TAIC recommends law change to ban substandard ships from NZ. Commission’s final report on container ship Shiling finds the ship twice needed to be rescued and towed back to port in 2023, due to deferred maintenance. The Shiling had a history of deficiencies, both prior to a change of ownership in 2020 and after. TAIC found it is virtually certain the ship was unseaworthy when in NZ, despite holding valid certificates. TAIC also recommends closing gaps in international ship safety management systems and strengthening NZ’s salvage and rescue capability.

Executive summary Tuhinga whakarāpopoto

What happened

- On 15 April 2023, the container ship Shiling was under pilotage outbound from the port of Wellington and had just initiated a turn into the Wellington Harbour entrance channel when it suffered a blackout that caused the main engine to stop. The momentum of the turn carried the ship into the shallow waters of Falcon Shoal, where the bridge team succeeded in using both the ship’s anchors to stop the ship from grounding. The ship was subsequently towed dead-ship by harbour tugs back to its berth to be repaired.

- On 10 May 2023, the repairs having been made, the Shiling departed Wellington bound for Singapore. Because of forecast inclement weather for the Tasman Sea, the master decided to take shelter near the New Zealand coast and wait for about 36 hours for the weather to abate.

- Because of the length of time spent at Wellington, the bilge water holding tanks and the engine-room bilges were full, and water had begun to accumulate on the engine-room tank-top. When the Shiling entered the Tasman Sea, it began to roll, and the free water on the tank-top entered the void under the main engine sump, where three rubber diaphragms were located.

- The diaphragms linked the main engine sump to the main-engine lubricating oil tank (lube-oil tank) beneath. Their purpose was twofold: to compensate for the relative movement between the main engine and the solid structure of the tank; and to prevent water entering the lube-oil tank. However, all three rubber diaphragms were in a deteriorated state and allowed the bilge water to enter the lube-oil tank, causing the lube-oil pumps to lose pressure and the main engine to stop.

- Without the main engine operating, the Shiling was unable to manoeuvre. The ship settled with its beam to the swell and began to roll heavily. With no option for recovering the main engine, the master made a Mayday call. A tow-capable vessel located in the nearby port of New Plymouth responded, initially taking the Shiling in tow to the sheltered waters of Golden Bay and eventually back to Wellington for further repairs.

Why it happened

- The ship’s blackout in Wellington Harbour was caused by exhaust gases from a cracked cylinder liner in one of the generators entering the centralised cooling-water system that supplied cooling water to all generators and the main engine. The running generators tripped out because of high cooling-water temperature and caused the blackout, which subsequently caused the main engine to stop.

- Although the ship held valid statutory and classification society certificates, the generators and several other safety-critical systems were found to be in a deteriorated condition.

- It is very likely that the rubber diaphragms had not been inspected for many years, despite the issuing of several bulletins by insurance clubs and engine manufacturers warning of the critical importance of maintaining the diaphragms in good condition.

- The Transport Accident Investigation Commission (the Commission) has identified several safety issues relating to the international and domestic systems for regulating international ships and the ability of ship owners to devolve their responsibilities for the safe operation of their ships to third parties without regulatory consequences.

- The Commission has made recommendations to Maritime New Zealand to address these matters through the International Maritime Organization (IMO).

What we can learn

- Deferred ship maintenance, especially of critical equipment and systems, will significantly increase the risk of accidents and incidents.

- Failures involving critical equipment and systems must be fully investigated for their causes and resolved before the equipment or systems are placed back in service.

- The creators of risks are best placed to manage them (Committee on Safety and Health at Work, 1972). A ship owner who offers a ship for service must remain responsible for its safe operation, regardless of any other entities involved in operating, inspecting and auditing the ship and its systems.

Who may benefit

- All ship owners and operators (including ship managers), port state, and flag state regulators, classification societies, insurance providers and deck and engineering officers may benefit from the findings of this inquiry.

Factual information Pārongo pono

Background

- The container ship Shiling was built in 2005. In September 2019 the now owner of the Shiling engaged the services of Asian-Alliance Ship Management Pte Ltd (Asian-Alliance) to source and purchase four container ships; one was the Shiling. Asian-Alliance undertook the pre-purchase inspection for the owner, who then purchased the vessel in 2020.

