Passenger train parts at low speed, inspection and response gaps exposed. A cracked coupler, unnoticed in maintenance, caused carriages on the TranzAlpine tourist train to part. Power braking stress, missed alarms, and no procedure for crew to deal with partings revealed wider risks.

Executive summary Tuhinga whakarāpopoto

What happened

- On 17 December 2023 at 1415 (Times are in New Zealand Standard Time (co-ordinated universal time + 13 hours) and expressed in 24-hour format) the TranzAlpine passenger train (the passenger train service between Christchurch and Greymouth operated by KiwiRail) departed Greymouth on its scheduled service back to Christchurch.

- An earlier mechanical issue with one of the two locomotives resulted in two additional locomotives being attached at Otira Station for supplementary power to Arthur’s Pass station.

- At approximately 1630 as the train descended into Arthur’s Pass station, the locomotive engineer completed several train brake applications.

- As the train came to a stop at the station’s platform, the first two carriages parted by approximately one metre (m), activating the fail-safe braking system.

- The train crew members were unaware of the parting until an onboard crew member went to walk between the two carriages. No passengers or crew were injured when the train parted.

Why it happened

- A single component of the carriage-coupler system broke, causing the two carriages to part.

- The broken component had a pre-existing fracture that had not been identified in regular maintenance inspections by KiwiRail.

- It is virtually certain that the train’s configuration of four locomotives7 operating in throttle position three while applying the train’s brakes to their full capability caused the weakened coupler component to break.

What we can learn

- Adequate inspection and maintenance plans for safety-critical components are vital to ensure components remain in a condition fit for their intended purpose.

- Preprepared and practised response plans9 assist in an incident to ensure appropriate action can be undertaken safely.

Who may benefit

- Rail operator personnel, transport designers and maintainers of safety-critical components may benefit from the findings in this report.

- Any personnel involved in preparing or implementing response plans.

Factual information Pārongo pono

Background

- The TranzAlpine passenger train service is a tourist service that departs Christchurch daily during peak season at 0815, travelling to Greymouth before returning to Christchurch later that evening (see Figure 3). The return journey takes approximately 10 hours 45 minutes conveying between 9 and 12 carriages.

-

The TranzAlpine service requires the following train crew for the running of its day-to-day operations (see Figure 4).

Figure 4: TranzAlpine service train crew

Narrative

- On 17 December 2023 at about 0715, the TranzAlpine passenger train (the train) arrived at Christchurch station. The train crew completed a train examination and tested the air brakes confirming the train was safe to operate before passengers and onboard crew boarded the service.

- Passengers and the onboard crew boarded the train and at 0820 the train departed Christchurch station. Shortly after departing, the second locomotive of two at the head of the train experienced a traction-motor ground-relay fault in one of the six electrical motors, causing a sudden jolt and temporary loss of power.

- The locomotive engineer (LE (1)) was able to continue driving the train for approximately 10 kilometres (km) to the next station. At the station LE1 isolated the second locomotive’s power supply (the isolation switch is located in the cab of the locomotive and has three operating positions: engine start-stop, engine run and isolate). The train continued on to Greymouth with one operating locomotive and no further mechanical issues arose.

- At about 1310, the train arrived at Greymouth station where the passengers disembarked. The empty train was moved to Greymouth rail depot to reposition the two locomotives on the opposite end of the train for the return journey to Christchurch.

- Once repositioned, LE (4) identified that the now leading locomotive had its power supply isolated. Unaware of the earlier mechanical fault, they changed the locomotive’s operation switch to the run position.

- The train departed Greymouth at 1415 with 64 passengers onboard and LE (5) now driving the train. Because of the earlier fault, the Otira train crew (consisting of two locomotive engineers and one rail operator who work between Otira and Arthur’s Pass) arranged for two additional locomotives to be added to the train to supply additional power up through the Otira tunnel.

- The train arrived at Otira at approximately 1600. The Otira train crew took over from LE (5) and added the two additional locomotives to the front of the train (four in total). They also added two locomotives to the rear of the train, as required by KiwiRail’s operating procedures for travelling through the Otira tunnel (see Figure 5). The rear locomotives, while not required to supply power up through the tunnel, were attached for emergency use if needed.

- The Otira train crew were unaware that the faulty locomotive had been switched back into the run position. This allowed all four locomotives at the front to supply power to their traction motors.

- At 1604, the train departed Otira traveling at 40 kilometres per hour (km/h) through the Otira tunnel with no issues.

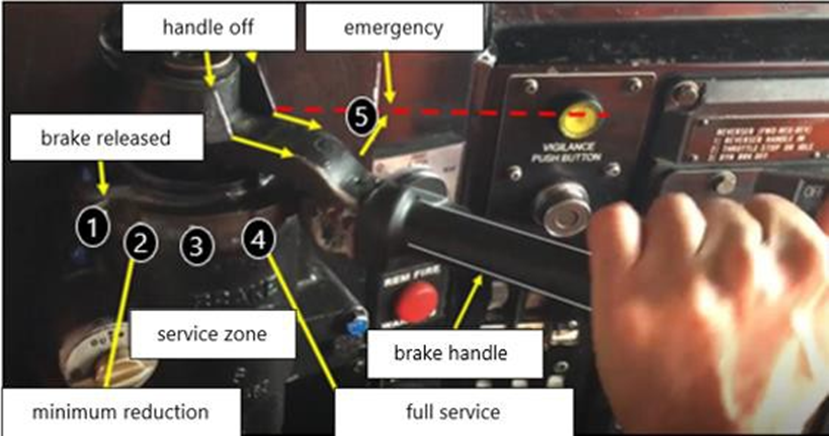

- At about 1631:05, the train exited the Otira tunnel at Arthur’s Pass travelling at 25 km/h. The LE (2.0) reduced the throttle position from five down to three (of the available eight positions) in preparation to stop at the station’s platform (see Figure 6).

