A BK117 helicopter was transporting a power pole. Pilot at risk of distraction, didn’t recognise and respond promptly to unanticipated yaw (helicopter unexpectedly turning about its vertical axis). The pilot lost control and ditched in shallow water. Minor injuries for pilot, substantial damage to helicopter.

Executive summary Tuhinga whakarāpopoto

- On Tuesday 2 May 2017, a BK117 A-3 helicopter was being used to transport three 11-metre long hardwood power poles from a staging area on one side of the Pāuatahanui Arm of Porirua Harbour and place them in holes that had been prepared near the shoreline on the other side of the Arm.

- The first pole had been connected by a sling to the cargo hook beneath the helicopter. The helicopter lifted the pole from the staging area and was flying across the water when the pilot began to lose control of the helicopter. The pilot made an emergency ditching into shallow water.

- The pilot escaped from the partially submerged helicopter with minor injuries. The helicopter was substantially damaged.

- The Transport Accident Investigation Commission (Commission) found no mechanical issues with the helicopter that would have likely contributed to the accident.

- The Commission found that control of the helicopter was lost likely due to a phenomenon known as unanticipated right yaw. The Commission also found that operational pressure likely combined with other stressors to increase the risk of the pilot becoming distracted.

- The pilot did not undergo post-incident drug and alcohol testing as per the operator’s drug and alcohol policy, but the pilot did undergo a Police breath alcohol screening test immediately after the accident.

- There was no evidence to suggest that the pilot’s previously diagnosed medical condition or the medication prescribed was a factor in this accident. However, non-disclosure of the medical condition and prescribed medication to the Civil Aviation Authority was a serious concern for the Commission.

- The Commission found several significant anomalies in the maintenance records for the helicopter, which had been left unresolved at the time the Civil Aviation Authority issued it with a certificate of airworthiness.

- The helicopter had not undergone all the inspections and verification-of-maintenance tasks required before the Civil Aviation Authority issued the certificate of airworthiness.

- During the inquiry it was discovered that other aircraft owned and operated by the same company that imported the helicopter into New Zealand also had significant anomalies in their maintenance records.

- In its interim report on the accident, the Commission raised with the Civil Aviation Authority that the number and nature of maintenance anomalies involving aircraft operated by Helipro were a safety issue. The concern was that there could be historical or latent maintenance issues with some of Helipro’s other aircraft that had been on-sold and were then being operated on the New Zealand register by various other companies.

- The Civil Aviation Authority immediately issued a Continuing Airworthiness Notice to address that safety issue. It was subsequently withdrawn after no reports were received.

- In this report the Commission has identified a further safety issue, whereby the Civil Aviation Authority’s process for entering second-hand imported aircraft into the New Zealand regulatory system was not clearly defined; was not clearly understood by some staff; and did not have the checks in place to ensure it was followed.

- The Civil Aviation Authority subsequently arranged an independent review of the process for issuing a certificate of airworthiness, including the conformity inspection process for second-hand aircraft. However, the Commission believes further action needs to be taken. As a result, the Commission has made one recommendation to the Civil Aviation Authority to address that issue.

- Key lessons arising from the inquiry include:

- pilots can experience distraction during all phases of flight. Pilots must remain vigilant to ensure that their performance is not degraded by distraction when attending to various tasks necessary to the safe operation of an aircraft

- unanticipated yaw is a flight characteristic to which all types of single-rotor helicopter can be susceptible. Pilots need to remain cognisant of the conditions in which the phenomenon is likely to occur and the actions required for recovery

- the disclosure of medical conditions and prescribed medication to the Civil Aviation Authority ensures that their aeromedical significance can be determined. It does not automatically preclude a pilot from carrying out their duties, but does ensure a pilot can operate an aircraft safely

- it is essential that all maintenance and inspection tasks are conducted and properly recorded in accordance with applicable rules.

Factual information Pārongo pono

Narrative

- On 2 May 2017, a Messerschmitt-Bölkow-Blohm GmbH BK117 A-3 helicopter (the helicopter), was being used to transport three 11-metre long hardwood power poles from an area of open land (the staging area) near the shore on one side of the Pāuatahanui Arm of Porirua Harbour and place them in holes that had been prepared near the shoreline on the other side of the Arm (refer to Figure 3).

- The weather in the Porirua area at the time of the accident was reported by MetService (New Zealand’s sole certificated aviation weather forecast provider: http://www.metservice.com/national/home) as partly cloudy, with a northerly wind of eight knots (15 kilometres per hour [km/h]), gusting to 20 knots (37 km/h), and good visibility. The temperature was 13.5° Celsius. Witnesses in the area described similar conditions.

- On the morning of the accident, the pilot arrived at the staging area by road and briefed staff from the electricity network on the lifting operation. The pilot had previously given a hand-held portable air-to-ground radio to the electricity network staff at the worksite across the harbour to communicate with the pilot while placing the poles in the holes. There was an additional hand-held radio for staff at the staging area to communicate with the helicopter during the operation.

-

The pilot prepared the first lift by joining two slings together to make a 20-metre lifting line, which was then attached to the first pole lying on the ground. The operator’s chief pilot was also at the staging area conducting an internal audit of the operation.

- Meanwhile another pilot (the staff pilot) was ferrying the helicopter from the operator’s Wellington base to the staging area.

- Following a brief handover of the helicopter from the staff pilot and the removal of the right-hand door, the pilot took control of the helicopter and lifted into a hover while a member of the ground crew attached the lifting line to the helicopter’s cargo hook. The helicopter then lifted the pole, and global positioning system (GPS) data showed that the helicopter climbed vertically to approximately 120 feet (37 metres). The helicopter repositioned, turned and transitioned forward to a speed of about 40 knots (74 km/h), climbing to 230 feet (71 metres) above the water. It flew in a southwesterly direction towards the worksite (see Figure 3).

- The operator’s chief pilot at the staging area overheard, on the portable radio, the pilot make a call to the staff at the worksite as the helicopter made the short trip across the water. The pilot did not get a response. The staff at the worksite stated that they did not receive the call.

- After the short transit across the water, the pilot began to slow the helicopter as it was nearing the worksite. The pilot later recalled changing radio channels to make contact with staff at the worksite, when what the pilot described as “a significant medium-frequency airframe vibration” occurred, which then “amplified with pronounced oscillation”, followed by a “sudden rotation of the helicopter to the right”.

- A witness at the staging area stated they could hear on the radio the pilot attempting to call staff at the worksite. The witness described seeing the helicopter's nose pitching up and the helicopter starting to rotate immediately after the pilot made the call.

- The pilot reported that they abruptly lowered the collective lever, which had the effect of slowing the rotation, but caused the helicopter to descend more quickly than the pilot expected. The pilot then raised the collective lever again, but the helicopter rolled to the right, pitched nose down and struck the water. The pilot did not recall jettisoning the load from the helicopter's hook, although one witness saw the pole fall after the helicopter started rotating.

- The helicopter struck the water right-side low and suffered substantial damage to the main rotor blades, engines and engine drive shafts. The fuselage remained relatively intact.

- The helicopter came to rest on its right side in shallow water. The pilot was seated on the right side, wearing a three-point seat harness, and had to perform an underwater evacuation for which they had previously received training. The pilot suffered minor injuries.

Personnel information

- The pilot held commercial pilot licences for helicopters and aeroplanes. The pilot’s total flying experience was approximately 8,300 hours, with approximately 7,000 of those hours on various helicopter types. The pilot held a Category B flight instructor rating and a multi-engine instructor rating, for which a renewal check was conducted on 13 December 2016.

- The operator’s chief pilot conducted the pilot’s last flight crew competency check on 1 November 2016.

- At the time of the accident, the pilot held a current class one medical certificate with an endorsement for spectacles to be available. On 5 May 2017 (three days after the accident), the Civil Aviation Authority (CAA) withdrew the certificate. The notice of withdrawal stated that ‘records at CAA indicate possible medical circumstances that may jeopardise flight safety’.

- The pilot had been prescribed medication to treat a medical condition. The medication and condition were of aeromedical significance, but neither was disclosed to the CAA, and according to the pilot, the prescription medication had not been taken. The pilot had seen a different general practitioner (GP) from their declared GP for this medical condition.

- There was nothing in the pilot’s medical records for the five months prior to the accident to indicate that the pilot had consulted their declared GP. Ministry of Health records for this period showed there had been no prescriptions dispensed to the pilot since December 2016.

- The operator of the helicopter had a drug and alcohol policy that required a pilot to be tested after an accident. The pilot underwent a Police alcohol screening test after the accident, which returned a negative result, but did not undergo a drug test as required by the company policy. A witness who had been located at the staging area, who knew the pilot, said that the pilot looked physically tired on the day of the accident.

Organisation information

- On 26 March 2014, the helicopter was first registered in New Zealand to another company trading as Helipro.

