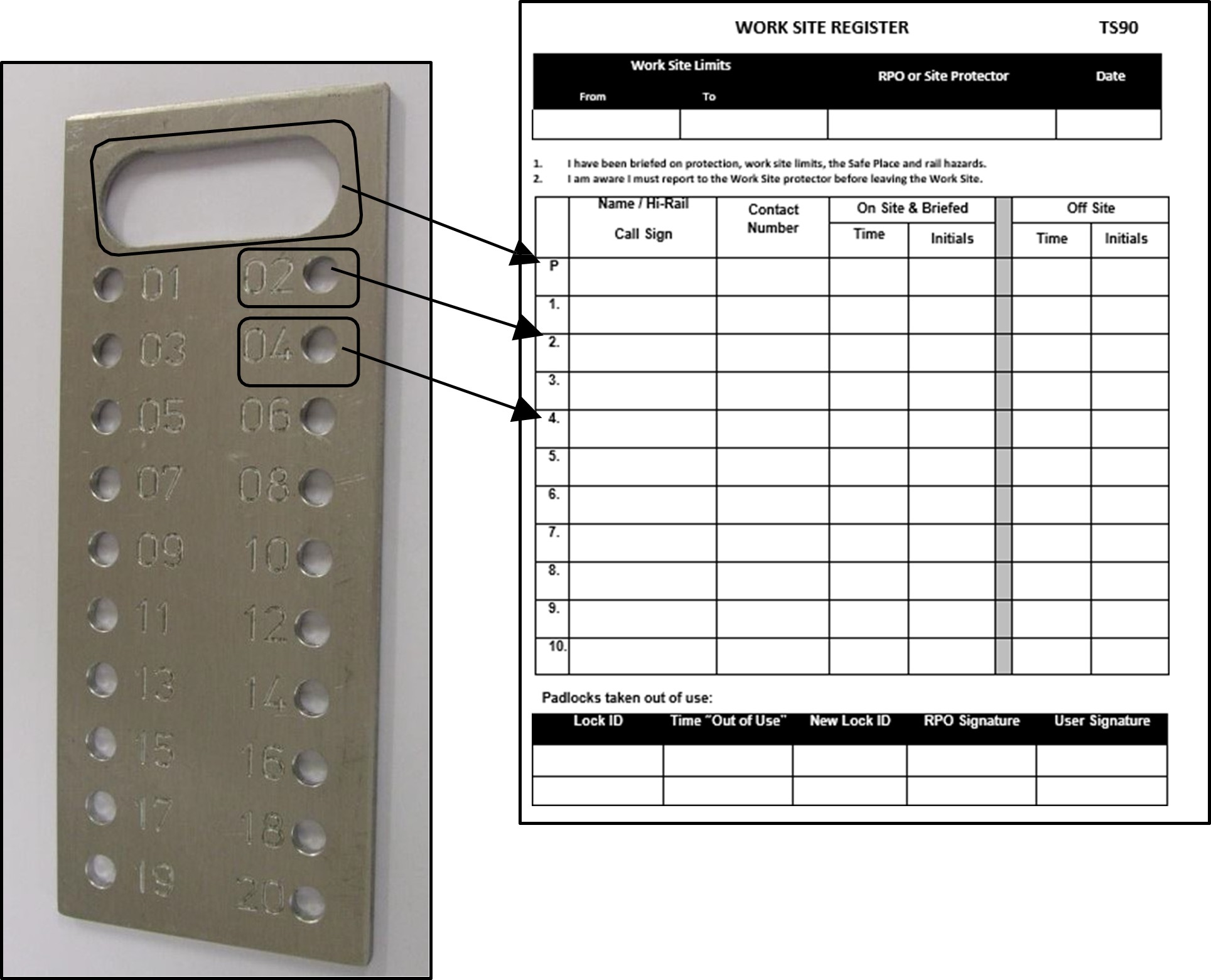

- The trainee RPO began filling in the Fulton Hogan risk control plan form (documentation relating to Fulton Hogan’s internal processes of documenting and managing risks on a worksite, incidental to the RPO duties) while the track workers completed their respective entries into the TS90 Work Site Register (see Figure 8). At about that time Train 973 passed the worksite and the safe place, where the trainee RPO and track workers were located, as it headed towards Rolleston.

- Train 882 had also entered the PWA but had not yet arrived at the worksite. The trainee RPO placed their green padlock onto the lock-on frame and commenced the process of aut horising the track workers to enter the rail corridor. This involved the trainee RPO presenting the lock-on frame to the track workers, so that each track worker could place their personal lock onto the frame (see Figure 9).

- The four track workers then placed their respective padlocks on to their designated numbers located on the lock-on frame. These numbers coincided with the numbers on the TS90 Work Site Register, where the workers had previously signed and provided their particulars (see Figure 8).

- The track workers who had locked their padlocks onto the lock-on frame left the safe place and entered the rail corridor to commence work. Their designated tasks included placing conduit piping alongside the rail tracks in preparation for the excavation work. One of the track workers, a designated mobile-plant controller, made their way to the excavator that was parked clear of the track.

- At about 0900, the track workers and the trainee RPO heard the level-crossing alarms at Halswell Junction Road and Parker Street, indicating an approaching train. They responded by immediately clearing the rail corridor and returning to the safe place.

- It was at this time that the trainee RPO realised they had not accounted for Train 882 before locking on the track workers and authorising them to enter the rail corridor.

- At 09:01:09 Train 882 crossed Halswell Junction Road level crossing and entered the worksite. The track workers had all cleared the track before the train passed through, but their padlocks and the trainee RPO’s padlock were still attached to the lock-on frame.

- At about the same time, the supervising RPO, who had been absent from the safe place, returned and noticed that the lock-on frame still had the padlocks attached when the train passed through the worksite. They identified that there had been a significant departure from the correct process.

- The supervising RPO took control of the site and protection duties, the communications with train control, the TS90 Work Site Register, the TS92 logbook and the lock-on frame. The trainee RPO contacted Fulton Hogan management and reported the incident, and the matter was later reported to KiwiRail. The worksite was subsequently closed for the remainder of the day. There were no injuries to any of the track workers.