- The train crossed rail bridge 49 at 26 km/h (see Figure 7). The LE (2.0) further reduced the throttle position to two, while applying the minimum setting to the train’s brakes.

- The LE (2.0) moved the lead locomotive’s independent brake handle manually downwards removing the brakes from the first, second and fourth locomotives while leaving the brakes applied to the train’s carriages stretching the train in preparation to stop at Arthur’s Pass station.

- At 1631:44, the train’s speed reduced to 20 km/h as it started the gradual descent into Arthur’s Pass station.

- LE (2.0) applied a further brake application to the train’s brakes. They also moved the lead locomotive’s independent brake handle manually downwards, removing the brakes from the first, second and fourth locomotives.

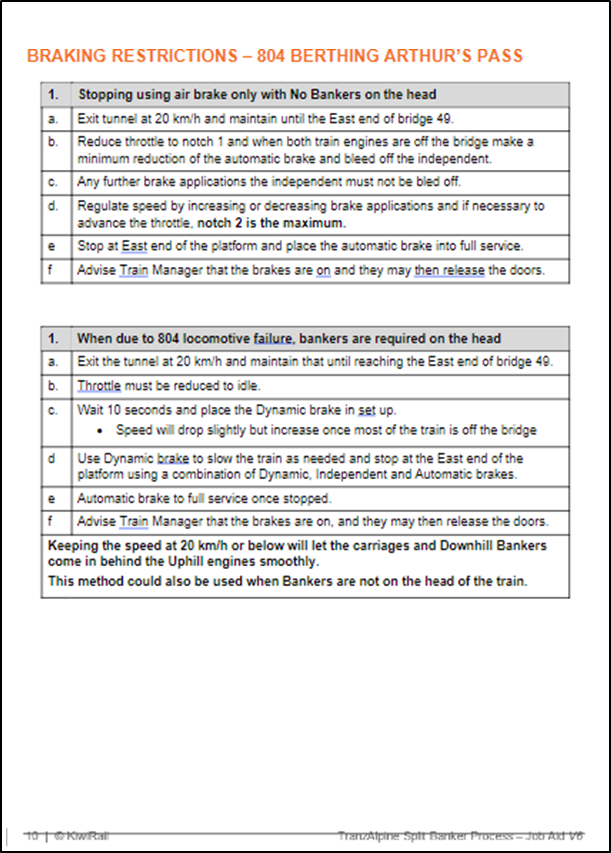

- They then moved the throttle into position three; in doing so they were operating outside KiwiRail’s operating code and approved train handling practices (see Appendix 2).

- At 1632:20, the train entered Arthur’s Pass station travelling at 12 km/h. LE (2.0) moved the brake into full-service brake position, applying all available brakes on the train including the four locomotives and all carriages, while remaining in throttle position three.

- At 1632:29, while travelling at approximately 3 km/h, the first and second carriages parted when the coupler tailpin broke (see Figure 8) causing carriage one’s drawgear and coupling system to be pulled out from its chassis and remain attached to carriages two’s coupler drawgear.

- This caused the front portion of the carriage’s spring-pack shock absorber system (that dampens in-train coupler forces) to fall out from the chassis housing onto the track below (see Figure 9).

- As a result of the parting, the carriage’s brake pipe uncoupled and the 400 volt (V) power-connection lead broke from its housing, causing carriage one to lose its power supply (see Figure 10).