- Helipro Aviation Support Limited (Helipro Maintenance) was a part of the Helipro business. Helipro Maintenance was a maintenance provider certificated under Civil Aviation Rules (CAR) Part 145 (the holder of a CAR Part 145 certificate is authorised by the CAA to perform maintenance in accordance with the specifications in their exposition and the general maintenance rules in CAR Part 43. Without the certificate, maintenance could be performed only in accordance with CAR Part 43, which limited the scope of the maintenance that could be performed) until July 2014.

- Helipro Maintenance staff prepared the helicopter for the CAA airworthiness certificate inspection in August 2014. The helicopter was then maintained under CAR Part 43 General Maintenance Rules as it was not being used for air transport operations.

- The pilot was the chief pilot and a director of Helipro until November 2014. Helipro had been placed into receivership in October 2014.

- On 7 November 2014, Precision Helicopters Limited (Precision Helicopters) became the registered operator of the helicopter. It was being operated under that company’s air operator certificate at the time of the accident. The helicopter was leased to Heliforce under a business arrangement whereby Heliforce employed the pilots who flew the helicopter and arranged the work contracts with clients.

- The helicopter was added to the Precision Helicopters ‘operational specification’ (the conditions imposed by the Director of the CAA on the air operator certificate, including any authorisations, limitations and procedures that form part of the certificate). The helicopter was then operated from Wellington Airport, with Precision Helicopters controlling the maintenance, training and quality systems of the operation.

- Precision Helicopters was authorised under CAR Part 119 to perform air operations and associated activities in accordance with CAR Parts 135 and 133, as detailed in the operations specification and the organisation’s exposition.

- The lifting task on 2 May 2017 was a permitted operation for Precision Helicopters. The pilot was employed by Heliforce, and held a category A pilot status with the operator. This meant the pilot could have, and was given, sole charge of the lifting activities. However, as the operator, Precision Helicopters had responsibility for ensuring it was conducted in accordance with its policies and procedures.

Aircraft information

- The BK117 A-3 helicopter is powered by two turbo-shaft engines. Power from the engines is transmitted to the main rotor transmission through drive shafts with flexible couplings. Each engine drive shaft is connected to a freewheel clutch within the main rotor gearbox to enable single engine operation or to facilitate autorotation. The helicopter has four glass-fibre-reinforced main rotor blades connected to a titanium rigid rotor head. The BK117 has an anti-clockwise rotating main rotor when viewed from above.

- The tail rotor comprises two semi-rigid, glass-fibre-reinforced-plastic tail rotor blades with a central flapping hinge. The tail rotor gearbox is fitted to the top of the vertical fin, with an intermediate gearbox at the base of the fin. Attached to the horizontal stabiliser, either side of the vertical fin, are vertical stabilisers.

- The accident helicopter had a ‘yaw stability augmentation system’, which applied limited control inputs to the tail rotor through an electro-hydraulic servo. The control switch for this system is located in the cockpit. The system was normally switched on, as it was in this case.

- The maximum allowable all-up weight for the helicopter was 3,200 kilograms (kg). A flight manual supplement for the hook assembly specified that the underslung load limit on the hook assembly was 900 kg, although this was later determined to be erroneous at the time of the accident and the correct load limit was 1,200 kg.

- The helicopter was manufactured in Germany in 1985 by Messerschmitt-Bölkow-Blohm GmbH (later part of Airbus Helicopters). It was imported into New Zealand from the United States in January 2014, having accrued a total time in service of 11,123 hours.

- A second BK117 helicopter, with serial number 7124 (helicopter B), was imported from the United States at the same time. Parts from helicopter B were later installed on the accident helicopter.

- For an aircraft to be eligible for an airworthiness certificate in New Zealand, it must have a statement of conformity. Neither helicopter came into New Zealand with a United States Federal Aviation Administration (FAA) export certificate of airworthiness. Therefore, in order for an airworthiness certificate to be issued, the CAA required an inspection of the helicopter and its associated documentation by its staff, as well as a review of airworthiness by an ‘authorised person’ (a person who is the holder of a ‘certificate of an inspection authorisation’ issued by the CAA) in order to be satisfied that the helicopter conformed to its type certificate (a document issued by the State of Design to define the design of a product and to certify that the manufacturer has demonstrated its compliance with regulatory requirements). More information on these aspects is included in section 4.6 below. On 21 August 2014, the CAA issued the helicopter with an airworthiness certificate (helicopter B was not issued with a New Zealand airworthiness certificate).

- The helicopter had flown a total of about 11,512 hours at the time of the accident. The last annual review of airworthiness had been completed on 24 October 2016. The last scheduled maintenance had been a 50-hour airframe inspection carried out on 18 November 2016.

Wreckage and impact information

- Moderate damage to the right-hand underside of the helicopter (see Figure 4) indicated that the helicopter had a right bank and level pitch attitude when it struck the water.

- There was a slight twist in the tail boom structure. All four main rotor blades had been destroyed from striking the water while under power.

- The forward left main rotor transmission mount had buckled under compression loading from the vertical component of the impact forces.

- The power output assemblies of both engines were damaged by overload forces applied during the sudden stoppage of the main rotor.

- The tail rotor blades and associated drive train appeared to be undamaged and remained connected to the main rotor transmission.

- The flight control system was undamaged, with no defects evident.

- The left side of the vertical fin had failed and separated and the right-hand side was buckled (see Figure 5).

- The vertical fin spar was found to have a diagonal crack extending through it (see Figure 6).

Tests and research

- A licensed aircraft maintenance engineer, rated on the BK117, and a technical adviser from Airbus helicopters found no defects in the tail rotor assembly or drive train that could have caused a loss of tail rotor control or that could have contributed to the failure of the vertical fin structure.

- Other known BK117 accidents were considered. In 1997 a BK-117-B2 struck terrain and was investigated by the National Transportation Safety Board of the United States (NTSB). The investigation found that the tail fin had failed due to fatigue. The use of blind rivets had increased the tail fin structure’s susceptibility to fatigue. In 2006 a fatigue crack was identified in the vertical fin of a BK-117. The manufacturer subsequently issued an Alert Service Bulletin to helicopter operators to address the issue.

- Solid rivets were fitted to the accident helicopter, not the hollow rivets that had contributed to the fatigue-related structural failure in 1997.

-

An expert metallurgist engaged by the Commission examined the vertical fin and determined that the crack in the spar was the result of structural overload during the forced landing. The Defence Technology Agency (DTA) (the main provider of research, science and technology support to the New Zealand Defence Force and the Ministry of Defence) also carried out testing. They visually inspected the vertical fin and then inspected six possible crack initiation sites using scanning electron microscopy (SEM) (the use of a scanning electron microscope, which is a type of electron microscope that produces images of a sample by scanning the surface with a focused beam of electrons). The results of the DTA inspection were consistent with the results of the previous expert metallurgist examination. The DTA concluded:

DTA inspection of the fracture faces of samples … are consistent with overload fracture upon impact. There was no evidence of fatigue cracking, brittle fracture or pre-existing defects.

Analysis Tātaritanga

Introduction

- During a routine flight to transport a hardwood power pole across the Pāuatahanui Arm of Porirua Harbour, the directional control of the helicopter was lost and the helicopter subsequently struck the water. This section discusses the reasons for the loss of directional control and other factors that likely contributed to the accident.

- The following analysis also discusses two safety issues; neither was likely to have contributed to this accident:

- the CAA’s process for entering second-hand imported aircraft into the New Zealand regulatory system was not clearly defined; was not clearly understood by some staff; and did not have checks in place to ensure it was followed

- the number and nature of the maintenance anomalies involving the accident helicopter and the three other helicopters operated by Helipro are an indication that there could be historical or latent maintenance issues with some of its other aircraft that have been on-sold and are currently being operated on the New Zealand register by various other companies.

What happened

- Data recovered from the GPS showed that the helicopter lifted off at the staging area around 1135. While it transited the harbour the GPS recorded a maximum groundspeed of 38 knots (70 km/h). It also showed that the helicopter was slowing down shortly before the accident, with the last reliable data point indicating a groundspeed of 35 knots (65 km/h). The helicopter’s groundspeed likely continued to decrease; however limitations in how the GPS stored data resulted in it not being saved to the non-volatile memory (the GPS recorded a final data point that showed a groundspeed of about 12.5 knots (23 km/h), but it was not considered reliable).

- The pilot recalled that around this time a significant medium-frequency airframe vibration occurred, which amplified with pronounced oscillation, followed by a sudden rotation of the helicopter to the right. The pilot also recalled applying the appropriate inputs for a tail rotor failure, which involved lowering the collective lever.

- The chief pilot, who was about one kilometre away at the staging area, reported seeing the helicopter flaring abruptly, “like a quick stop”, then beginning to rotate and hearing a noise that the chief pilot described as a “crack”. The investigation was unable to determine the source of this reported noise, but it may have been the underslung load entering the water.

- The recollections of the pilot and chief pilot of a sudden rotation of the helicopter are consistent with a loss of directional control. A conventional helicopter such as a BK117 may lose directional control at low airspeeds for one of two reasons, either a mechanical or structural failure, or an aerodynamic flight characteristic known as unanticipated right yaw. Similarly, airframe vibration can result from various mechanical and aerodynamic sources, including entering low airspeed, or a mechanical or structural failure.