Personnel information

- The trainee RPO was employed by Fulton Hogan and was undergoing training for qualification as an RPO. Trainees are not ‘licensed to operate’ until they are fully qualified. The qualification is obtained through an assessment process conducted by the KiwiRail Operational Safety Advisor. Assessments can only be undertaken once the theory-based training and all practical ‘On-the-Job Training’ (OJT) tasks have been completed by the trainees. Once qualified, RPOs are authorised to operate on KiwiRail networks and are subject to routine safety observations and revalidations.

- The trainee RPO had completed the theory-based training between July and September 2023 and had fulfilled two of the ten competencies gained through OJT. At the time of the incident they were receiving OJT for stop-protection duties.

- The supervising RPO was employed by Fulton Hogan. They had about 15 years’ experience in rail-protection duties in New Zealand and overseas. They were qualified for the protection duties being undertaken at the time.

- The supervising RPO had some previous experience in training other personnel in rail-protection duties. However, they had not received any additional or formative training for their role as a supervisor of trainee RPOs and had not completed the Coaching for Competency training course in KiwiRail’s training system.

Train/Vehicle information

- Train 882 was a freight train consisting of a DXB-class diesel electric locomotive as the lead locomotive. The train length was 316 metres (m), and it had a gross weight of 460 tonnes (t).

- Train 973 was a light engine (locomotive only) operation consisting of a DCP-class diesel electric locomotive.

Recorded data

- The locomotives of Train 882 and Train 973 were both fitted with Tranzlog data recorders. The information from the recorders was obtained by the Commission to inform the investigation.

- The Tranzlog recorder showed the trains’ positions and speeds along the route as well as the drivers’ inputs and the timing of voice calls.

Worksite information

- The worksite location consisted of a duplicated track with UP and DOWN directions (trains running towards Lyttleton on the MSL in the South Island are UP trains and those running towards Invercargill are DOWN trains. UP trains have even numbers and DOWN trains have odd numbers) (see Figure 10).

- The track immediately before the worksite entry has a curve with a 1000 m radius, curving to the right when viewed from the direction of Halswell Junction Road towards the worksite location. The track geometry and surrounding environment provide limited visibility for sighting approaching trains.

- The method of controlling train movements is automatic signalling, which uses coloured light signals controlled by a train controller based in the Wellington Train Control Centre.

- Parker Street and Halswell Junction Road both had level crossings protected by half-arm barriers, flashing lights and audible alarm systems that were operating at the time of this occurrence.

- The normal track speed for freight trains at this location is 80 kilometres per hour (km/h). There was a temporary speed restriction of 40 km/h on the line at the time of the incident, which was unrelated to the work being undertaken.

Organisational information

KiwiRail Holdings Limited

- KiwiRail Holdings Limited (KiwiRail) is a New Zealand state-owned enterprise. It operates trains and rail vehicles, controls rail movements on the national rail network, and maintains the railway infrastructure.

- KiwiRail is a rail operator and the rail access provider and therefore requires a licence under the Act.

Fulton Hogan Limited

- Fulton Hogan provides rail and civil construction services, including the inner-city, suburban and regional rail projects.

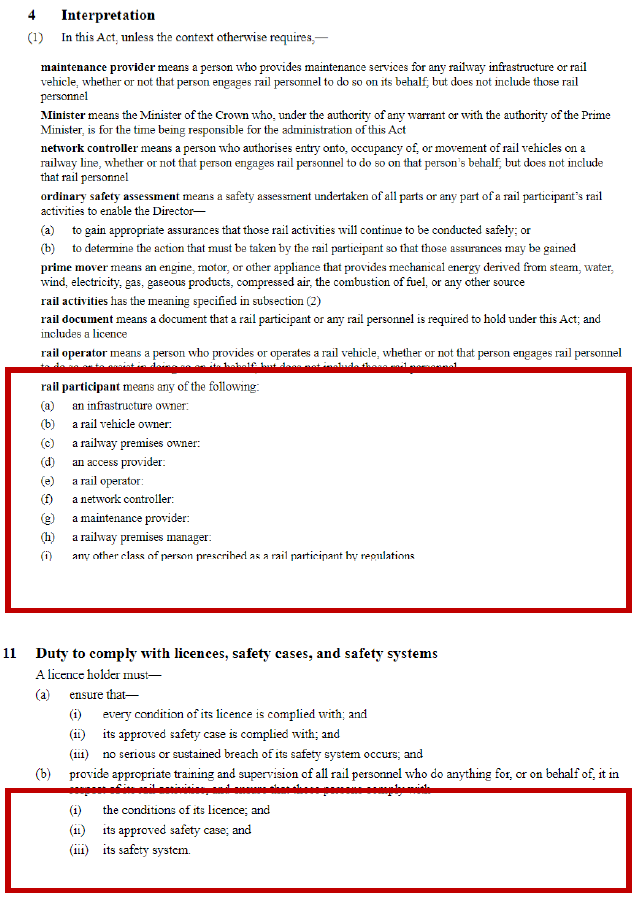

- Fulton Hogan is a rail participant (Section 4 of the Railways Act 2005 defines a rail participant, which includes a maintenance provider (see Appendix 4)) under the Act, but for the purposes of this work it was not required to be a rail license holder. The track workers and RPOs employed by Fulton Hogan and its subcontractors were rail personnel under the Act.

Previous occurrences

Rail Inquiry RO-2014-104

- In 2014 a train collided with an excavator on the North Island Main Trunk Line (Transport Accident Investigation Commission, December 2016). A track maintenance work area had been established between National Park and Raurimu on the North Island Main Trunk and an RPO was in charge of the site’s safety. Two trains were scheduled to pass through the area. The first train passed through without incident and the RPO authorised the second train to pass through the area. However, an excavator driver had driven onto the track to start work.

- The train had passed the main work group and rounded a curve in the track when the train driver saw the excavator on the track ahead. Despite an emergency brake application, the train could not be stopped before it collided with the excavator. Non-compliance with KiwiRail’s standard operating procedures for the planning, establishment and running of the PWA was a factor that contributed to the accident.

- The inquiry into this occurrence identified a key lesson: track workers with safety-critical roles can be placed in unsafe situations when standard operating procedures are not followed. This inquiry prompted the introduction of KiwiRail’s Track Safety Rule 902 – Managing a protected work area, and the lock-on procedures designed to ensure that track workers are clear of tracks before rail movements are authorised to enter worksites.

Rail Inquiry RO-2019-101

- In 2019, an RPO conducting protection duties in Westfield, Auckland allowed a signals technician into a work area without the knowledge of train control. Subsequently, electronic protection was removed by train control while a signals technician was still conducting work (Transport Accident Investigation Commission, May 2020).