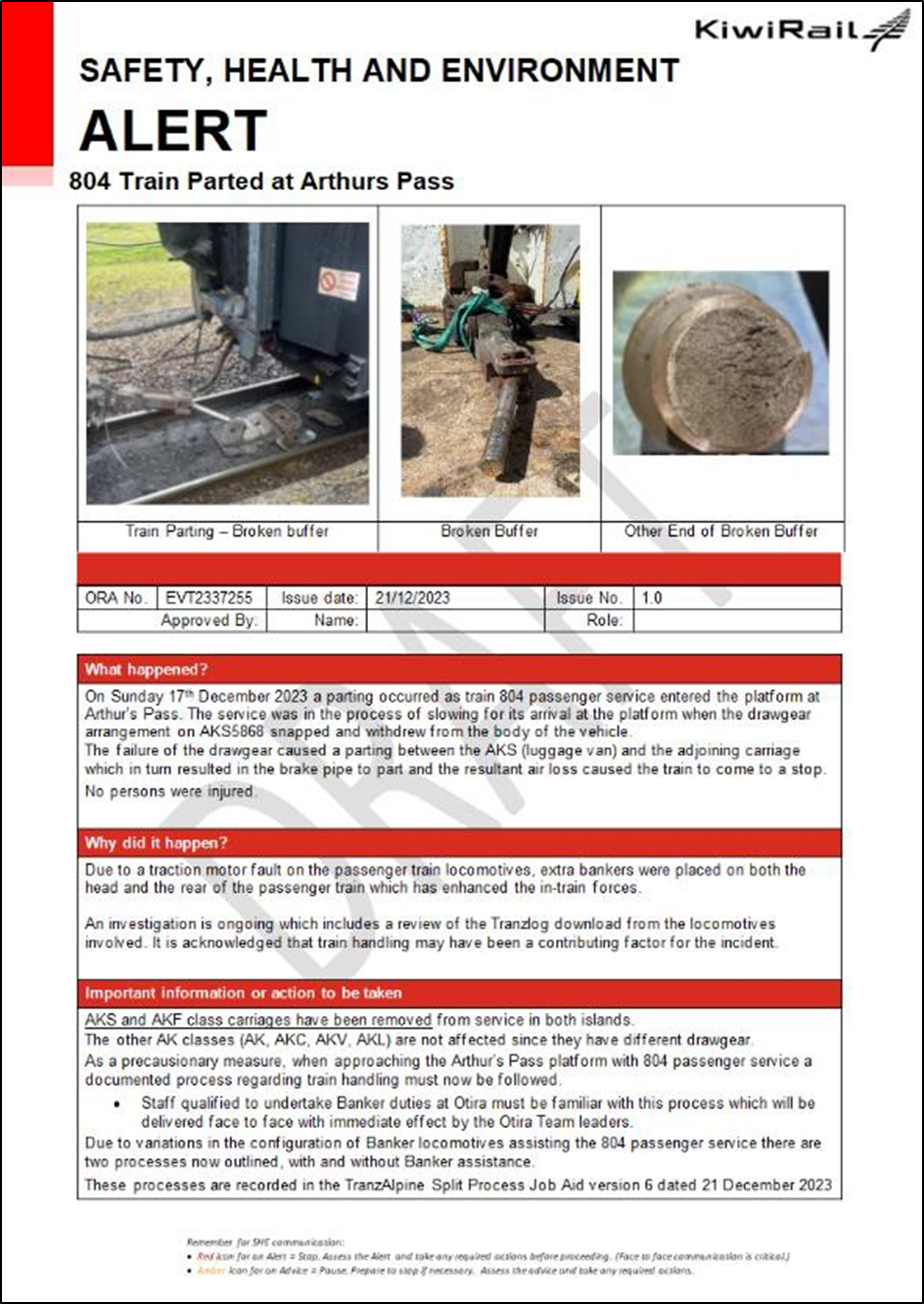

- The Train Management System (TMS) data cable remained connected, along with the main reservoir air hose supplying air pressure to the carriage’s suspension and other components (see Appendix 1 for KiwiRail’s safety alert notification).

- The parting activated the train’s emergency brake fail-safe system, applying maximum braking force throughout both portions of the parted train.

- At 1632:32, the train came to a stop with the first and second carriages parted by approximately 1 m.

Action after the parting

- As the train stopped, the oncoming LE (6) (operates the train between Arthur’s Pass and Christchurch) went between the second and third locomotives to uncouple the two front assisting locomotives, unaware that the train had parted.

- As part of the uncoupling process, LE (6) lifted the air source tap levers that control air pressure to the train’s brakes. Coincidentally, this had the effect of preventing the brake air pressure falling to a level that would have triggered an automatic alert to train control that the brake air pressure had been lost.

- The onboard crew, unaware of the parting, continued with preparations for passenger boarding.

- A crew member then moved through carriage two (the AKF kitchen carriage) to enter carriage one (the AKS luggage storage carriage) and in doing so, discovered that the carriages had parted (see Figure 11).

- The crew member walked back through the carriage to alert other crew members, who then used a handheld radio to alert the Onboard Staff Manager (OSM) and the Train Manager (TM) of the parting.

- The OSM and TM gathered the Otira train crew and oncoming LE (6) at the parted carriages and made a recovery plan to move the parted portions of the train back to Christchurch separately.

- The recovery plan of the parting incident was overseen by the Christchurch Linehaul Operations Manager (LOM) and the Line Service Manager (LSM), but did not involve the Rail Incident Co-ordinator (RIC) or any mechanical staff.

- In preparation to travel back to Christchurch, the Otira train crew removed the broken coupler connected to carriage two and secured the carriage’s loose power and data cables, which could not be removed (see Figure 12). The crew completed a brake test for carriage one before the oncoming LE (6) departed Arthur’s Pass station with carriage one and two locomotives.

- The Otira train crew repositioned the two additional locomotives onto carriage two and the remainder of the train. A brake test was completed before LE (2.1) departed for Christchurch.

- No crew or passengers were injured when the train parted. Carriage one sustained damage to its chassis housing and the carriage-coupler system.

Personnel information

- The LE driving the train at the time of the parting, LE (2.0), had nine years’ experience and had been employed by KiwiRail since March 2014. They had recently undergone a safety-observation assessment and was certified for the role of a TranzAlpine LE.

Train/vehicle information

- The train was 297 m long and weighed 999 tonnes (t) at the time of the incident. It was powered by four DX class diesel electric locomotives, hauling nine carriages and two locomotives attached to the rear that were not under power.

- Carriage one was an AKS luggage-storage carriage. Carriage two was an AKF kitchen carriage. Only onboard crew members were authorised to enter these carriages.

- The remainder of the train consisted of passenger and viewing deck carriages.

- Between 2019 and 2023, carriages one and two had been repurposed from the Auckland passenger SA class fleet into the TranzAlpine service.

Recorded data

- The front locomotive was fitted with a Tranzlog data recording system. The Transport Accident Investigation Commission (the Commission) obtained and analysed the Tranzlog data (see Figure 13). See Section three for discussion of the Tranzlog data.

|

Tests and research

- KiwiRail commissioned metallurgical testing on carriage one’s tailpins and provided a copy of the test results to the Commission (discussed in section three).

- KiwiRail also conducted train simulation coupler force testing and provided the results to the Commission (also discussed in section three).

Organisational information

- KiwiRail Holdings Limited (KiwiRail) is a New Zealand state-owned enterprise operating trains and rail vehicles, controlling rail movements on the national rail network and maintaining the railway infrastructure as the rail access provider.

Previous occurrences

- The Commission obtained data from 2013 to 2023 on New Zealand passenger train partings (see Figure 14). This data showed that partings predominantly involved automatic type couplers with a manual release handle and locking pin (the coupler type in carriage one). Fewer partings involved semi-permanent couplers with pneumatic and electrical interlocking connections used on commuter services.