- The owner changed the 'flag' of the vessel to Singapore and the classification society to Lloyd’s Register (Lloyd’s).

- In February 2020 Asian-Alliance became the vessel’s ‘operator’ on behalf of the owner. The Shiling was then used to provide a liner service between New Zealand and ports in Asia.

- In the year before the owner purchased the Shiling, the vessel had had 19 deficiencies issued against it in 5 Port State Control (PSC) inspections in Russia, China and Chile (Chile did not issue any deficiencies).

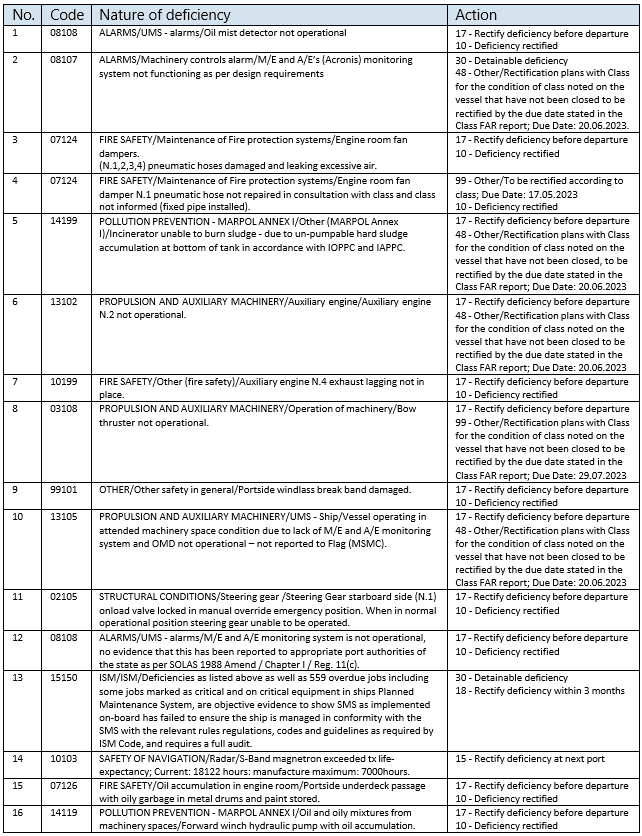

- Between March 2022 and March 2023, Maritime New Zealand (MNZ) had issued 16 deficiencies against the Shiling during 3 PSC inspections, the last one being a month before the first incident.

- During a voyage in February 2022, the Shiling’s main engine had failed to start several times during an arrival under pilotage at Wellington.

- In July 2022 the Shiling had again suffered a main engine failure when departing Wellington under pilotage. The vessel had been taken to anchor then returned to its berth for repairs. Maritime New Zealand had issued a Notice of Imposition of Conditions (Section 55, Maritime Transport Act 1994) requiring a leaking fuel valve on the main engine to be repaired.

- Since August 2018 the Shiling had been classified as a ‘high risk’ vessel under the Tokyo PSC Memorandum of Understanding.

First incident – 15 April 2023

- The Shiling was on a routine call to Wellington as part of its liner service between ports in New Zealand and Asia.

- Cargo operations had been completed on the evening of 14 April 2023, and the pilot had been ordered for 0530 (Times in this report are in New Zealand Standard Time (Coordinated Universal Time + 12 hours) and are expressed in the 24-hour format) on 15 April 2023.

- At about 0330 on 15 April 2023, the oiler (who was on watch in the engine room) called the fourth engineer after noticing aerated water overflowing from the cooling-water expansion tank. The Shiling had a centralised cooling-water system that provided cooling for the main engine and all four generators. The expansion tank provided a residual/reserve cooling water for this system.

- Two of the four generators were running: generator 2 and generator 4. The fourth engineer noted that the high cooling-water temperature alarm had activated for both running generators. The fourth engineer called the third engineer and the second engineer to assist.