- The key lesson from this investigation was that all personnel undertaking safety-critical roles should adhere to the principles underlying the application of non-technical skills to ensure that they share the same mental models and have a clear understanding of what is required of themselves and others to complete a task safely.

Rail Inquiry RO-2020-104

- In 2020 a freight train on the East Coast Main Trunk line entered a section of track that the RPO believed was part of a PWA and that was already occupied by a contractor operating a hi-rail vehicle. A collision between the train and the hi-rail vehicle was only avoided because the driver of the hi-rail vehicle had voluntarily cleared the track about five minutes earlier (Transport Accident Investigation Commission, January 2022).

- This investigation identified that KiwiRail had recorded 61 track-occupancy irregularities between June 2019 and May 2021. Of these 61 incidents, 21 were attributable to miscommunication.

- The Commission recommended that KiwiRail carry out an analysis of how it could best incorporate engineering control measures into both its current and future operations to minimise the risks of human factors in the effective protection of track workers (see Rail inquiry RO-2020-104 recommendation 009/21).

Rail Inquiry RO-2023-103

- In 2023, the driver of a Transdev passenger train reported to train control an unexpected sighting of track workers. The track workers had arrived at the northern entrance to a tunnel without the required permission and without any protection from rail traffic (Transport Accident Investigation Commission, March 2024).

- Train control had recorded the intended track occupation by the track workers on the train control diagram at locations different from those requested by the track workers, and applied electronic-blocking protection at those incorrect locations. The track workers did not identify the location discrepancies while listening to train control stating the protection details and repeated back the incorrect locations without challenge.

- The key lesson from this investigation was that all personnel undertaking safety-critical roles should adhere to the principles underlying the application of non-technical skills to ensure that they share the same mental models and have a clear understanding of what is required of themselves and others to complete tasks safely.

ATSB Rail Investigation RI-2014-011

- The Australian Transport Safety Bureau (ATSB) has investigated several accidents and incidents involving maintenance work being performed on or near railway tracks. The ATSB SafetyWatch, introduced in 2012 to emphasise broad transport safety concerns in Australia, also highlighted ‘safe work on rail’. (Australian Transport Safety Bureau, 2017)

- The ATSB commented that incidents were predominantly a result of errors during the implementation or dissolution stages of providing track protection. Either protections were removed incorrectly or prematurely, or key communication exchanges failed to establish the location of the worksite with respect to approaching rail traffic.

Analysis Tātaritanga

Introduction

- The following section analyses the circumstances surrounding the event to identify those factors that increased the likelihood of the event occurring or increased the severity of its outcome. It also examines any safety issues that have the potential to adversely affect future operations.

- The safe separation and protection of track workers from rail vehicles is a fundamental premise of any rail operation. It is therefore essential that robust and proven safe methods of working are in place to prevent potential interactions between track workers and rail traffic.

- On this occasion the trainee RPO allowed personnel to enter the rail corridor without following the correct procedure. As a result, a significant safety barrier was breached.

- The following analysis discusses the event and the circumstances surrounding the entry of rail traffic into a PWA while track workers were still present and working on the track.

Track-protection processes

- The PWA was being managed by a trainee RPO under the supervision of an RPO. The purpose of the PWA was to ensure that all personnel within the worksite were protected from rail movements.

- The rules required protection to be applied when work was to be carried out or had the potential to be carried out within 4 m of the centre line of the closest railway line.

- The PWA is the defined section of line or lines where track workers are carrying out activities using approved protection methods. The protection method applied was KiwiRail’s Track Safety Rule 905 – Compulsory-Stop Protection.

- The protection method had been properly applied at this location and it was working as intended, with both Train 973 and Train 882 stopping at the respective compulsory-stop boards and obtaining permission to enter the PWA.