-

In 1995, Advisory Circular 90-95 ‘Unanticipated right yaw in helicopters’ was issued by the FAA and identified the following:

[unanticipated right yaw] has been identified as a contributing factor in several helicopter accidents involving loss of control. Flight operations at low altitude and low airspeed in which the pilot is distracted from the dynamic conditions affecting control of the helicopter are particularly susceptible to this phenomena.

Mechanical and structural failures

- As part of the investigation, a licensed aircraft maintenance engineer, rated on the BK117, and a technical adviser from Airbus Helicopters found that continuity existed throughout the tail rotor system and no defects were identified that could have caused a loss of tail rotor control. Some wear was observed in the spherical bearings of the tail rotor pitch links, but this was within allowable limits. It was unlikely that the tail rotor system contributed to the accident.

- The damage to the vertical fin was examined by expert metallurgists using visual and SEM techniques. They determined that the crack in its spar was the result of structural overload and that there were no pre-existing cracks in the vertical fin. An excerpt from the SEM metallurgy report is at Appendix 1

-

The investigation considered the possibility of this structural overload occurring in flight. However, the metallurgical examination noted the following with regard to the internal tail fin inspection:

the tail rotor was not rotating at any significant speed when the vertical fin failed.

-

The DTA metallurgical examination of internal damage to the tail fin noted:

The impact site shows no evidence of scoring which would be associated with tail shaft rotation.

- An in-flight failure of the tail fin was therefore considered unlikely due to the lack of rotational damage within the internal tail fin structure. The lack of rotational damage was consistent with the main rotor blades striking the water first and dissipating the energy in the rotor system, resulting in the driveline failure prior to the tail fin damage occurring. The right bank attitude during the impact would have also resulted in the tail fin damage observed in Figure 5 and the slight twist in the tail boom structure. It was therefore likely that the tail fin failed in overload when the helicopter struck the water.

- No other significant damage was identified in the tail rotor system or associated airframe. It was therefore unlikely that a mechanical failure of the tail rotor system or associated airframe contributed to the accident and that the vibration felt by the pilot was the result of an aerodynamic phenomenon.

Unanticipated right yaw

-

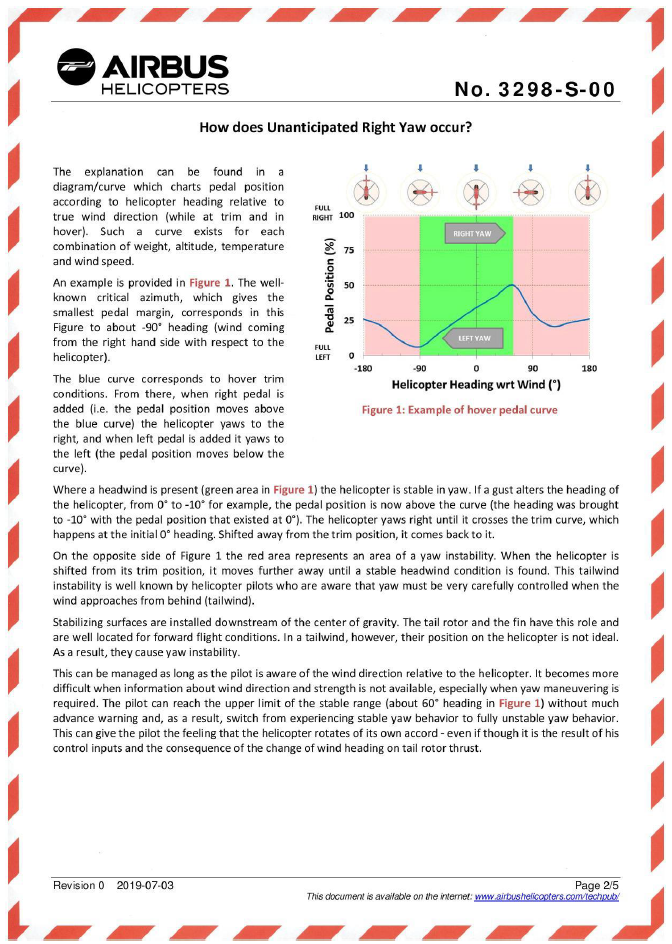

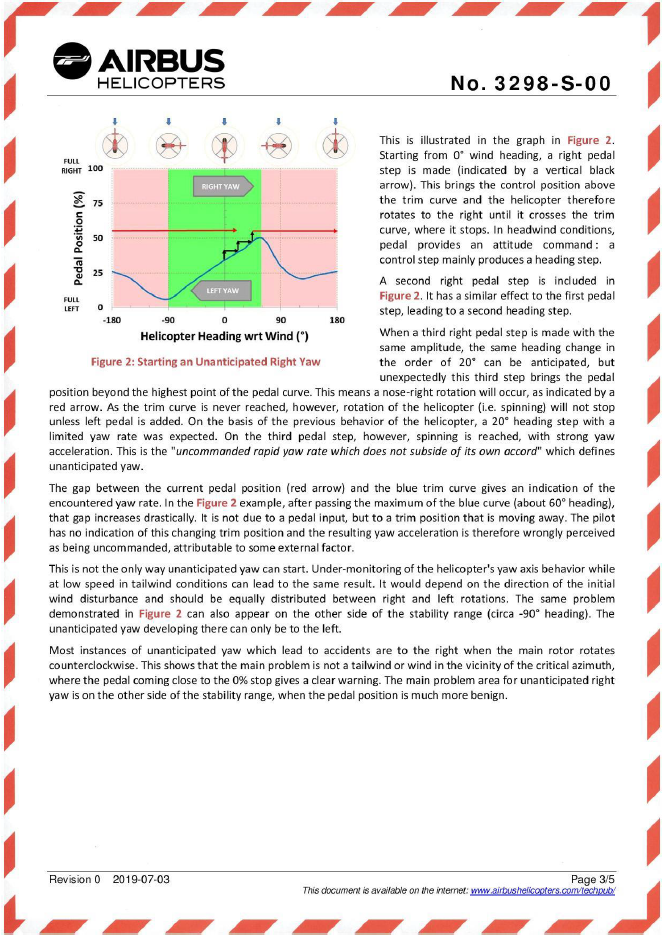

In July 2019 Airbus Helicopters issued Safety Information Notice 3298-S-00 (Appendix 2: Airbus Helicopters Safety Information Notice No. 3298-S-0), which described unanticipated right yaw as being an “uncommanded rapid yaw rate which does not subside of its own accord”. The Safety Information Notice further elaborated;

Unanticipated yaw is a flight characteristic to which all types of single rotor helicopter can be susceptible at low speed, dependent usually on the direction and strength of the wind relative to the helicopter.

Where this type of unanticipated yaw situation is encountered, it may be rapid and most often will be in the opposite direction of the rotation of the main rotor blades (i.e. right yaw where the blades rotate counter clockwise). Swift corrective action is needed in response otherwise loss of control and possible accident may result.

However, use of the rudder pedal in the first instance may not cause the yaw to immediately subside, thus causing the pilot to make inadequate use of the pedal to correct the situation because he suspects that it is ineffective when, in fact, thrust capability of the tail rotor available to him remains undiminished.

-

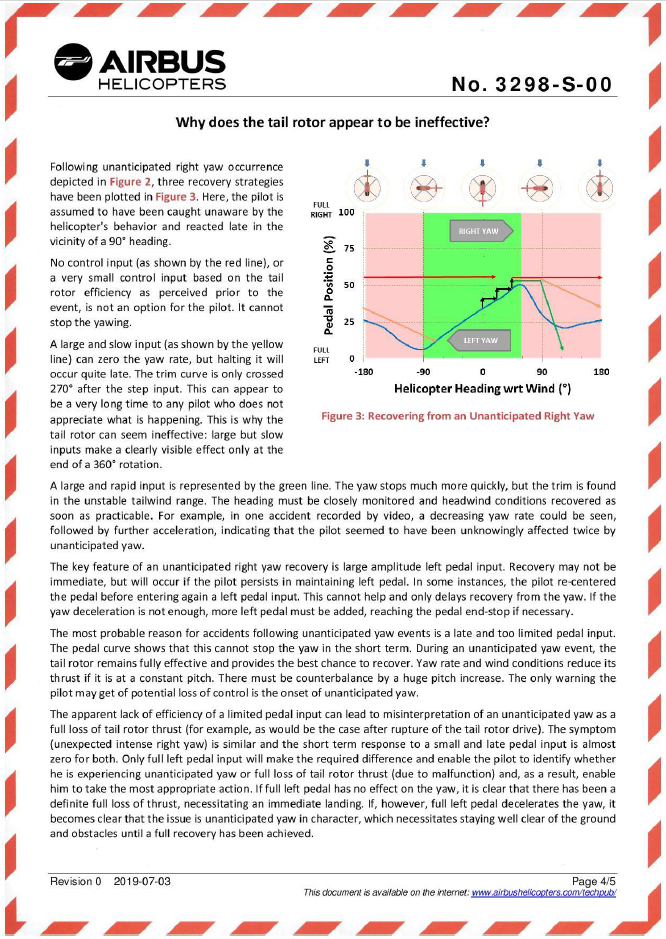

The Safety Information Notice also provided a detailed description of recovery from unanticipated right yaw and why initial corrective tail rotor inputs may appear to be ineffective to the pilot, leading them to believe that there has been a mechanical failure:

The key feature of an unanticipated right yaw recovery is large amplitude left pedal input. Recovery may not be immediate, but will occur if the pilot persists in maintaining left pedal. In some instances, the pilot re-centered the pedal before entering again a left pedal input. This cannot help and only delays recovery from the yaw. If the yaw deceleration is not enough, more left pedal must be added, reaching the pedal end-stop if necessary.