- At 0358 generator 2 shut down because of high cooling-water temperature. Generator 4 continued carrying the electrical load but with an elevated cooling-water temperature. Air had entered the cooling-water system through a crack in one of the cylinder liners on generator 2. The crew were not aware of this fault at that time. Because of the configuration of pipes in the cooling-water system, generator 4 was the least affected by the aeration of the cooling water.

- At 0400 the bridge gave the engine room one hour’s notice of departure. The chief engineer was called and arrived in the engine room shortly afterwards. Together the engineers began purging air from the cooling-water system to improve cooling for the generators.

- The pilot boarded at about 0515. The Shiling needed three of its four generators to be running when under pilotage in enclosed waters, to provide sufficient reserve electrical load capacity. When the pilot boarded, the engineers were still trying to overcome the cooling-water problem and start and connect three generators on-line. The engineers were trying to connect generators 2 and 3 (generator 4 was already running and generator 1 was under repair and not available).

- At 0600 the chief engineer telephoned the bridge and told the master that three generators were now available. Preparations were then made for departure.

- At 0620 the control of the main engine had just been passed from the chief engineer to the bridge when generators 2 and 3 shut down because of high cooling-water temperature. Generator 4 continued supporting the electrical load, albeit with an elevated cooling-water temperature.

- For the next hour the engine crew worked on purging air from the cooling-water system and restarting generators 2 and 3. At 0724 the chief engineer telephoned the master and confirmed that three generators were running, and the engine room was ready for departure. At this time none of the engineers was aware of why the cooling water-system had become aerated. They were unaware that generator 2 had a cracked cylinder liner.

- At 0736 the Shiling departed the berth under the conduct of the pilot and assisted by two harbour tugs.

- By 0748 the two tugs had been let go and the ship was heading outbound and approaching Falcon Shoal, about to enter the Wellington Harbour entrance channel.

- At 0809 the pilot initiated a starboard turn into the entrance channel when generators 2 and 3 shut down because of high cooling-water temperatures. Generator 4 was unable to absorb the total electrical load and also shut down. The Shiling suffered a total blackout and the main engine stopped.

- The emergency generator auto-started almost immediately, as designed. The emergency generator supplied power to essential services, including one of the two steering motors, which automatically started one minute later.

- The ship had been swinging to starboard towards Falcon Shoal when the main engine stopped. After a short delay, the pilot let go first the port and then the starboard anchor, which resulted in the ship stopping just before it was about to run aground inside the shoal. The pilot had delayed letting go the first anchor until the ship’s bow was clear of the adjacent Falcon Shoal Beacon (see Figure 3).

- The pilot ordered the tugs to return to the ship to assist. At 0938 the engineers were able to restart generator 4, which provided sufficient electrical power to begin recovering the anchors.

- The starboard anchor was aweigh at 1028. However, generator 4 was unable to sustain the service electrical load at the same time as using the anchor windlass and kept disconnecting from the switchboard.

- Meanwhile, the Wellington Regional Council harbourmaster and MNZ had responded to the incident, with MNZ issuing a notice requiring the Shiling to be towed by the harbour tugs back to its berth at Wellington and the harbourmaster directing that the ship be removed from where it was anchored and taken back to its berth.

- The port anchor was eventually aweigh at 1336, after which the ship was towed dead-ship (see Maritime Transport Act 1994, Section 55(2)(a)) back to its berth at Wellington for repairs, berthing at 1537.

- On that same day MNZ issued the master of the Shiling with a Notice of Imposition (See Maritime Transport Act 1994, Section 55(2)(a)), prohibiting the Shiling from departing Wellington until its generators and main engine were fully operational to the satisfaction of its classification society, Lloyds.

- On 17 April 2023, MNZ conducted a PSC inspection and identified, amongst other deficiencies, several International Safety Management (ISM) Code deficiencies and 559 overdue jobs in the vessel’s planned-maintenance system marked as critical and on critical equipment. Having identified numerous deficiencies (see Appendix 1 for the MNZ list of deficiencies), MNZ suspended its inspection and detained the Shiling. Maritime New Zealand notified both the Maritime & Port Authority of Singapore (MPA) and the vessel’s classification society, Lloyds, of the detention.