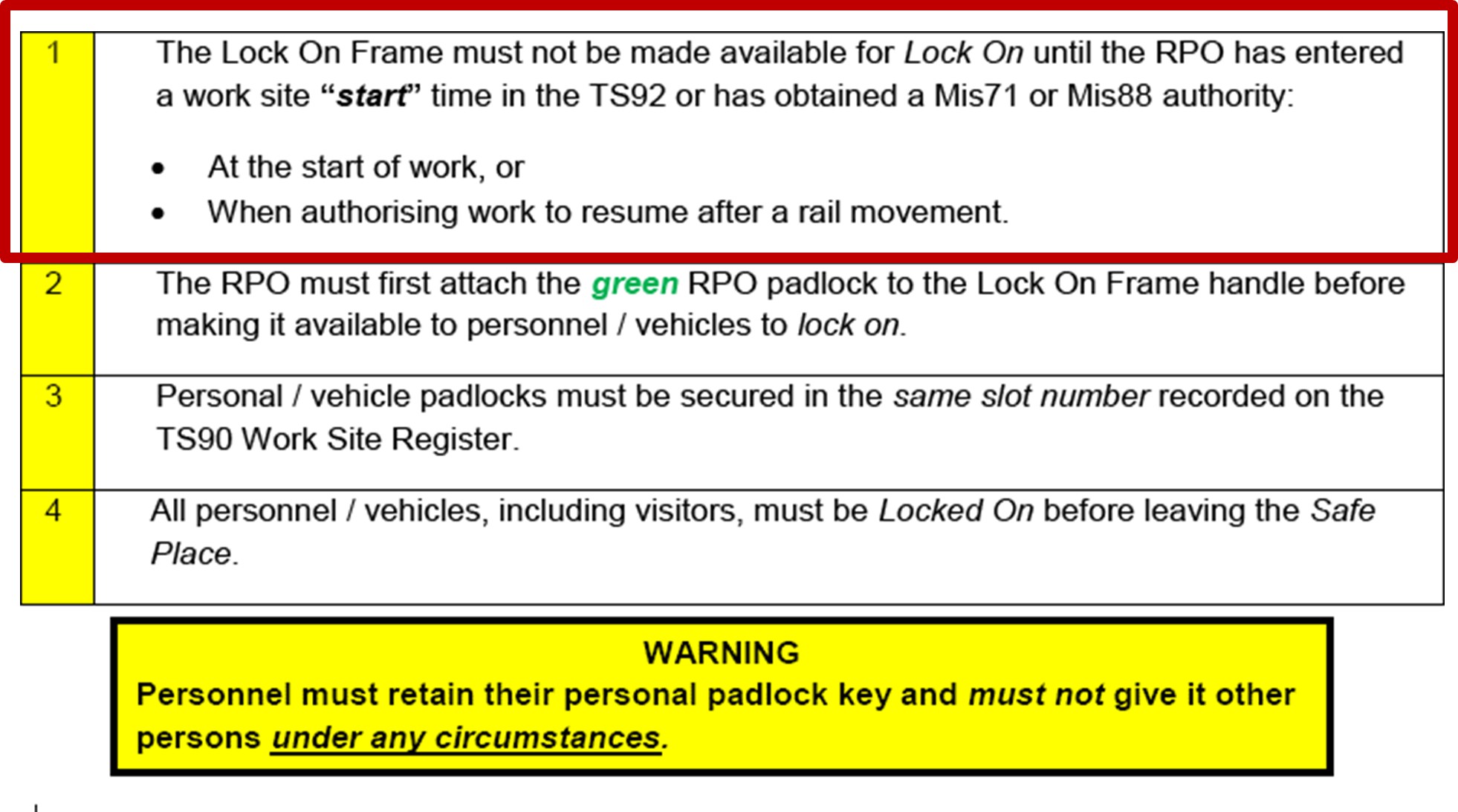

- Additional systems were in place with the application of KiwiRail’s Track Safety Rule 902 – Managing a protected work area. The purpose of this rule was to ensure that all personnel and equipment on a worksite were accounted for when starting work on track and when completing and clearing the track before the PWA was released back to rail traffic.

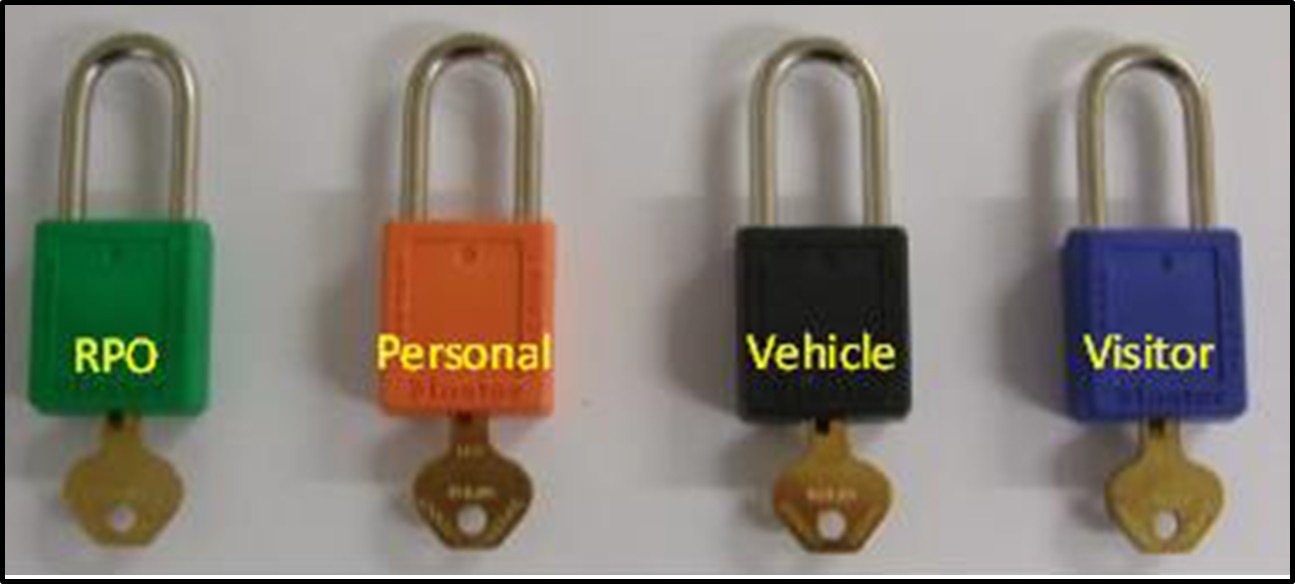

- The rule required each track worker to have a padlock that they locked onto a frame when on track and removed when clear of the track at the designated safe place. The process also accounted for vehicles on track or positioned clear of the track at a designated area as appropriate, with their padlocks removed from the lock-on frames.

- Each of the padlocks was personal to the owner or the vehicle, and colour coded according to the role of the padlock (see Appendix 2).

- The compulsory-stop protection, and the lock-on process were recorded on the TS90 Work Site Register and in the TS92 logbook. These protections were administrative controls and the process had to be followed meticulously to be effective.

- The trainee RPO had entered into the TS92 both the train details and the time that each train was given authority to pass the compulsory-stop boards. However, following the passage of Train 973 past the worksite, the presentation of the lock-on frame to the track workers without entering the worksite start time on the TS92 logbook was contrary to the guidance provided in KiwiRail’s Track Safety Rule 902 Managing a Protected Work Area Job Aid (see Appendix 3).

- This procedural error meant that the opportunity to recall the next step in the process of waiting for Train 882 to pass was missed. Had the trainee RPO taken the step to record that detail in the TS92 logbook, it is likely that they would have recalled that Train 882 had yet to pass the worksite and would not have proceeded to the next step of presenting the lock-on frame to the track workers.

- Stop protection on duplicated tracks and two trains approaching from opposite directions require high levels of proficiency. The trainee RPO was carrying out these tasks unsupervised and with limited experience.

- In interview, the trainee RPO recalled that at the time they ‘had lost [their] place and there was too much going on’. It is at these times that trainees need the support and close supervision of experienced and competent trainers/mentors.

- Had the supervising RPO been present to provide guidance and intervention when the trainee RPO authorised the track workers to access the worksite while Train 882 was approaching, it is likely that the error would have been detected and appropriate action/s taken to prevent the near miss incident.

KiwiRail obligations as rail licence holder

Safety issue 1: KiwiRail, as the rail licence holder (A person who (or organisation that) is required to hold a licence under Section 15 and has been granted a licence under Section 17 of the Railways Act 2005), did not take all reasonable steps to ensure that Fulton Hogan carried out track-worker protection in accordance with KiwiRail’s safety case and safety system. KiwiRail’s RPO training, provided to Fulton Hogan RPOs, did not describe the level or purpose of supervision of a trainee RPO.