The most probable reason for accidents following unanticipated yaw events is a late and too limited pedal input. During an unanticipated yaw event, the tail rotor remains fully effective and provides the best chance to recover. Yaw rate and wind conditions reduce its thrust if it is at a constant pitch. There must be counterbalance by a huge pitch increase. The only warning the pilot may get of potential loss of control is the onset of unanticipated yaw.

The apparent lack of efficiency of a limited pedal input can lead to misinterpretation of an unanticipated yaw as a full loss of tail rotor thrust

Only full left pedal input will make the required difference and enable the pilot to identify whether he is experiencing unanticipated yaw or full loss of tail rotor thrust (due to malfunction).

-

Additionally the Safety Information Notice provided information relating to the recovery from unanticipated yaw:

If unanticipated yaw occurs, react immediately and with large amplitude opposite pedal input. Be ready to use full pedal, if necessary. Do not limit yourself to what you feel sufficient, your feeling can be wrong. Never bring the pedal back to neutral before the yaw is stopped.

- These documents noted relative wind strength and direction, low airspeed, low altitude, a high power setting, distraction and misinterpretation as factors that can contribute to unanticipated right yaw occurring and result in an accident.

- The nearest certified weather station was at Porirua, approximately six kilometres from the accident site. At 1200 it recorded a wind speed of 8 knots (15 km/h), gusting 20 knots (37 km/h), and a wind direction of 020° (northerly). The differing local topography between the accident site and this weather station resulted in the investigation placing less weight on the weather station’s recorded data.

- The pilot and ground crew reported a westerly wind at the staging area approximately one kilometre from the accident site. Photographs taken shortly after the accident indicated a northerly wind on the water at the accident site. This variation was likely due to the complex topography in the surrounding area. While there is no direct evidence of the wind at the location of the accident, it was likely to have varied depending on the location relative to the topography in the area.

- The last GPS data point showed that the helicopter was at a low altitude of 210 feet (71 metres), with a heading of 240° true, and a 35-knot groundspeed that was decreasing. The decreasing groundspeed showed that the helicopter was slowing down shortly before the accident and that any adverse wind would have likely placed the helicopter at a low airspeed.

- The helicopter’s power setting was related to the airspeed and weight. The pilot had not obtained an accurate weight of the hardwood power pole prior to the accident flight. After the accident, the submerged pole was recovered and the electricity network company weighed the pole two weeks after the accident, after it had allowed it to dry. The measured weight of the pole at that time was 959 kg. This weight, along with the fuel and other equipment on the helicopter, resulted in the helicopter having a high gross weight. This high gross weight, combined with the slowing airspeed, would have likely required a high power setting at the time of the accident.

- At the time of the accident the pilot was also attempting to communicate with ground crew. Although this is a routine procedure when operating an aircraft, on this occasion the pilot did not receive a response from the ground crew when making this attempt. This resulted in the pilot being focused on using the radio system at the time of directional control loss. The chief pilot also recalled hearing the pilot attempt to contact ground crew at the time of the accident. The relationship between the radio call, the pilot changing channel and the loss of directional control was shown by the loss of control occurring almost immediately after the radio call was heard.

- A 1998 NASA (National Aeronautics and Space Administration) publication (NASA Air Safety Reporting System Directline, Issue No. 10 – https://asrs.arc.nasa.gov/docs/dl/DL10.pdf) examined 107 reports from the United States Air Safety Reporting System on incidents involving distraction. 68 of these reports identified communication as a source of distraction. The NASA publication further identified that in 69% of distraction-related incidents, pilots failed to monitor the current status of the aircraft. This shows a clear link between the effects of distraction associated with communication and its effect on monitoring. It was therefore likely that the communication difficulties experienced by the pilot were a source of distraction.

- Over several interviews, the pilot stated that they thought the accident was due to a failure of the tail fin. Their control inputs were based on tail rotor failure. A misinterpretation of unanticipated yaw as a tail rotor failure was identified in both Advisory Circular 90-95 and Airbus’s Safety Information Notice as a factor that could contribute to unanticipated yaw resulting in an accident.

- In the absence of any mechanical or structural failure with the helicopter prior to its hitting the water, and in conjunction with the factors present at the time of the accident that could contribute to unanticipated right yaw occurring, the investigation found it was likely that the loss of directional control was the result of unanticipated right yaw.

Human factors

- The pilot reported that there was some urgency to place the poles before the incoming tide filled the holes that had been dug by an excavator near the shoreline earlier in the morning. Staff at the worksite were pumping water from the first hole in preparation for placing the pole and back-filling with cement. The incoming tide was the factor giving urgency to the operation. The pilot reported that they had not perceived this urgency as a source of pressure and the investigation did not identify any pressure placed on the pilot by either the operator or the electricity network company to complete the task at this time.

- The chief pilot commented that the pilot appeared rushed during the handover from the staff pilot. Prior to that the pilot had made three phone calls to expedite the arrival of the helicopter at the staging point. The GPS data indicated that the helicopter was at the staging area for about three minutes from the time between the staff pilot landing the helicopter at the staging area and the pilot assuming control and lifting the helicopter.

- In addition, the helicopter arrived at the staging area with about 20 kg of approved lifting slings on board from the operator’s Wellington base. The pilot submitted that the lifting slings were not intended to be on board the helicopter at the time of the accident, but did not check the rear of the cabin and assumed they had been removed. The pilot in command was responsible for the safety of flight and ensuring that the cargo on board the helicopter was as expected and properly secured. Taking more time to ensure a good handover between pilots would likely have ensured that the pilot was aware of any additional load carried in the helicopter.

- The generic ‘IMSAFE’ (https://www.aviation.govt.nz/assets/publications/posters/Are_U_fit_2fly_Retro.pdf) checklist identified several checks with which a single pilot could determine their physical and mental readiness for flying. One such item was stress. Stress may cause concentration and performance problems. After the accident the chief pilot emailed the pilot about this issue.

-

A CAA Vector publication (Vector – Pointing to a Safer Aviation, Issue 8, 1998) also identified the impacts of stress:

Failure to manage stress often leads to eroded judgment [sic], decreased performance, inattention, loss of vigilance and preoccupation. A pilot suffering from stress tends to forget or skip procedural steps, accept lower performance standards and exhibit a tendency toward spatial disorientation and misperceptions. These misperceptions may result in misreading maps, charts and checklists, misjudgement of distance and altitude and loss of time perception.

- While the pilot indicated that they did not perceive any undue pressure at the time, the pilot’s actions and events on the day suggest that there was likely operational pressure, which was affecting the pilot’s level of stress. This stress likely increased the risk of the pilot becoming distracted.

Medical factors

- The pilot was diagnosed with a medical condition in 2016 that required disclosure to the CAA. In addition to this diagnosis, the pilot was prescribed medication that also needed to be disclosed to the CAA. This was required to ensure that their aeromedical significance was properly assessed. Neither the diagnosis nor the medication was disclosed to the CAA. The pilot reported that they had not taken the medication, and the pilot’s medical records for the previous five months did not indicate that any symptoms of the diagnosed condition were present at the time of the accident. The pilot submitted a specialist medical report in which the physician concluded that they would not have made the same diagnosis as had been made in 2016.

-

There was no evidence to suggest that the identified medical condition was present at the time of, or contributed to the accident. However, it was of concern that the pilot had been diagnosed with a medical condition and received prescription medicine and that these had not been disclosed to the CAA. The Commission has raised this safety issue in a previous report (Addendum to Final Report, Aviation inquiry AO-2015-002, Mast bump and in-flight break-up, Robinson R44, ZK-IPY Lochy River, near Queenstown, 19 February 2015), in which it commented that:

there is the potential for applicants for medical certificates to attempt to circumvent the medical assessment process by inaccurately representing their state of health through the misreporting of their treatment, including undisclosed medication and possible multiple GPs and other health professionals. This risk is shared by other transport modes that require a person to hold a medical certificate or make a declaration on their health status. A national health database would provide one means of addressing this risk.