RO-2021-103, Te Huia train parting

- At 1651 on 19 July 2021, the second and third carriages parted on a KiwiRail-operated Auckland to Hamilton passenger train (Te Huia) travelling at 91 km/h. The parting occurred at about 636.9 km between Papakura and Pukekohe on the North Island Main Trunk (NIMT), causing the brakes to automatically apply in both train portions as air hoses between the carriages separated. There were no injuries, but there was some damage to inter-carriage electrical jumper cables.

- On 16 November 2022, the Commission recommended that KiwiRail provide guidance to staff responding to the severance of inter-carriage jumper cables during the parting of passenger trains, to ensure any damage to safety-critical trainline circuits is considered, and any necessary safety action is taken before moving the train.

RO-2005-115, passenger train parting

- On Friday 1 April 2005, Train 2100, an empty passenger service, was being positioned to Waitakere to start passenger operations for the day. At 0627, soon after the train had passed through Ranui station, the coupling between the locomotive and the guard’s van parted. As a result of the parting, the automatic brake system lost all air pressure and brought the train to a stop.

- The Commission recommended that with the trend towards fixed passenger-train consists, Toll NZ (the then operator) investigate compliance with, and the robustness of, present procedures for the checking of coupled drawgear heights with a view to reinforcing existing procedures and, if need be, introducing additional or changed processes to further reduce the likelihood of passenger-carrying vehicles operating in service with an out-of-code drawbar height.

Analysis Tātaritanga

Introduction

- On 17 December 2023, the TranzAlpine passenger train unintentionally parted at Arthur’s Pass station as the train was preparing to stop at the station’s platform. There were no injuries, but the parting caused significant damage to the carriage chassis and coupler connection, which was pulled out.

- The following section analyses the circumstances surrounding the incident to identify those factors that increased the likelihood of the incident occurring or increased the severity of its outcome. It also examines the safety issues identified, which have the potential to adversely affect future operations.

- The Commission identified safety issues in the following areas:

- the maintenance of safety-critical components

- passenger-train alarm systems

- the safe operation of rail vehicles after an incident.

LE training to manage in-train forces

- Managing in-train forces is a crucial part of maintaining operational safety and efficiency when driving a train. Effective train handling practices prevent excessive movement between the carriage couplers when traversing the track.

- New Zealand track topography and gradients vary. Locations such as Auckland and parts of the east coast of the South Island are relatively flat while the Midland line between Otira and Arthur’s Pass has the steepest gradient of track in the country, being a 1 in 33 gradient.

- Managing and minimising the in-train forces, being the inward force (buff compression force) and outward force (draft tensile force) (see Figure 15), is essential to mitigate the risk of unintended movements that could potentially derail or part the train, and for passenger comfort.

- In-train forces can be exacerbated when bringing the train to a complete stop. Careful consideration is required when using the train’s brake and the locomotive’s throttle power setting to minimise the forces applied to carriage couplers.

- The training provided to KiwiRail’s LEs covers the following principles of train handling:

- locomotive pairings and horsepower availability

- locomotive power and traction amp load settings

- air brake and dynamic brake configurations

- consist length and load weight configuration

- wagon and carriage types, coupler connection strength combinations

- track gradient, curvatures and speed restriction locations.

- KiwiRail’s theory and practical assessments required trainee LEs to demonstrate train handling principles effectively before undertaking on-the-job training. This included controlled simulated runs to ensure no more than 128 kilonewtons (kN) of force was applied to the train’s coupler connections.

- The LE operating the train at the time of the parting, LE (2), completed theory, freight-simulator and passenger training assessments in 2014. They were certified competent to drive passenger trains in 2019 and completed additional on-the-job training when moving depots to Otira. This included operating four locomotives attached to the front of the TranzAlpine passenger train.

- On the day of the incident, the train’s normal locomotive configuration was increased from two to four locomotives (see Figure 16). While not common practice for the passenger service, this configuration was within KiwiRail’s Operating Rules. If being operated in this configuration, the rules at the time required the third locomotive’s power supply to be isolated, which did not occur on the day of the incident.

- The train then had two locomotives attached to the rear carriage, as required to travel through Otira tunnel. The train’s total weight was then 999 t, with 591 t located behind carriage one’s coupler at the front of the train.

- The slight downward gradient towards Arthur’s Pass station combined with the application of the train brakes, and having power applied to all four locomotives, stretched the train and applied draft tensile force to the carriages. This method of slowing the train is commonly used with limited or no throttle power, when the front locomotive’s independent brakes are manually removed, commonly known as ‘bailing off’ the brake application.

- As further brake applications were made, the braking force increased (see Figure 17). The front four locomotives remained in throttle power three, generating a motive force in the opposing direction.

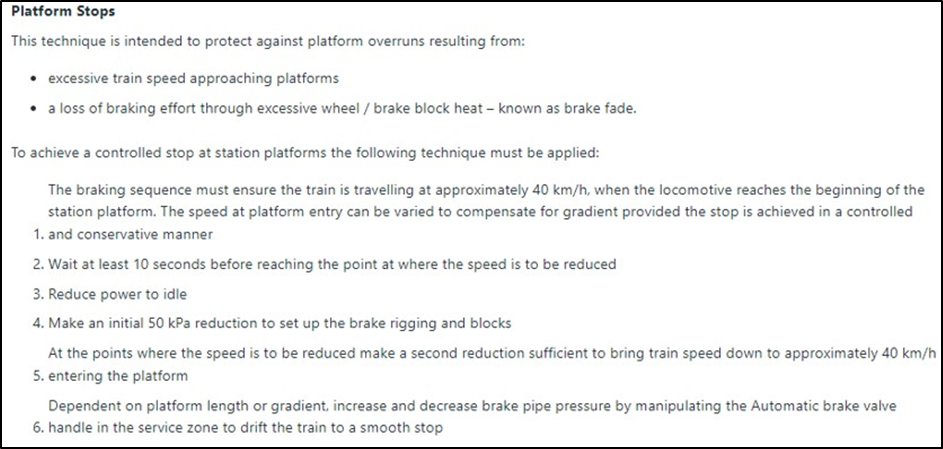

- The train was equipped with a graduated train brake, allowing the LE to apply and remove the braking force as required to bring the train to a smooth stop. Use of the graduated train brake system is documented in KiwiRail’s train handling guidelines (the guidelines) and is part of the simulation training module for passenger LE training.