Obligations of rail participants under the Railways Act 2005

- The Act establishes a duty of rail participants and persons working for rail participants to ensure the health and safety of persons so far as is reasonably practicable (Section 7, Railways Act 2005). The Act further requires certain rail participants to be licensed (Section 10, Railways Act 2005). Operators and rail access providers that are required to be licensed need to develop safety cases, which must be submitted to and approved by the Rail Regulator, New Zealand Transport Agency Waka Kotahi, as a prerequisite to the issuing of a licence.

-

Section 30 of the Act specifies, among other requirements, that a safety case must contain a statement or description, as appropriate, of the following:

(g) the arrangements in place to ensure that —

…

(ii) safety-critical tasks and activities are clearly identified; and

(iii) rail personnel carrying out safety-critical tasks and activities have received appropriate training and instruction; and

(iv) the competence of rail personnel carrying out safety-critical tasks and activities has been appropriately tested.

…

-

Section 22 of the Act imposes a licence condition on licensed rail operators and rail access providers that:

…

if the rail activities are carried out by another person who does not hold a licence, the licence holder must take all reasonable steps (including providing necessary monitoring personnel and resources) to ensure that the person carries out those rail activities in accordance with the licence, the approved safety case and safety system and any relevant rules.

…

-

These sections of the Act require KiwiRail to provide appropriate training, supervision and testing of all personnel who conduct safety-critical tasks within its rail operation, including contractors and their subcontractors.

Fulton Hogan as contractor

- Fulton Hogan was contracted by KiwiRail to undertake work within the rail corridor associated with the maintenance of the infrastructure.

- Fulton Hogan had a ‘Permit to Enter’ (the necessary authority required for working in, or impacting on, KiwiRail rail operational areas, unless working under direct KiwiRail supervision) the rail corridor for the purpose of the work being undertaken. KiwiRail required a permit at any time that authority to enter the rail corridor was needed. The conditions of entry included a requirement for rail protection to be in place whenever works were less than 5 m from the rail line.

- Fulton Hogan was a rail participant, specifically a maintenance provider. Fulton Hogan carried out its work under KiwiRail’s rail licence, safety case and safety system.

KiwiRail as licensed operator and rail access provider

- KiwiRail, as the licence holder, had a duty to comply with its licence, safety case and safety system as outlined in section 11 of the Act.

-

Specifically, section 11(b) states in part:

A licence holder must:

…

(b) provide appropriate training and supervision of all rail personnel who do anything for, or on behalf of, it in respect of its rail activities, and ensure that those persons comply with—

(i) the conditions of its licence; and

(ii) its approved safety case; and

(iii) its safety system.

- The rail personnel in this instance included Fulton Hogan as the contractor and any sub-contractors that Fulton Hogan engaged to complete the tasks.

KiwiRail Safety Case

- Section 24 of KiwiRail’s safety case included a definition of ‘safety-critical tasks’ and details of the tasks of safety-critical workers. These tasks were to be undertaken in accordance with standards, rules, codes, task instructions, role profiles and job descriptions.

- Section 24 also required safety-critical workers to undertake formal training and qualify for licences to operate.

- The safety case noted that the requirements for rail-specific training, certification and re-certification were specified in:

- Rail Operating Rules and Procedures and Local Network Instructions and the Rail Operating Code, for rail operating qualifications

- the relevant codes, standards, supporting documentation and career progression plans, for engineering and maintenance qualifications.

- Section 25 of the safety case advised that KiwiRail provided an extensive range of technical and non-technical training to employees and contractors. The Learning, Design and Delivery Policy and the Operating Guidelines outlined KiwiRail’s commitment to ensuring people had the knowledge and skills necessary to perform their jobs.

- KiwiRail’s Learning and Development team was responsible for applying and reinforcing business workplace performance standards, rules and Zero Harm practices in all learning activities it designed and/or delivered.

- These responsibilities also included developing and implementing policies and procedures, assessing needs, developing and delivering courses, assessing learning and providing quality assurance on these processes

- All KiwiRail training was managed by a learning management system known as KiwiRail Learning Exchange. It included safety-critical training for employees and contractors.

KiwiRail training courses and certification

- Training courses for and the certification of RPOs formed part of KiwiRail’s safety system. To qualify as an RPO and obtain a licence to operate within the KiwiRail rail network, a trainee was required to complete prerequisite training and assessment.

- The control and oversight of all facets of the training, supervision and assessment of trainee RPOs employed by KiwiRail were managed internally by KiwiRail.

- The practical training on active worksites for RPOs employed by contractors was controlled and overseen by the contractors. KiwiRail provided theory-based training in the classroom and the OJT book, which specified the practical competencies required in the workplace. Trainee RPOs were required to achieve the OJT practical competencies under the direct and close supervision of qualified RPOs.

- Once the OJT competencies had been practised and completed, the trainee RPO’s performance was assessed by KiwiRail-appointed assessors. If an assessor considered a trainee competent, the trainee would be ‘signed off’ and issued with a licence to operate. To maintain competency, all RPOs underwent safety observations throughout their careers.

Supervision of safety-critical tasks performed by trainees

- KiwiRail required close supervision for all trainees conducting safety-critical tasks, in all aspects of its operation. These tasks included rail-protection duties conducted internally and by contractors.

- On-the-Job Training was a key part of gaining the Licence to Operate competencies contained within KiwiRail’s Rail Operating Rules and Procedures Section 10.3 and KiwiRail Safety Case Section 24. When a person was undertaking the OJT process, they were to be supervised at all times. The role of the supervisor was to ensure the protection method was being applied correctly, that there were no errors, and that coaching could be provided as required. The OJT Supervisor was required to:

- hold the appropriate Full and Final Licence to Operate for the task being observed

- have attended a KiwiRail Assessor/Verifier course or equivalent

- have been nominated by the local Operational Safety Observer (KiwiRail, 2023).

- KiwiRail’s Operational Safety Advisor and the Protection Manager (South Island) reinforced the need for close supervision of trainees conducting safety-critical work. KiwiRail advised the Commission that this message was communicated continually to KiwiRail staff and contractors.

- The safety-critical tasks undertaken by trainees remained the responsibility of the supervisor. The expectation was that, should the tasks not be performed correctly or go according to plan, the supervisor could provide the necessary guidance or intervene as required.