- To address this safety issue, the Commission previously recommended that the Ministry of Health consider adding the following functions to the National Electronic Health Record database under development:

- that a person’s occupation be added to the record to allow monitoring of individuals who hold a transport-related document that requires a periodic medical check, and who have potentially adverse health conditions or medications, so that the appropriate authority can be alerted to possible public safety risks

- that there be a mechanism to draw the attention of all health practitioners to their obligation to notify the appropriate transport authority where a person or patient has a health condition or need for medication that could pose a threat to public safety in that individual’s occupation. [022/17]

- The Commission also recommended that the Director of the CAA review the medical application process to ensure:

- it promotes a positive reporting culture for applicants

- it is more robust in identifying potential serious health issues that may interfere with the safe exercise of the privileges to which the applicant’s medical certificate relates

- the system makes it standard procedure for medical examiners to consult with general practitioners when assessing applications for medical certificates. [021/17]

- These recommendations remained open awaiting full implementation at the time of publishing this report.

Helicopter airworthinessand maintenance

Safety issue: The CAA’s process for entering second-hand imported aircraft into the New Zealand regulatory system was not clearly defined; was not clearly understood by some staff; and did not have checks in-place to ensure it was followed.

Introduction

- The date when a helicopter is imported into New Zealand is the point when it enters the New Zealand regulatory system. It is important that the proper procedures are followed, particularly when importing second-hand helicopters. Any anomalies that are not identified at that point can stay with the helicopter for some time and present a risk to safe operation.

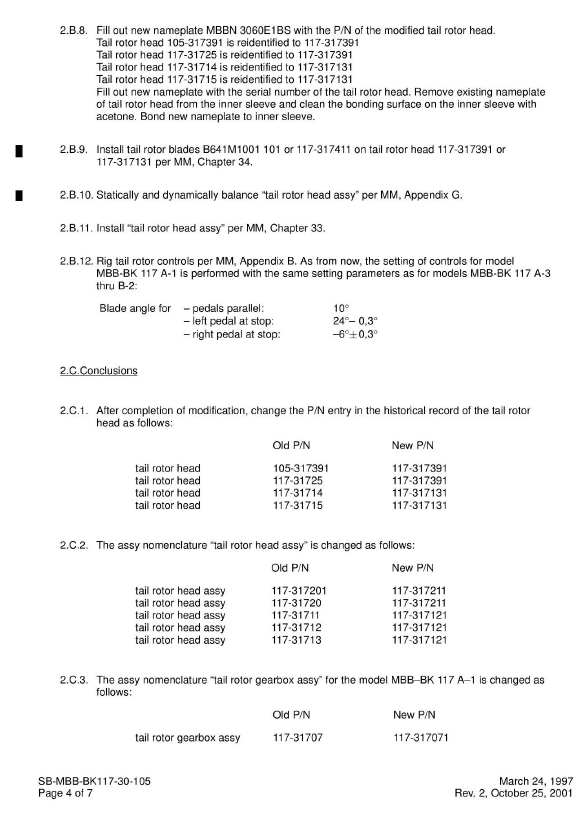

The published process for the issue of an airworthiness certificate

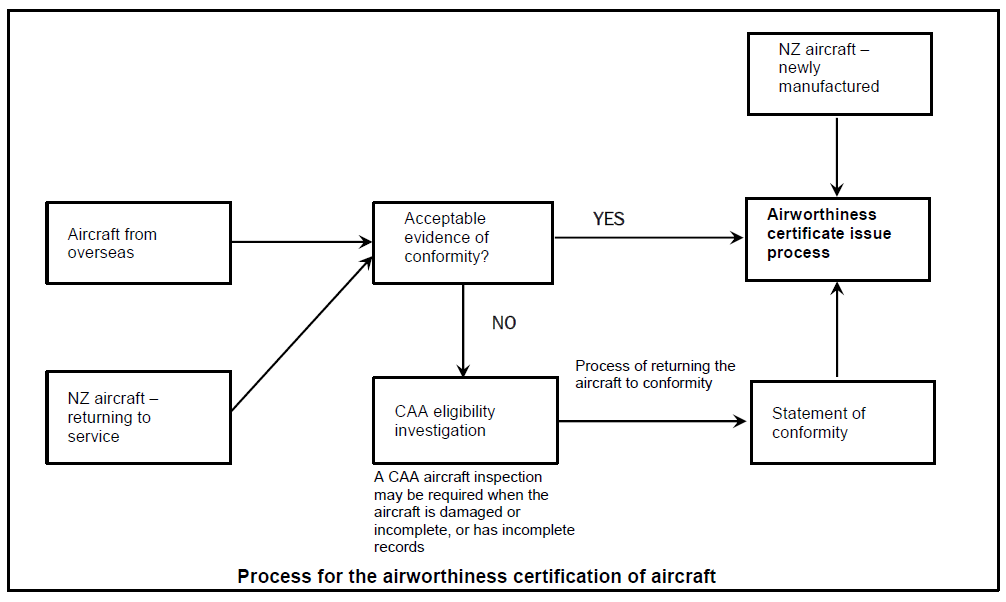

- Information about the process for issuing airworthiness certificates was published in Advisory Circular AC 21-2 Product Certification – Airworthiness Certificates in the Standard and Restricted Categories. The Advisory Circular (an Advisory Circular is guidance, issued by the CAA, pertaining to compliance with the Civil Aviation Rules) also included a flowchart showing the process (Appendix 5). CAA policies and procedures (ACU – 3.07 Issue of Airworthiness Certificates – Standard and Restricted Category) also outlined the process.

- According to the Advisory Circular, to be eligible for the issue of an airworthiness certificate the applicant must provide a statement of conformity issued at the completion of any work required to return that aircraft to conformity. The Advisory Circular outlined various documents or processes that would be accepted by the CAA as evidence of conformity.

- The Advisory Circular also stated that where the aircraft does not have an acceptable statement of conformity the CAA would undertake an ‘eligibility investigation’.

- An eligibility investigation is described in the Advisory Circular as a process that will inform the applicant of whether the information they provided about the [helicopter] will support the eventual issue of an airworthiness certificate, and it would enable the CAA to determine:

- why a conformity certificate (provided for by a statement of conformity in an export, or recent domestic, airworthiness certificate) was not reasonably obtainable [beforehand]

- the operating and maintenance history of an aircraft

- the origin and history of all lifed components

- the build or modification status of the aircraft

- the nature of any major repairs or reconstruction

- any deviations from the type design, and identify the method of returning to the type design

- who is suitable for issuing a certificate of conformity at the end of the process.

- The Advisory Circular noted that a physical inspection of the aircraft may also be conducted.

The process followed for the helicopter

- As shown in a letter sent to the operator, the CAA outlined that a review of airworthiness provided by the applicant would be acceptable as the statement of conformity for the helicopter (as shown in its letter to Helipro).

- A review of airworthiness was intended to prove that the helicopter had a level of airworthiness equivalent to that which would have been provided by an export certificate of airworthiness, had one been issued. The CAA also intended the review of airworthiness to provide compliance with CAR 91.615, which prescribed that an aircraft must not be operated without a review of airworthiness having been completed within the previous 12 months.

- A review of airworthiness does involve a check of conformity. However, it does not provide the prescribed statement of conformity required in order to issue a certificate of airworthiness. Neither the Civil Aviation Rules nor the Advisory Circular referred to using a review of airworthiness as a means for obtaining a statement of conformity. Nevertheless, that was what the CAA allowed.

- Having elected to accept a review of airworthiness, there was a need to establish who was eligible to conduct the review. That would normally be established as part of the eligibility investigation. However, the CAA did not conduct an eligibility investigation so it was never established or agreed with Helipro whether the person who might conduct the review of airworthiness was eligible, and could issue a statement of conformity.

- The Advisory Circular stated that a ‘holder of an Inspection Authorisation issued under Part 66 who is rated on the aircraft type will be acceptable to issue a statement of conformity for an aircraft found during the eligibility investigation to be complete, airworthy, and accompanied by a full maintenance history’. However, as mentioned above, an eligibility investigation was not conducted and the maintenance history was not complete, which is discussed in the following section.

- Notwithstanding that an eligibility investigation was not conducted, the CAA assumed that Helipro had staff with the necessary Inspection Authority to conduct the review, but it did not. Helipro did not have staff who both were rated on the helicopter type and held an Inspection Authorisation. Maintenance documents recovered from Helipro maintenance referred to the need for a review of airworthiness to be conducted for the helicopter, but none was ever recorded as having been done.

- The CAA performed an inspection of the helicopter on 21 August 2014. The airworthiness certificate inspection checklist used by the CAA referred to a [review of Airworthiness] Type Conformity as an ‘outstanding item’.

- None of the records held by the CAA and Helipro referred to the required review having ever been conducted. Therefore, it is almost certain that one was not conducted either before or after CAA issued the certificate of airworthiness for the helicopter.

- The ‘airworthiness certificate inspection checklist’ used by the CAA for the issue of the helicopter’s airworthiness certificate contained the following items under the heading ‘Rule 21.191(1),(2) Conformity to Type Design – Foreign Authority Documents’:

- ‘Export’ [certificate of airworthiness]. This had been ticked ‘no’, confirming the helicopter had no Export Certificate of Airworthiness.