- Analysis of the Tranzlog data showed that the LE’s use of the graduated train brake and throttle power when approaching Arthur’s Pass station did not follow the guidelines and increased the force applied to the carriage couplers (see Appendix 3 for the train’s air brake response functions) (see Figure 18).

- Simulator testing conducted by KiwiRail indicated that approximately 516 kN of draft tensile force was put on the coupler connection between carriage one and carriage two when replicating the train’s approach to Arthur’s Pass station on the day of the incident.

- Simulator testing conducted by KiwiRail indicated that approximately 99 kN of draft tensile force was put on the coupler connection between carriage one and carriage two when operating the graduated braking system in accordance with the guidelines.

- In response to the incident, KiwiRail produced a Job Aid instruction for LEs to reinforce the approved procedures for stopping passenger trains at Arthur’s Pass station (see Appendix 4).

Testing of the failed carriage-coupler component

- Quest Integrity NZL Limited carried out testing for KiwiRail on the material composition and cause of failure of the tailpin from carriage one.

- The tailpin (see Figure 19: Tailpins from each end of carriage one) transmits draft tensile forces and buff compression forces from the drawbar to the spring pack and therefore the carriage chassis.

-

The approximate length of the tailpin was 538 mm from the centre of the eye to the end of the thread. There was moderate and irregular surface wear and corrosion on the tailpin (see Figure 20).

- The material grade was identified as medium carbon steel, having low fracture-toughness properties (little or no margin against brittle fracture) at operating temperature. The carbon content was slightly above the maximum allowed by EN 8 (equivalent to BS979:1983 60M40, or AISI 1040) specification; however, all other material aspects were consistent with specification EN 8.

- The tailpin was slightly bent in the horizontal plane. While the Commission was unable to determine the cause of the bend, examination of the fatigue crack indicates that the bend was very likely present before the fracture occurred (see Figure 21).

- The drawbar pin, which connects the drawbar to the tailpin, was deformed and worn with surface rust (see Figure 22).

- The testing indicated that it was virtually certain that the failure of the tailpin was caused by a brittle fracture, initiated by a pre-existing fatigue crack. The fatigue crack originated from the thread root (see Figure 23), on the inner curve of the bent tailpin.

- The draft tensile force put on the tailpin during operations acted to straighten it. This additional force on the inner curve of the tailpin led to the initiation of a fatigue crack (see Figure 24). The characteristic of the fracture suggests a load of between 406 and 465 kN was applied during the failure.

Repurposing rail vehicles

- Repurposing rail vehicles is a common practice in New Zealand and around the world. In New Zealand, the repurpose process is overseen and approved by NZ Transport Agency Waka Kotahi (NZTA).

- The process to change, design, construct or reintroduce a rail vehicle requires the rail licence holder (owner of the rail vehicle) to complete a change or variation notification form (a formal way to let NZTA know about a planned change or renewal that could affect the safety of rail activities and is within the current scope of an approved safety case). The change notification or variation form records what changes are being sought from the approved safety case.

- Carriage one was built by British Rail Engineering Limited at Derby carriage and wagon works between 1971 and 1975. A total of 1,876 such carriages were built and were known as the BR MII carriage fleet. They were Britian’s commuter passenger fleet and operated across Britain’s rail network between 1971and 1990 before being decommissioned (a rail vehicle taken out of service) (see Figure 25).

- In 1995 TranzRail, New Zealand’s rail provider at the time, imported 150 of the decommissioned BR MII carriages from British Rail, repurposing them for Auckland’s commuter fleet and the Capital Connection passenger train service. Once refurbished, they were reclassified as the SA class carriage (see Figure 26).

- The refurbished carriages retained some original parts from the BR MII fleet, including:

- the spring pack and tailpin connection system

- the coupler and drawgear system.

- Between 2014 and 2016, KiwiRail decommissioned the SA class carriage fleet. Then in 2019, KiwiRail sought to repurpose the SA class carriages for both:

- the Te Huia passenger service between Hamilton and Auckland

- kitchen facility carriages (AKF) and storage carriages (AKS) in their ‘Scenic Journey’ fleet.

- KiwiRail submitted a change notification form to NZTA on 16 December 2019, to repurpose three SA class carriages to the requirements of an AKS class carriage (see Figure 27). NZTA reviewed and accepted the change notification three days later on 19 December 2019.

- The first AKS class carriage was commissioned and tested by KiwiRail in December 2019 and from 2020 it was included on the TranzAlpine train service (see Figure 28).

- The TranzAlpine service operates on the South Island’s Midland line, which is exposed to extreme hot and cold temperatures and has New Zealand’s steepest track gradient.

- KiwiRail’s assurance testing for the AKS class carriages included a coupler risk assessment of all coupler parts to assure they were compliant and fit for purpose. Other components included in the assessment were:

- drawbar height

- drawgear strength

- standard types of drawgear

- non-standard drawgear

- brake-line couplings.

- KiwiRail Operating Rules specify a maximum load of 600 t behind the leading coupler connection for all A class carriages when travelling in a normal passenger service. The AKS class carriage was classified as an A class carriage but had an S class coupler connection. The S class coupler connection had a load limit of 20 vehicles, being approximately 620 t.