Qualifications of and training for supervisors

- Certain KiwiRail business groups had well-defined processes for training that included approved courses for trainers in the KiwiRail Learning Exchange. For example, all locomotive engineers undertaking duties as trainers (known as minder drivers) were required to complete the Coaching for Competency training course.

- The course was designed to equip ‘On-the-Job coaches’, trainers, minders, verifiers, buddies and approved persons with the skills and knowledge required to become effective trainers, deliver activities to support OJT and collect information for assessments.

- Importantly the course emphasised that safety-critical tasks undertaken by the trainee were performed under the authority of the supervising trainer’s ‘licence to operate’ and that trainees should never undertake safety-critical activities without direct supervision.

- While the course was available to locomotive engineers undertaking duties as trainers, it had yet to be rolled out to other business units and contractors. In addition, requirements for supervision and its definition in the context of safety-critical training were not clearly defined elsewhere.

- The supervising RPO had been employed by Fulton Hogan in that role for about 7 years. Their experience in rail protection had spanned about 15 years and their competency in rail protection was current at the time of the incident.

- A review of the supervising RPO’s competencies showed that they had not completed the Coaching for Competency training course and had not been provided with any additional training on their role as trainer.

- The supervising RPO was under the mistaken belief that the trainee RPO had undertaken the theory training and completed the tasks on previous occasions. They had formed the view that the trainee RPO was competent.

- On the day of the incident, the supervising RPO made the decision to separate from the trainee RPO when setting up the compulsory-stop protection boards. They were also not at the safe place when the trainee RPO authorised the track workers to enter the rail corridor while Train 882 entered the PWA and was on approach to the worksite.

- The Coaching for Competency training course, developed by KiwiRail Learning and Development, was designed to reinforce the role of trainers and, in the context of safety-critical tasks, ensure that trainers clearly understood that safety-critical tasks were to be undertaken only under their respective licences to operate. Although this course may not have been accessible to contractors, offering additional training for the role of supervisor/trainer was essential to gain the theoretical knowledge and practical skills required to effectively train and supervise employees.

- Had the supervising RPO been provided with training specific to their role as a supervisor of a trainee, it is likely they would have been aware of the importance of closely supervising trainees undertaking safety-critical tasks.

Supervision of trainee Rail Protection Officer

Safety issue 2: The Fulton Hogan procedures and guidelines for the supervision of trainee RPOs were inadequate. They had not provided the supervisor RPO with additional training to perform this function. This increased the risk of the trainee RPO being left unsupervised or without the required level of supervision while performing safety-critical activities for which they were not yet qualified.

- Fulton Hogan applied KiwiRail’s methodology of training RPOs, in which they were teamed up with one or more qualified and suitably experienced RPOs to observe and then learn how to undertake each task.

- During this OJT, it was expected that the trainee would receive supervision and regular feedback, gain experience and knowledge, and transition to undertaking tasks themselves while under supervision. These progressions would then be recorded in the trainee’s OJT workbooks

- Fulton Hogan viewed the supervising RPO as an experienced, qualified operator. While the company encouraged its employees to obtain further qualifications, such as New Zealand Qualifications Authority unit standards on training and assessing, there were no requirements for these to be undertaken.

- Fulton Hogan did not provide the supervising RPO with any additional training. It formed the view that the supervising RPO was competent in their role in track protection and had the necessary qualifications to undertake the training duties.

- Had the supervising RPO been provided with additional training in supervision and coaching, they would have gained a better appreciation of the requirements of the role, and this would likely have influenced their decisions in overseeing the trainee RPO.

Engineering controls for worksite protection

Safety issue 3: The track work protection in place largely relied on administrative controls, which were subject to human error. KiwiRail did not consider utilising available engineering controls to mitigate the risk of human error resulting in a rail movement entering the worksite while it was occupied by track workers.

- KiwiRail had implemented E-Protect as an engineering control on locomotives at this location. E-Protect was designed to automatically apply emergency braking and stop a locomotive in the event that a locomotive engineer did not take the appropriate actions at compulsory-stop boards of stopping and obtaining authority before entering a worksite.

- E-Protect ensured that the locomotive was halted at the compulsory-stop board location. The locomotive engineer, upon stopping and receiving authorisation from the RPO, could then proceed through the PWA. This would provide an engineering safeguard to mitigate a locomotive engineer error but would not safeguard against errors by RPOs and other track workers.

- Other engineering controls that KiwiRail had available included the Work Entry Train Alert (WETA) system (see Figure 11) – a layer of defence additional to the existing compulsory-stop protection method that provides for protection at a worksite.

- The WETA system consists of the following:

- rail sensor units equipped with track sensors that detect the presence and direction of rail vehicles passing

- central alerting units that, when activated, flash orange lights for 45 seconds and sound an alert for 20 seconds.

- repeater units for long worksites that relay the messages between all units.

- The WETA system broadcasts a message over radio channels when a train either enters or leaves a worksite. The message is relayed to the rail sensor units along the worksite and to personnel pagers unique to the system.

- The WETA system was not employed at the worksite on this occasion; if it had been, an advance warning of the approaching train could have been sent to the trainee RPO.

- The level-crossing alarm system was not a method of protection for the work being conducted. The proximity of the incident to these crossings provided early warning to the track workers and trainee RPO, and very likely reduced the consequences of the incident by giving them time to clear the worksite before the arrival of Train 882.

- Had this incident occurred in a location without a level-crossing alarm system, the track workers would not have received a warning of the train approaching the worksite at line speed.

- Had additional engineering controls been in place at the worksite, it is very likely that the trainee RPO and track workers would have been aware of the approach of Train 882.

Findings Ngā kitenga

- The trainee Rail Protection Officer authorised track workers to enter the rail corridor after having authorised Train 882 to enter the Protected Work Area and while Train 882 was still approaching the worksite. Had the trainee RPO recorded the worksite start time on the TS92 logbook, it is likely they would have remembered that Train 882 had yet to pass the worksite and would not have authorised the track workers access to the rail corridor.

- The level of supervision provided to the trainee RPO was inadequate and ineffective in ensuring that safety-critical tasks were performed safely.

- Had the supervising RPO been present when the trainee RPO authorised the track workers to access the worksite while Train 882 was approaching, it is likely that they would have detected the error and taken the appropriate action to prevent the near miss incident.

- The supervising RPO had not been provided with training to perform the function of supervisor.

- The proximity of the incident to a level crossing enabled an early warning to the track workers and trainee RPO, and very likely reduced the consequences of the incident by giving them time to clear the worksite before the arrival of Train 882.