- ‘Domestic’ [certificate of airworthiness]. This had been ticked ‘no’, confirming the helicopter had no current United States FAA domestic airworthiness certificate.

- ‘Eligibility Investigation required’ had been ticked ‘no’, contrary to the information given in the Advisory Circular that one would be required.

- ‘Conformity Inspection Report supplied’ had been ticked ‘no’, meaning the application did not have a separate conformity inspection report.

- ‘Details or file reference’ had the note ‘TAR (Type Acceptance Report (TAR) – A report produced by the CAA that details the basis on which New Zealand Type Acceptance has been granted) 7/21B/10 + [review of airworthiness]’. This referred to the CAA Type Acceptance Report number for the BK117, and confirmed that a review of airworthiness was required.

- On the final page of the checklist, under the heading ‘Outstanding Items’, ‘RA-Type Conformity’ (both of the abbreviations RA and ARA refer to a review of airworthiness. This is an inspection conducted by a delegated person holding an inspection authorisation (IA) issued under CAR Part 66 to check that the aircraft conforms to the applicable type certificate. The term RA was added in October 2017 when an optional biannual, rather than annual, review of airworthiness was introduced for certain aircraft) was written by the inspector. This meant the inspector had not seen an anticipated review of airworthiness outlined in the standard letter to the operator that would confirm the helicopter conformed to the type certificate.

- The CAA used a checklist, ‘Maintenance and New Zealand Logbook Checklist’, as part of its process. Under the heading in Section B: NZCAR Maintenance Requirements (CAR 91.605) next to ‘Review of Airworthiness ARA’, a hand-written note had been made ‘waiting copy’. This was further evidence that the CAA had not received a copy of any review of airworthiness form at the time it inspected the helicopter.

- On 8 September 2014 the CAA certified on the process worksheet that: ‘all requirements of CAR Part 21 Subpart H for the issue of an airworthiness certificate in respect of the subject work request have been satisfied, and the certificate has been granted according to CAA procedures’. On the same day, the inspector also signed that the work was complete.

- According to the CAA, when it accepted a review of airworthiness as evidence of conformity for an aircraft that did not have an export airworthiness certificate, it was not uncommon for the applicant to send a copy of the review of airworthiness form to the CAA after the CAA airworthiness certificate inspection had been completed by the CAA inspector. This was reflected in the entry made on the checklist for this helicopter ‘waiting copy’ in the ‘outstanding items’ section.

- However, the airworthiness certificate was issued to the operator on 21 August 2014 without the CAA ever having received the required review of airworthiness. Refer Appendix 3 for a summary of the sequence of events relating to the helicopter’s airworthiness.

Quality control relating to the issue of airworthiness certificates

- The CAA inspector was employed primarily as an air transport inspector, but had been seconded periodically to the aircraft certification unit to conduct airworthiness certificate inspections. The inspector had previous experience overseas as an airworthiness inspector and had received training on the New Zealand requirements. The inspector had completed approximately six airworthiness certificate inspections in New Zealand. However, this was the first application for an aircraft that had been imported without an export certificate of airworthiness.

- The CAA submitted that its inspectors were not experts on each helicopter type and might rely on the expertise of the persons who prepared a helicopter for the CAA inspection. Those persons would be licensed engineers who were rated on the aircraft type and held an inspection authorisation.

-

In respect of the standard for a CAA inspection, the CAA internal procedure states:

If any work on the aircraft has not been completed and the aircraft is not in a condition ready to fly the inspector should inform the certifying engineer that he/she is not able to do the inspection. He/she should specify the reasons and then depart.

-

The internal procedure also states:

Where the aircraft does not comply with [CAR] 21.191 and a certificate is not able to be issued, the maintenance organisation or aircraft owner is to be clearly advised what the outstanding requirements are.

- At the time of the CAA inspection the inspector noticed disparities between the detail of components listed on the application form and the detail in the maintenance records. That would have been an opportunity for the inspection to have been postponed until all maintenance issues had been resolved.

- The established practice of the CAA of completing its inspection of an aircraft before having received the required review of airworthiness was not in accordance with its own processes and left an opportunity to miss an aspect that was critical for ensuring the aircraft was actually airworthy before a certificate of airworthiness was issued.

-

The CAA submitted that an inspector was solely responsible for the assigned process for issuing an airworthiness certificate, without any supervision or secondary checking. The lack of supervision of this process within the CAA, particularly in this case given the inspector’s relative inexperience with the New Zealand process, meant that errors and omissions could go undetected.

- In this case, the processes in place designed to ensure that the helicopter was airworthy when it entered the New Zealand system were not followed. There is no evidence of any technical issue with the helicopter contributing to this accident. Nevertheless, there was real potential for unsafe conditions to have existed with the helicopter that could affect aviation safety.

Issues with the helicopter maintenance records

Safety issue: The number and nature of the maintenance anomalies involving the accident helicopter and the three other helicopters operated by Helipro are an indication that there could be historical or latent maintenance issues with some of its other aircraft that have been on-sold and are currently being operated on the New Zealand register by various other companies.

- When this helicopter was imported in March 2014, it had neither an export nor domestic certificate of airworthiness issued by the United States, and this was stated on its application to the CAA. In its letter acknowledging the application, the CAA advised that ‘in the absence of an export certificate of airworthiness the CAA will usually accept an annual review of airworthiness’. This means of complying with the New Zealand Civil Aviation Rules was not referred to in either the associated Advisory Circular (Advisory Circular AC 21-2 Product Certification – Airworthiness Certificates in the Standard and Restricted Categories) or the CAA’s procedures.

- Helipro had included with its application copies of the ‘current aircraft status’ sheets that had accompanied the imported helicopters. The sheets identified each significant component of the helicopters by part number and serial number. Helipro had exchanged a number of components before presenting the helicopter to the CAA for its entry inspection. The CAA entry inspection was performed by the CAA at the operator’s premises on 21 August 2014 (Helicopter B was registered by the CAA and the operator applied for an airworthiness certificate, but the application was cancelled. The CAA did not inspect helicopter B). The inspector noticed that some parts on the helicopter were different from those that had been installed when it was imported, but did not notice that the maintenance documentation associated with the component changes was incomplete.

- The operator’s records for maintenance carried out prior to the airworthiness certificate inspection were kept in a binder entitled ‘C of A Inspections job#1269’. The binder also included other records for an associated job number 1507. The maintenance included reassembly of the helicopter, a change of both engines, installation and modification of various components and equipment, rectification of defects, and scheduled inspections that had been carried out by engineers approved under Helipro’s CAR Part 145 exposition.

- There were a number of anomalies with the records for these various maintenance and inspection tasks. Examples of these are described below.

- Both engines had been changed for the engines that were originally on helicopter B. This change had been recorded in maintenance worksheets; however, there was no reference to, or record of, any conformity inspection or approved release being carried out on the engines by an appropriately authorised person, as required by CAR Part 21.

- Maintenance logbook entries showed that, after the helicopter had been imported in January 2014, its freewheel assemblies had been removed on 20 March 2014 and installed in a Kawasaki BK117 (registration ZK-HYZ) operated by Helipro at the time. The freewheel assemblies being replaced had overrun their life limits by 17.1 hours.

- The maintenance records for transferring the freewheel assemblies from the helicopter to ZK-HYZ recorded that they had a significantly longer time in service remaining than the recorded time in service remaining when they were imported on the helicopter.

- The CAA advised the Commission that the requirement to maintain the helicopter in accordance with the rules commences on the date of registration of the helicopter in New Zealand.

- The engine changes occurred on 6 June 2014, which was more than two months after both the helicopter and helicopter B (from which the engines were taken) had been issued with a New Zealand certificate of registration. Therefore, the certifying engineer needed an ‘authorised release certificate’ (a statement issued by an approved organisation that the item is fit for release to service) (CAA Form 1) for the engines, issued by an organisation that was authorised to issue such a certificate, before issuing the certificate of release to service on 1 August 2014 for the installation. There was no reference in the worksheets to a CAA Form 1, and no CAA Form 1 was found in the aircraft records.

- Senior personnel from Helipro Maintenance, the operator and some CAA staff involved in the issue of the airworthiness certificate perceived there was no need for CAA Form 1 for components (such as engines) because they were changed prior to the date of the helicopter’s airworthiness certificate inspection. This was not consistent with the CAA’s view that Civil Aviation Rules applied once the helicopters were registered.