- On the day of the incident, the AKS carriage (carriage one) was the leading carriage behind four locomotives. This meant that the carriage’s coupler had approximately 591 t of weight attached to it.

- The Commission found that when repurposing the SA class carriages to AKS class carriages, KiwiRail’s assessment of the ability to operate the carriages under the conditions experienced with the TranzAlpine passenger service was inadequate and did not identify all the risks, in particular:

- the train handling parameters of the coupler connection

- ability to detect damage to safety critical components

- any change to the frequency of maintenance inspections

- maximum load configuration with other rail vehicles

- track gradient and coupler kN force limitations

- limitations on operating in a wide range of temperatures.

- The inadequate assessment meant that an opportunity to identify and mitigate the risks of operating in these conditions was missed.

Maintenance of carriage components

Safety issue 1: The maintenance and inspection of carriage-coupler connections was inadequate to identify existing faults in safety-critical components. This increased the risk of failure of the components during operation.

- Effective regular maintenance of safety-critical components on rail vehicles ensures that they operate safely on the rail network. Maintenance programmes should identify and meet manufacturers’ standards, accepted engineering practices and industry guidance. This ensures components remain fit for purpose within their operational life.

- KiwiRail had a daily, time-based and kilometre-based maintenance inspection programme in place for the AKS class carriages at the time of the incident. The maintenance inspection programme was part of the 2019 change-notification documentation supplied to NZTA when the carriages were repurposed.

- KiwiRail’s maintenance inspection programme required a visual inspection of the carriage coupler and the end portion of the tailpin, being the only part exposed. The coupler and tailpin of the AKS class carriage involved in the incident (carriage one) had been inspected in accordance with the maintenance inspection programme.

- The internal parts of the carriage coupler were not inspected at any stage of the maintenance inspection programme (see Figure 29).

- Independent testing found the tailpin of carriage one had a pre-existing fatigue crack, reducing its integrity and increasing the likelihood of failure. The maintenance inspection programme did not require the removal of the tailpin from the spring pack or removal of the drawbar pin, so not allowing the condition of the tailpin and drawbar pin to be fully inspected.

- Had KiwiRail’s maintenance inspection programme included removing, inspecting and testing of the entire tailpin it is very likely that the pre-existing fatigue crack would have been identified and the tailpin and drawbar pin replaced.

Carriage alarm warning system

Safety issue 2: The train’s alarm system (TMS) did not alert the crew that the train had parted. This meant the onboard crew continued with their duties unaware of the risk to themselves and passengers.

- Rail transportation is a complex system (a complex system is one where multiple individuals and components interact. Within complex systems, safety is considered to be an emergent property of the system as a whole, not the result of individual components acting in isolation) and one that requires robust risk controls to guard against human performance limitations and system and mechanical failures. Administrative controls alone, which are vulnerable to human error or non-compliance, should not be relied upon to keep the system safe.

- In this incident, the existing alarm system did not alert the onboard crew that the carriages had parted.

- The TranzAlpine passenger train was fitted with a Train Management System (TMS) connecting each carriage into a computer system. Part of the TMS function was to alert onboard crew to operational faults through an audible alarm located at each end of the carriages. Upon hearing the alarm, it was the role of the TM to respond. A TMS display panel was located at the entry and exit points of each carriage.

- The TMS display panel records the fault and the TMS sounds a siren for approximately four seconds before it stops. The TMS is not programmed to continue sounding the alarm and did not require any action to acknowledge the alarm.

- When Commission investigators simulated the parting, with the brake pipe and power lead disconnecting, they recorded the TMS sounding for approximately four seconds and the TMS display panel indicated “FAULT END 1 DIRECTION” (see Figure 30).

- On the day of the incident, it is very likely the alarm activated as required. However the TM did not recall the TMS display activating or the TMS alarm sounding when the train parted.

- The alarm activation period of four seconds was short, during which the crew continued with their duties. Research shows that different alarm types and durations should be considered when they are associated with a safety risk (see citations).

Recovery response

Safety issue 3: KiwiRail’s processes and procedures to respond to a train parting because of mechanical failure were inadequate and increased the risk of injury to rail personnel and damage to rail vehicles.

- Adequate processes and procedures for incident or accident recovery are vital to ensure the safety of rail personnel and rail vehicles.

- KiwiRail’s Operating Rules allowed certified personnel to recouple undamaged components following a parting, but did not address a mechanical coupler failure, such as a broken coupler.

- KiwiRail’s rail incident response manual for RICs also did not address a mechanical coupler failure.

- In response to the parting of carriage one and carriage two, KiwiRail personnel planned and implemented the recovery of the two portions of the train. No certified mechanical staff were involved and there was no inspection of the carriages to ensure it was safe to relocate them to Christchurch.

- Carriage one was returned to Christchurch with broken and loose coupler components remaining in the carriage’s chassis.

- KiwiRail Operating Rule 2.2 required a person certified for second person duties to accompany any empty passenger service being conveyed on the rail network, to ensure any TMS activations enroute were communicated to the LE and the fault rectified or mitigated by qualified personnel (see Figure 31).

- The crew that conducted the recovery of the parted train were not aware of the empty passenger services requirement under Operating Rule 2.2 and no certified second person was assigned to the single carriage when it was travelling back to Christchurch.

- This meant the approved process of risk management was not followed, potential risks controls were not in place when the carriage was repositioned, and onboard crew would not have been able to respond if an issue arose during the journey.

- If KiwiRail’s Operating Rules included the procedures to be followed in a mechanical coupler failure, and the crew were trained in those procedures, it is likely that the hazards of returning the parted train to Christchurch would have been identified and mitigated.