- Engineering controls to mitigate errors by RPOs were available but not utilised at the worksite. Had an engineering control been in place at the worksite, it is very likely that the systems would have provided the trainee RPO and track workers with advanced warnings of the approach of Train 882 into the PWA and provided them with sufficient time to move to positions of safety.

Safety issues and remedial action Ngā take haumaru me ngā mahi whakatika

General

- Safety issues are an output from the Commission’s analysis. They may not always relate to factors directly contributing to the accident or incident. They typically describe a system problem that has the potential to adversely affect future transport safety.

- Safety issues may be addressed by safety actions taken by a participant. Otherwise, the Commission may issue a recommendation to address the issue.

Safety issue 1: KiwiRail, as the rail licence holder, did not take all reasonable steps to ensure that Fulton Hogan carried out track work protection in accordance with KiwiRail’s safety case and safety system. KiwiRail’s RPO training, provided to Fulton Hogan RPOs, did not describe the level or purpose of supervision of a trainee RPO.

- KiwiRail is currently undertaking a safety case replacement project to review and rewrite its safety case, actively engaging with New Zealand Transport Agency Waka Kotahi on this project.

- The Commission welcomes this safety action being taken by KiwiRail, but as the project is not yet completed, the Commission has made a recommendation in Section 6 to address this issue.

Safety issue 2: The Fulton Hogan procedures and guidelines for the supervision of trainee RPOs were inadequate. They had not provided the supervisor RPO with additional training to perform this function. This increased the risk of the trainee RPO being left unsupervised or without the required level of supervision, while performing safety-critical activities that they were not yet qualified to do.

- As no action has been taken to address this safety issue, the Commission has made a recommendation in Section 6 to address this issue.

Safety issue 3: The track work protection in place largely relied on administrative controls, which were subject to human error. KiwiRail did not consider utilising available engineering controls to mitigate the risk of human error resulting in a rail movement entering the worksite while it was occupied by track workers.

- As no action has been taken to address this safety issue, the Commission has made a recommendation in Section 6 to address this issue.

Recommendations Ngā tūtohutanga

General

- The Commission issues recommendations to address safety issues found in its investigations. Recommendations may be addressed to organisations or people and can relate to safety issues found within an organisation or within the wider transport system that have the potential to contribute to future transport accidents and incidents.

- In the interests of transport safety, it is important that recommendations are implemented without delay to help prevent similar accidents or incidents occurring in the future.

New recommendations

- On 30 April 2025, the Commission recommended that KiwiRail take all necessary steps to ensure that contractors operating under its rail licence carry out track work protection in accordance with KiwiRail’s safety case and safety system, particularly with respect to:

- supervision of trainee RPOs

- training of supervising RPOs. [039/25]

-

On 19 May 2025, KiwiRail replied:

This recommendation is accepted. KiwiRail is considering options which include enhancements to the On-the-job Training books to further ways in which the roles and responsibilities for both internal and external parties are verified and assessed.

-

On 30 April 2025, the Commission recommended that Fulton Hogan:

a. review and improve the procedures and guidelines for the supervision of trainee RPOs

b. provides appropriate training to supervisor RPOs to enable them to perform this function effectively. [041/25]

-

On 16 May 2025, Fulton Hogan replied:

Fulton Hogan has not seen the final report as requested. Fulton Hogan therefore confirms that the recommendation is under consideration. The recommendation was neither accepted nor rejected. Further consideration is required.

- On 30 April 2025, the Commission recommended that KiwiRail utilise engineering controls on track worksites to mitigate the risk of human error by track workers carrying out safety-critical tasks. [040/25]

-

On 19 May 2025, KiwiRail replied:

This recommendation is accepted. KiwiRail is working on a number of projects including the Mobile Radio Warning System (MRWS), and other engineering controls to keep track workers safe; along with opportunities to expand use of the Machine Avoidance System which is currently approved for use.

Key lessons Ngā akoranga matua

- On-the-Job Training can introduce risks to an operation. Effective supervision of trainees undertaking safety-critical tasks is an important defence against unsafe acts.

- Complex systems require robust engineering risk controls to guard against human performance limitations within the systems.

- Administrative controls, which are vulnerable to human error and non-compliance, should not solely be relied upon to keep a system safe.

Data summary Whakarāpopoto raraunga

Details

Conduct of the inquiry Te whakahaere i te pakirehua

- On 8 March 2024, the New Zealand Transport Agency Rail Safety Regulator notified the Commission of the occurrence. The Commission subsequently opened an inquiry under section 13(1) of the Transport Accident Investigation Commission Act 1990 and appointed an Investigator-in-Charge.

- The Commission issued a protection order under section 12 of the Transport Accident Investigation Commission Act 1990 and obtained documentation and records including:

- Tranzlog data of the locomotives, signal logs, train control voice recordings and GPS logs

- training records

- completed documentation

- standards, rules and procedures.

- Commission investigators attended the site on 12 March 2024 and conducted a site investigation.

- The Commission conducted interviews with track workers, rail protection officers, train crew and competency managers.

- On 28 November 2024 the Commission approved a draft report for circulation to seven interested parties for their comments.

- Three interested parties each provided a detailed submission, and three interested parties replied that they had no comment. The remaining interested party did not respond despite efforts to contact them. Any changes as a result of the submissions have been included in the final report.

- On 30 April 2025, the Commission approved the final report for publication.

Glossary Kuputaka

- Compulsory-stop protection

- A sequence of boards used to protect rail personnel and rail vehicles from entering a planned Protected Work Area

- Conduits

- A tube or trough for protecting electric wiring

- Daily Information Bulletin

- A controlled instruction, printed, typed or handwritten, issued by those authorised by the Rail Operating Rules

- DOWN direction

- Trains running away from Otiria in the North Island and away from Picton in the South Island are travelling in the DOWN direction.

- GeVis

- A KiwiRail software application that displays dynamic geographical location of trains on the network. It is a source of information and is not designed for use as a safe-working system.

- E-Protect

- E-Protect is a system on locomotives that uses Global Positioning System (GPS) technology to monitor the speed of trains approaching compulsory-stop boards (CSB) and applies a penalty brake if a train does not stop at the CSB location. The system is designed only to enforce a stopping sequence. Once the train has stopped, the E-Protect system becomes inactive, allowing the train to be moved through the PWA. The placement of the compulsory-stop protection boards is a necessary reminder for locomotive engineers to prepare their trains for stopping at designated places to avoid emergency brake applications.