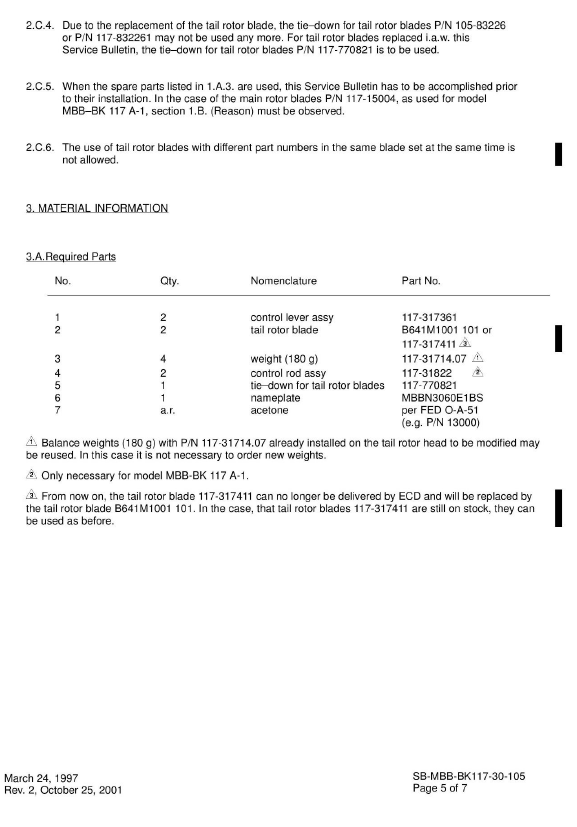

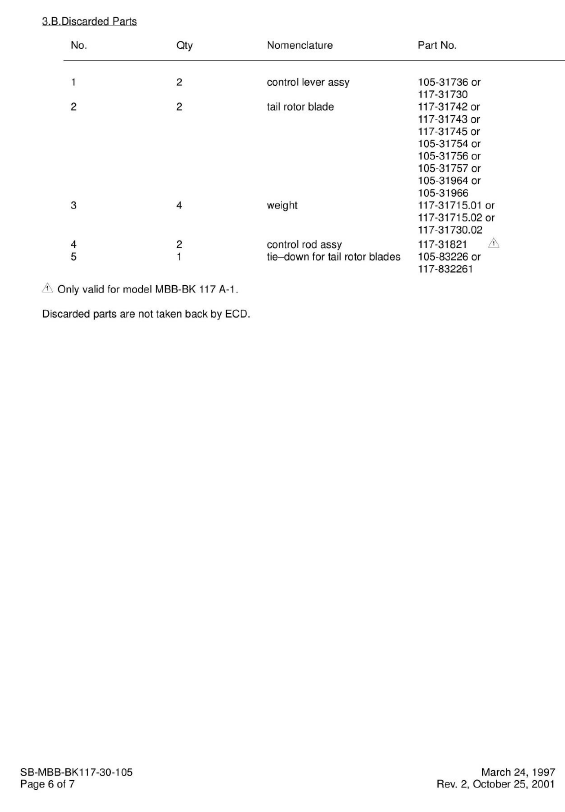

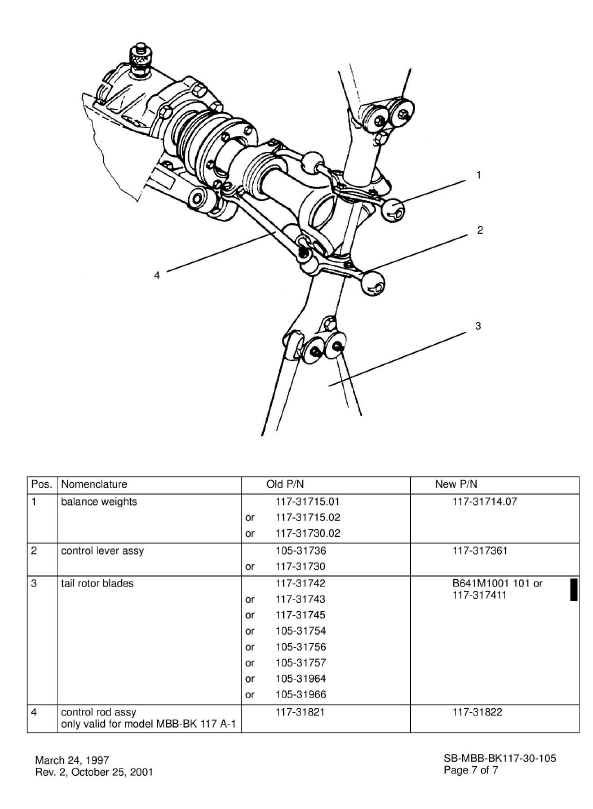

Tail rotor modification

- In 1997 Eurocopter advised (Eurocopter Service Bulletin SB-MBB-BK 117-30-105, first issued in March 1997, refers (see Appendix 3)) that production of tail rotor blades would change to a wider chord (the measurement from the leading edge of the blade to the trailing edge, essentially the width of the blade) blade that had the following advantages:

- tail rotor blades may be replaced individually

- increased thrust of tail rotor

- improved damage tolerance

- lower maintenance and operating costs.

- The wide chord blades had a different part number to the earlier ‘narrow’ chord blades, and their use required the tail rotor head to be modified. This was accomplished by changing the part number of the existing tail rotor head.

- According to the maintenance records, the wide chord tail rotor blades with modified tail rotor head were installed on the helicopter in the USA on 1 May 2009. The ‘current aircraft status’ records, which accompanied the helicopter at importation and were provided to the CAA with the application for an airworthiness certificate, showed that the helicopter had been imported with the wide chord blades installed. The ‘current aircraft status’ records also noted: ‘Only T/R [tail rotor] blades [part number] 117-317411 or B641M1001101 (wide chord) can be used on this tail rotor head’.

- A picture of the helicopter, taken by the CAA at the time of the airworthiness certificate inspection, showed that the helicopter had ‘narrow’ chord tail rotor blades fitted (the narrow chord and wide chord blades had noticeably different shapes). The narrow chord blades were fitted at the time of the accident, but the tail rotor head part number was that for wide chord blades.

- No maintenance entries associated with the change of wide chord blades back to narrow chord blades could be found.

- Airbus Helicopters advised there were no manufacturer’s instructions for reverting the modification status of the tail rotor to the superseded narrow chord blades once wide chord blades and modified tail rotor head had been installed.

- Airbus Helicopters also advised that the thrust from the narrow chord tail rotor, installed on the helicopter at the time of the accident, would have been 6.8% less than the thrust from the wide chord tail rotor. However, having higher tail rotor thrust available is not regarded as the only factor in preventing unanticipated yaw. If the pilot does not adequately anticipate tail rotor demand, unanticipated yaw can occur. Airbus Helicopters could not determine from the information provided whether the narrow chord blades contributed to the unanticipated yaw.

- These anomalies described above are of concern. The Commission raised the safety issue with the CAA for it to address. In response, the CAA issued a Continuing Airworthiness Notice to notify owners and operators of possible significant anomalies with the maintenance and engineering practices relating to certain aircraft. The full notice is included in Appendix 4.

Findings Ngā kitenga

- No mechanical failures were found that would have likely contributed to the accident.

- The directional control of the helicopter was lost, likely due to unanticipated right yaw.

- Operational pressure likely increased the risk of the pilot becoming distracted.

- There were a number of significant anomalies in the maintenance records for the helicopter that were left unresolved at the time the CAA issued a certificate of airworthiness for the helicopter. None of these anomalies was a factor contributing to the accident.

- The helicopter had not undergone all of the inspections and verification of maintenance tasks required before it was issued with a certificate of airworthiness.

- There were a number of maintenance anomalies with other aircraft owned or operated by Helipro prior to the accident.

- The CAA policies, processes and procedures for issuing certificates of airworthiness for imported second-hand aircraft did not have the robustness of a good-quality management system.

Safety issues and remedial actions Ngā take haumaru me ngā mahi whakatika

General

- Safety issues are an output from the Commission’s analysis. They typically describe a system problem that has the potential to adversely affect future operations on a wide scale.

- Safety issues may be addressed by safety actions taken by a participant, otherwise the Commission may issue a recommendation to address the issue.

Maintenance anomalies

- The number and nature of the maintenance anomalies involving the accident helicopter and the three other helicopters operated by Helipro are an indication that there could be historical or latent maintenance issues with some of its other aircraft that have been on-sold and are currently being operated on the New Zealand register by various other companies.

- The CAA issued Continuing Airworthiness Notice CAN-05-008 addressing this issue. It was subsequently withdrawn after no reports were received.

- In the Commission’s view, this safety action has addressed the safety issue. Therefore, the Commission has not made a recommendation.

Process for entering second-hand imported aircraft into New Zealand

- The date when a helicopter is imported to New Zealand is the point when it enters the New Zealand regulatory system. It is important that the risks of importing second-hand aircraft are understood and mitigated by following robust procedures, because any anomalies that are not identified at that point can stay with the helicopter for some time and present a risk to safe operation.

- In this case, the CAA’s process for entering second-hand imported aircraft into the New Zealand regulatory system was not clearly defined; was not clearly understood by some staff; and did not have the necessary checks to ensure the proper process had been followed. Although there is no evidence of any technical issue with the helicopter contributing to this accident, there was real potential for unsafe conditions to have existed with the helicopter that could affect aviation safety.

- The CAA has taken the following safety action to address this issue:

- The CAA arranged an independent review of the process for issuing of a certificate of airworthiness, including the conformity inspection process for second-hand aircraft.

- The Commission welcomes the safety action to-date. However, it believes more action needs to be taken to ensure the safety of future operations. Therefore, the Commission has made a recommendation in Section 6 to address this issue.