Findings Ngā kitenga

- As the TranzAlpine passenger train approached Arthur’s Pass station, carriage one and carriage two of the train parted when the coupler tailpin between the carriages failed.

- It is virtually certain that at the time of the incident, the tailpin was in a weakened condition because of a pre-existing fatigue crack.

- It is virtually certain that the operation of the train’s four locomotives in throttle position three while applying the train’s brakes fully caused the brittle fracture of the weakened tailpin.

- When repurposing the SA class carriages to AKS class carriages, KiwiRail’s assessment of the ability to operate the carriages under the conditions experienced by the TranzAlpine service was inadequate and did not identify all the risks.

- Had KiwiRail’s maintenance inspection programme included removing, inspecting and testing the entire tailpin it is very likely that the pre-existing fatigue crack would have been identified and the tailpin replaced.

- While the Commission was unable to determine the cause of the bend in the tailpin, examination of the fatigue crack indicates that the bend was very likely present before the fracture occurred.

- It is very likely the alarm activated when the carriages parted.

- If KiwiRail’s Operating Rules included the procedures to be followed in a mechanical coupler failure, and the crew were trained in those procedures, it is likely that the hazards of returning the parted train to Christchurch would have been identified and mitigated.

Safety issues and remedial action Ngā take haumanu me ngā mahi whakatika

General

- Safety issues are an output from the Commission’s analysis. They may not always relate to factors directly contributing to the accident or incident. They typically describe a system problem that has the potential to adversely affect future transport safety.

- Safety issues may be addressed by safety actions taken by a participant. Otherwise the Commission may issue a recommendation to address the issue.

Safety issue 1: The maintenance and inspection of carriage-coupler connections was inadequate to identify existing faults of safety-critical components. This increased the risk of failure of the components during operation.

-

Following the incident, KiwiRail informed the Commission that it had taken the following safety action:

Maintenance programme for eye bolt type couplers: We are looking at an annual inspection on the eye bolt (tailpin) to coincide with the vehicle annual C-Check – details are still being worked through as it requires disassembly of the drawgear. It would only be carried out on the AKS/AKF class of cars.

Existing eye bolts replacement: All eyebolts have been replaced with new for all the AKS/AKF fleet in the South Island and the first consist of H2A SR carriages. Work on next H2A consist will begin at the start of October.

Clarification: new eye bolts of the existing design were used for this.

New material tensile review of the eye bolt: An Engineering Change Request is underway for this, currently in the detail design and FEA stage. AKF and AKS carriages are programmed for upgrade to Amsted solid shank couplers from May-July 2025. KiwiRail intends to introduce the new eye bolt design at the same time as this conversion is done. Clarification: this will be a stronger version of the same part incl. the nut. 4340 steel will be used for both. To be done concurrently with conversion to Amsted couplers. The bolt redesign may be a permanent or an interim improvement pending the following step, if implemented.

New design to fit the AK Class coupler system to the AKS/AKF fleet: Design review complete and shows this change is feasible. However, this is a longer-term project as it involves major underframe work to be carried out along with prototyping and type testing. This approach does also have risks of its own that must be considered. KiwiRail will need to determine which of the two designs (current design with strengthened eye bolt or AK-style yoke system) is the best permanent solution for these carriages Clarification: This is a much more involved redesign of the coupler system. Care must be taken to avoid over-strengthening the drawgear and in doing so shift the potential failure point to another, less desirable location in the carriage.

- The Commission welcomes the safety action to-date but until the above action is implemented the safety issue remains. Therefore the Commission has made a recommendation in Section 6 to address this issue.

Safety issue 2: The train’s alarm system (TMS) did not alert the crew that the train had parted. This meant the onboard crew continued with their duties unaware of the risk to themselves and passengers.

-

On 19 September 2024, KiwiRail informed the Commission that it had taken the following safety action regarding the TMS alarm:

An Engineering Change Request will be raised for potential adjustment to volume and duration, subject to consultation with operating staff. Note however that the purpose of the TMS alarm is to alert staff to a fault. It is not for passengers so would not by itself indicate to passengers that there was a hazardous situation in the vestibule area after a parting. It is also consist-wide and not specific to one location on the train.

- The Commission welcomes the safety action to-date but until the above action is implemented the safety issue remains. Therefore the Commission has made a recommendation in Section 6 to address this issue.

Safety issue 3: KiwiRail’s processes and procedures to respond to a train parting because of mechanical failure were inadequate and increased the risk of injury to rail personnel and damage to rail vehicles.

- No action has been taken to address this safety issue. Therefore, the Commission has made a recommendation in Section 6 to address this issue.

Other safety action

-

In addition to the safety actions noted above, KiwiRail informed the Commission that following the incident it has taken the following action:

Since the incident KiwiRail have removed a locomotive from the rear and front of the TranzAlpine when traveling between Otira and Arthur’s Pass.

KiwiRail is reviewing the maintenance inspection process for inspecting the tailpin component.

KiwiRail is reviewing upgrading the AKS coupler to an Amsted solid shank coupler and will fit the improved (4340 steel) tailpin.

KiwiRail is submitting a change request to change the volume and duration of the TMS alarm.

Recommendations Ngā tūtohutanga

General

- The Commission issues recommendations to address safety issues found in its investigations. Recommendations may be addressed to organisations or people and can relate to safety issues found within an organisation or within the wider transport system that have the potential to contribute to future transport accidents and incidents.

- In the interests of transport safety, it is important that recommendations are implemented without delay to help prevent similar accidents or incidents occurring in the future.

New recommendations

- On 26 March 2025, the Commission recommended that KiwiRail review and improve the maintenance and inspection of safety-critical components of the carriage-coupler system to ensure they remain safe to operate. [034/25]

-

On 16 April 2025, KiwiRail replied:

This recommendation is accepted. KiwiRail has completed design, manufacture, and trial installation of improved eye bolts. Improvements include material choice, reduction of stress raisers and thread root surface finish. Installation of new eye bolts on in-service carriages begins 28th April 2025. The eye bolts will then be removed for inspection annually.