- Hydrovac truck

- A vacuum excavator truck purpose-built for non-destructive digging and locating underground service.

- Licence holder

- A person who is required to hold a licence under Section 15 of the Railways Act 2005 and has been granted a licence under Section 17 of the Railways Act 2005

- Lock-on frame

- A metal frame device that contains numbered locations where individually assigned padlocks are attached, to signify that a padlock owner is occupying the Danger Area within a PWA. Before the RPO authorises personnel to leave the safe place, they must attach their RPO padlock to the lock-on frame handle. All personnel and visitors on site must then attach padlocks for themselves before leaving the safe place, and padlocks for any vehicles under their control that will foul the track. When clearing the track for a rail movement (train), personnel must secure vehicles under their control in a safe mode, clear of the track, before returning to the safe place and locking off. After removing their padlock, personnel must not foul the track until they are authorised to resume work by the RPO. The requirement to use the system was contained in KiwiRail’s Track Safety Rule 902(g).

- Maintenance provider

- A person who provides maintenance services for any railway infrastructure or rail vehicle, whether or not that person engages rail personnel to do so on its behalf.

- Mobile-plant controller

- A person responsible for authorising the movements of mobile plant within a worksite

- On-the-Job Training (OJT)

- The placement of a trainee with a licensed practitioner in actual operations to carry out safety-critical tasks. The purpose of this training is for the trainee to gain exposure to a range of experiences and become fully competent in the designated tasks.

- Permit to enter

- The necessary authority required for working in, or impacting on, KiwiRail rail operational areas, unless working under direct KiwiRail supervision

- Protected Work Area (PWA)

- A section of line or lines where rail personnel carry out activities using an approved protection method

- Protected Work Area Logbook

- A record required to be completed when undertaking protection duties using compulsory-stop protection

- Rail corridor

- The land between the legal boundaries of railway land or land within 3 metres (m) of the centreline of any operational track where the land boundary is less than this distance.

- Rail movement

- The operation on rail of rail traffic

- Rail operator

- Provides or operates a rail vehicle, whether or not it engages rail personnel to do so, or to assist in doing so, on its behalf. It does not include those rail personnel.

- Rail participant

- Section 4 of the Railways Act 2005 defines a rail participant to mean any of the following: (a) an infrastructure owner (b) a rail vehicle owner (c) a railway premises owner (d) a rail access provider (e) a rail operator (f) a network controller (g) a maintenance provider (h) a railway premises manager (i) any other class of person prescribed as a rail participant by regulations.

- Rail personnel

- In relation to a rail participant, means an individual engaged by the rail participant or by an agent or contractor of the rail participant, whether as an employee, agent, contractor, or volunteer, for the purposes of carrying out, or assisting in carrying out, rail activities of the rail participant.

- Rail Protection Officer (RPO)

- The person with overall responsibility for providing rail protection for the Protected Work Area

- Risk control plan

- Documentation relating to Fulton Hogan’s internal processes of documenting and managing risks on a worksite, incidental to the Rail Protection Officer’s duties

- Safe place

- A place where people and equipment cannot be struck by passing rail traffic.

- Safety case

- A comprehensive document that outlines the safety risks associated with a system or installation and explains how these risks are managed

- Safety-critical

- Activities that, if not performed correctly, could lead to serious harm or injury.

- Safety-critical workers

- A worker whose action or inaction may lead directly to a serious incident affecting the public or the rail network.

- Safety observations

- ‘In the field assessments’ of rail personnel applying practical skills to activities specified in their licences to operate

- Safety system

- A written record of all the management and operational policies and practices that relate to the safe conduct of rail activities, including the operational and training manuals.

- Shunt

- A generic term for the movement of locomotives, wagons and carriages using a purpose-built railway engine (shunt)

- Compulsory-stop board

- A safe-working notice board inscribed ‘stop’ and/or displaying a red coloured symbol, at which all trains must stop and must not pass until authorised.

- Track workers

- Competent workers whose primary duties are associated with work on or around infrastructure in the rail corridor.

- UP direction

- Trains running towards Otiria in the North Island and towards Picton in the South Island are travelling in the UP direction

- Protected work area

- A section of line or lines where rail personnel are carrying out activities using an approved protection method

- Worksite

- An area with defined limits that is protected so that work can be undertaken.

Citations Ngā tohutoru

Australian Transport Safety Bureau. (2017). RI-2014-011 Safe work on track across Australia: Analysis of incident data, 2009 – 2014.

KiwiRail. (2023). Track Protection Competencies Overview, p.7.

Transport Accident Investigation Commission. (December 2016). Rail inquiry RO-2014-104 Express freight train striking hi-rail excavator within a protected work area, Raurimu Spiral, North Island Main Trunk line, 17 June 2014.

Transport Accident Investigation Commission. (January 2022). Rail inquiry RO-2020-104 Safe Working Irregularity, East Coast Main Trunk Line, Hamilton – Eureka, 21 September 2020.

Transport Accident Investigation Commission. (March 2024). Rail inquiry RO-2023-103 Safe-working irregularity, 3.85 km mark, Johnsonville line – tunnel 5, 04 May 2023.

Transport Accident Investigation Commission. (May 2020). Rail inquiry RO-2019-101 Safe-working occurrence, Westfield yard, Ōtāhuhu, Auckland, 24 March 2019.

Appendix 1. Daily Information Bulletin

Appendix 2. TS90 Work Site Register, lock-on frame and colour coded padlocks used

Appendix 3. Managing a Protected Work Area Job Aid – Single Work Site

Appendix 4. Railways Act 2005

Related Recommendations

On 30 April 2025, the Commission recommended that KiwiRail take all necessary steps to ensure that contractors operating under its rail licence carry out track work protection in accordance with KiwiRail’s safety case and safety system, particularly with respect to: a. supervision of trainee RPOs b. training of supervising RPOs.

On 30 April 2025, the Commission recommended that KiwiRail utilise engineering controls on track worksites to mitigate the risk of human error by track workers carrying out safety-critical tasks.

On 30 April 2025, the Commission recommended that Fulton Hogan: a. review and improve the procedures and guidelines for the supervision of trainee RPOs b. provides appropriate training to supervisor RPOs to enable them to perform this function effectively.