Recommendations Ngā tūtohutanga

General

- The Commission may issue, or give notice of, recommendations to any person or organisation that it considers the most appropriate to address the identified safety issues, depending on whether these safety issues are applicable to a single operator only or to the wider transport sector.

- In the interests of transport safety, it is important that recommendations are implemented without delay to help prevent similar accidents or incidents occurring in the future. In this case, a recommendation has been issued to the Civil Aviation Authority.

New recommendation

-

The Commission recommends that the Civil Aviation Authority amend its policies and procedures for issuing certificates of airworthiness for imported second-hand aircraft to ensure that the appropriate audit and assurance processes are in place and the procedures are consistently applied. (005/20)

On 9 June 2020, the Civil Aviation Authority replied:

The CAA has considered the final recommendation to amend its policies and procedures for issuing certificates of airworthiness for imported second-hand aircraft.

Notwithstanding the evidence already provided earlier to the Commission that addressed the issue, the CAA will accept the final recommendation as part of a programme that will see a more holistic/capability approach for an aircraft type acceptance process.

Key lessons Ngā akoranga matua

- Pilots can experience distraction during all phases of flight. Pilots must remain vigilant to ensure that their performance is not degraded by distraction when attending to various tasks necessary to the safe operation of an aircraft.

- Unanticipated yaw is a flight characteristic to which all types of single-rotor helicopter can be susceptible. Pilots need to remain cognisant of the conditions in which the phenomenon is likely to occur and the actions required for recovery.

- The disclosure of medical conditions and prescribed medication to the CAA ensures that their aeromedical significance can be assessed. It does not automatically preclude a pilot from carrying out their duties, but does ensure a pilot can undertake them safely.

- It is essential that all maintenance and inspection tasks are conducted and properly recorded in accordance with applicable rules.

Data summary Whakarāpopoto raraunga

Details

latitude: 41° 5.8´

south longitude: 174° 53.2´ east

Conduct of the inquiry He tikanga rapunga

- The CAA notified the Commission of the accident at 1150 on Tuesday 2 May 2017. The Commission opened an inquiry under section 13(1) of the Transport Accident Investigation Commission Act 1990 and appointed an investigator in charge. A Commission investigator arrived at the accident site at 1630 on 2 May 2017 and made an initial assessment of the circumstances.

- The next day Commission investigators began to interview witnesses and supervised the process to recover the helicopter from the harbour.

- On 4 May 2017, in accordance with Annex 13 to the Convention on International Civil Aviation, the Commission notified the accident to the Bundesstelle für Flugunfalluntersuchung (BFU), the air accident investigation authority of Germany, the state of manufacture of the helicopter. The BFU appointed one of its investigators as its accredited representative and appointed Airbus Helicopters as its technical adviser.

- The Commission also notified the accident to the NTSB, the state of manufacture of the helicopter’s engines. The NTSB did not appoint an accredited representative, but provided technical support as required.

- The helicopter was recovered from the water on 4 May 2017, and taken to the Commission’s technical facility for further examination. On 6 May 2017, the utility pole, which was slung under the helicopter at the time of the accident, was recovered from the sea. It was weighed two weeks (the amount of water absorption was considered negligible) later by the electricity company that had contracted the helicopter operator.

- On 16 May 2017, the Commission’s investigators conducted a teleconference with the BFU and Airbus Helicopters’ advisers.

- On 19 May 2017, a specialist metallurgist conducted an initial assessment of a failure on the vertical fin spar (a primary structural member of the vertical tail fin). On 28 September 2017, the failed sections of the vertical fin were sent to the metallurgist for further examination.

- An Airbus Helicopters engineer travelled to New Zealand to assist the Commission with the technical examination of the helicopter, and the Commission engaged the services of a licensed aircraft maintenance engineer who had experience with the helicopter type.

- A GPS device recovered from the helicopter was sent to the Australian Transport Safety Bureau, which retrieved the data for the flight.

- The Commission obtained maintenance documents for the accident helicopter and also the records for another helicopter that had had components exchanged with the accident helicopter.

- On 21 December 2017, the Commission notified the CAA of a safety issue regarding the historical maintenance of aircraft previously operated or maintained by the former owner of the helicopter.

- On 21 February 2018, the Commission approved a draft interim report to be sent to seven interested persons for comment.

- The Commission received three submissions on the draft interim report. The Commission considered those submissions, and any changes made as a result were included in the final interim report.

- On 3 May 2018, the Commission published the interim report into this accident.

- On 9 April 2019, the Commission approved the draft final report to be circulated to interested persons for comment.

- The Commission received four submissions on the draft final report. The Commission considered those submissions, and any changes made as a result were included in this final report.

- On 5 August 2019, the sections of the vertical fin were sent to the DTA for further metallurgical examination using SEM.

- On 20 November 2019, the Commission approved the recirculation of the revised draft report to interested parties.

- The Commission received two submissions on the revised draft final report, and changes as a result of these have been included in the final report.

- On 24 April 2020, the CAA submitted further information to support its submission.

- On 20 May 2020, the Commission approved the final report for publication.

Glossary Kuputaka

- Advisory Circular

- Advisory circulars are guidance documents and not regulatory requirements

- Airworthiness

- A formal and periodic review of an aircraft and its records that is required for the aircraft to remain airworthy.

- Certificate of airworthiness

- A certificate (also called ‘airworthiness certificate’) issued by the regulator declaring that the aircraft meets the airworthiness requirements.

- Certificate of release to service

- A certification statement by a licensed aircraft maintenance engineer that maintenance has been performed in accordance with Civil Aviation Rules.

- Export certificate of airworthiness

- A certificate issued by an exporting country that the aircraft conforms to its type certificate

- Review of airworthiness

- An inspection of the aircraft and associated maintenance documentation to ensure that the aircraft is in an airworthy condition

- Spar

- A primary structural member

- Statement of conformity

- A statement made by an authorised person that an aeronautical product conforms to its design specification or type certificate.

- Type Certificate

- A Type Certificate is issued by a Regulatory Authority and signifies the airworthiness of a particular category of aircraft, according to its manufacturing design.

- Unanticipated yaw

- Uncommanded yaw of a helicopter that is not linked to any failure and is not related to full loss of tail rotor thrust

Citations Ngā tohutoru

CAA. (2007). Civil Aviation Authority Advisory Circular AC 21-2 Product Certification – Airworthiness Certificates in the Standard and Restricted Categories. Retrieved from https://www.caa.govt.nz/assets/legacy/Advisory Circulars/AC021 2.pdf.

FAA. (1995). Federal Aviation Administration Advisory Circular US FAA AC 90-95, Unanticipated Right Yaw in Helicopters.

Appendix 1. Defence Technology Agency SEM metallurgy report – excerpt

Examination

Supplied to DTA for analysis were the two primary halves of the fracture, labelled 17-004 E#8a and 17-004 E#8b. These samples will be referred to as 8a and 8b for the purposes of this report. A third sample sectioned from 8a as part of the Quest Integrity investigation was also supplied.

Visual examination of the as-received fracture surfaces revealed the presence of vast areas of impact damage, oxide deposits and debris. Solvent cleaning was undertaken to remove as much of the surface contamination as practical. Initial visual examination indicated overload. The fracture faces consistently exhibited fractures at 45° to the structure with a rough appearance that is associated with ductile overload fractures. No fracture faces exhibited indications of fatigue cracking or brittle fracture.

Following visual examination, all fracture surfaces and surrounding areas of interest were optically examined under magnification. All fracture surfaces displayed similar ductile failure morphologies, consistent with fast fracture (overload). Despite the solvent cleaning efforts large areas remained concealed by oxides and debris, interspersed with scoring and smearing. No evidence of fatigue or pre-existing cracks was found.

The section of the structure was removed for SEM inspection. This section was selected for high magnification SEM analysis as it contains fastener holes, tight radii, and other stress raisers, which are possible crack initiation sites.

SEM analysis microscopy showed consistent overload morphology at higher magnifications. On much of the fracture face feature definition was diminished due to widespread surface corrosion and damage. There were no obvious fatigue progression or arrest marks on the fracture surface and no obvious crack origin.

Discussion

Inspection of the fracture surfaces from the tail fin of ZK-IED was conducted from low to high magnification utilising magnifying eyepieces, a Leica M165 macroscope and SEM. Optical examination did not suggest there were any pre-existing cracks or fatigue cracking that had contributed to the failure of the component.

Appendix 2. Airbus Helicopters Safety Information Notice No. 3298-S-00

Appendix 3. Sequence of events related to the accident helicopter

Appendix 4. Eurocopter Service Bulletin SB-MBB-BK 117-30-105

Appendix 5. Continuing Airworthiness Notice (CAN) 05-008

Appendix 6. Advisory Circular AC 21-2, Airworthiness Certification Process

Document downloads

Related Recommendations

The Commission recommends that the Civil Aviation Authority amend its policies and procedures for issuing certificates of airworthiness for imported second-hand aircraft to ensure that the appropriate audit and assurance processes are in place and the procedures are consistently applied.