- On 26 March 2025, the Commission recommended that KiwiRail review and improve the automatic carriage alarm system (TMS) to ensure it alerts the crew to faults. [035/25]

-

On 16 April 2025, KiwiRail replied:

This recommendation is accepted. KiwiRail has raised an Engineering Change Request to review the AKL TMS alarm, and this is now underway. The review considers alarm duration, alarm volume and ability of the system to distinguish between event types. The scheduled timeframe to complete the review and introduce improvements is the end of 2025.

- On 26 March 2025, the Commission recommended that KiwiRail include in its Operational Rules the processes and procedures to respond to a train parting because of a mechanical failure, to ensure the risk of injury to rail personnel and damage to rail vehicles is mitigated. [036/25]

-

On 16 April 2025, KiwiRail replied:

This recommendation is accepted. We will work on this with the Rules Committee to implement appropriate changes.

Key lessons Ngā akoranga matua

- Owners and operators of safety-critical equipment must have adequate processes in place to maintain that equipment to ensure its safe operation.

Data summary Whakarāpopoto raraunga

Details

Conduct of the Inquiry He tikanga rapunga

- On 18 December 2023, the NZTA notified the Commission of the occurrence. The Commission subsequently opened an inquiry under section 13(1) of the Transport Accident Investigation Commission Act 1990 and appointed an Investigator-in-Charge.

- Commission investigators attended the site on 19 December 2023 and conducted a site investigation.

- The Commission obtained records and information from sources that included:

- Quest Integrity NZL Limited on material composition and failure report

- locomotive engineer training and certification records

- Tranzlog data from the locomotive

- train control graphs

- train simulations

- modification specifications for the redesign of the AKS carriage

- carriage-coupler specifications

- KiwiRail’s train parting procedures.

- On 28 November 2024, the Commission approved a draft report for circulation to five interested parties for their comment.

- Three interested parties each provided detailed submissions and one interested party replied that they had no comment. The remaining interested party did not respond despite efforts to contact them. Any changes as a result of the submissions have been included in the final report.

- On 26 March 2025, the Commission approved the final report for publication.

Glossary Kuputaka

- Buff compression force

- The inward force applied to the carriage-coupler connection

- Carriage

- A rail vehicle that conveys passengers.

- Chassis

- The steel structure that supports the wheels and suspension systems and above carriage structure.

- Drawgear system

- The component that connects the carriage to the coupler

- Draft tensile force

- The outward force applied to the carriage-coupler connection

- Independent brake

- The locomotive’s brake system

- Full service break application

- The maximum train braking force that can be applied through the train’s air brake system

- Locomotive

- Self-propelled rail vehicle that provides motive power for a train

- Locomotive engineer

- Mainline train drivers are referred to by KiwiRail as locomotive engineers to reflect the required qualifications of the role.

- kN

- Kilonewtons

- Throttle position

- The locomotive’s power positions between idle and eight

- Part

- Loss of connection between two or more rail vehicles.

- Tranzlog

- The train’s ’black box’ data recorder.

- Spring pack

- The damping system that absorbs in-train forces to the carriage-coupler connections

Citations Ngā tohutoru

Totland, J. (2021). Design considerations for auditory alarms in the process industry: a systematic literature review. University of South-Eastern Norway, Faculty of Technology, Natural Sciences and Maritime Sciences.

Wickens, C.D., Helton, W.S., Hollands, J.G. & Banbury, S. (2021). Engineering psychology and human performance (Fifth edition). Routledge.

Williams, T., Esposito, T., Hu, S., Mahoney, D., & Paulson, K. (2014). Effects of varying audio frequencies on reaction time and muscular activity. Journal of Advanced Student Sciences.

Appendix 1. KiwiRail safety alert post incident

Appendix 2. KiwiRail Operation Rule 14.5 Graduated release brakes for platform stops

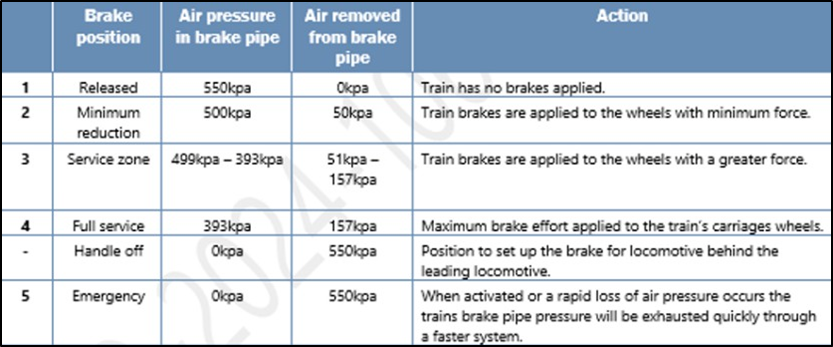

Appendix 3. Train’s air brake positions

Appendix 4. TranzAlpine Job Aid instruction for stopping at Arthur’s Pass station

Related Recommendations

On 26 March 2025, the Commission recommended that KiwiRail include in its Operational Rules the processes and procedures to respond to a train parting because of a mechanical failure, to ensure the risk of injury to rail personnel and damage to rail vehicles is mitigated.

On 26 March 2025, the Commission recommended that KiwiRail review and improve the automatic carriage alarm system (TMS) to ensure it alerts the crew to faults.

On 26 March 2025, the Commission recommended that KiwiRail review and improve the maintenance and inspection of safety-critical components of the carriage-coupler system to ensure they remain safe to operate.