- Lloyds, upon being notified of the vessel’s detention, sent a surveyor to assess the vessel against its class rules (standards).

- On 9 May 2023, MNZ resumed its PSC inspection looking at areas of concern and reinspecting areas identified as deficient in its first inspection. Further deficiencies were found and raised with both the MPA and Lloyds.

- The Shiling remained at Wellington for 25 days, undergoing repairs to its generators and rectification of the deficiencies identified by MNZ and class issues identified by the attending classification society surveyors (some, but not all, deficiencies identified by MNZ were also deficiencies under class rules).

- In addition to the Lloyds survey, the MPA appointed Lloyds as its recognised organisation (rather than provide their own surveyors, flag states can opt to appoint approved survey organisations to conduct inspections on their behalf) for conducting an extended survey and ISM Code audit (ISM renewal audit). The MPA instructed Lloyd’s to survey beyond what had been identified during Maritime New Zealand’s PSC inspection.

- On receipt of the Lloyd’s final survey report as the recognised organisation and completion of the additional survey of expanded scope and ISM renewal audit, the MPA permitted the Shiling to undergo a single voyage to Singapore, where its cargo would be discharged, and then to a port in Asia for drydock. Lloyd’s, as the recognised organisation for the MPA, raised several conditions of class (an acknowledgment that the vessel doesn’t comply with a class rule or standard) and statutory findings against the ship. The due date for most of the conditions to be rectified was 29 July 2023, by which time the planned drydock would be completed.

- Following sign-off by Lloyds and the MPA, MNZ lifted the detention notice, allowing the Shiling to depart Wellington.

Second incident – 12 May 2023

- The Shiling departed Wellington bound for Singapore at 0900 on 10 May 2023. While a vessel is in port, any accumulation of oily water must be stored in tanks for later controlled discharge away from any coastline. Due to the length of the Shiling’s stay at Wellington, the various tanks used to store oily water were at capacity. The engine-room bilges were confirmed as dry before the ship departed. The chief engineer intended to begin pumping out these tanks through the approved oily water separator once the ship was outside New Zealand’s territorial waters.

- However, there was an adverse weather forecast for the Tasman Sea, so the master elected to slow-steam (the deliberate reduction of a ship’s speed) and drift for about 1.5 days in the shelter of the New Zealand coast.

- At about 2300 on 11 May 2023, the Shiling departed the sheltered waters of the New Zealand coast bound for Singapore. Because the engineers had been unable to begin pumping out the oily water holding tanks, additional oily water that had been produced while the ship remained in sheltered waters had filled the engine-room bilges and begun accumulating on the engine-room tank-top

- As the vessel ventured into open sea and began to roll, this water began sloshing and entered the void space between the sump of the main engine and the main-engine lubricating-oil tank (lube-oil tank) beneath the engine-room tank-top (see Figure 4).

- When functioning normally, lubricating oil injected into the various components of the main engine gravitated to the main-engine sump37, referred to as a dry sump. There were three drain ports in the bottom of the main-engine sump. Oil gravitated through these drain ports into the lube-oil tank below the tank-top. Lube oil is drawn from this tank, purified and filtered and then returned to the tank on a continuous cycle. Lube oil was drawn from this tank by the main-engine lube-oil pump and injected into the various components above in a continuous cycle.

- Rubber diaphragms were fitted between the drain ports in the main-engine sump and the lube-oil tank below. The main engine was mounted on resilient mounts to absorb vibration, while the lube-oil tank below was fixed to the ship’s structure. The purpose of these rubber diaphragms was to compensate for the relative movement between the main engine on its resilient mounts and the rigid lube-oil tank below and prevent any water that could accumulate on the tank-top entering the lube-oil tank.

- However, the rubber diaphragms in the Shiling had all deteriorated with age. When the oily water entered the void between the main engine sump and the lube-oil tank, it entered the lube-oil tank through the deteriorated rubber diaphragms and contaminated the lube oil in the tank.

- The contaminated lube oil caused a drop in pressure supplied by the lubricating oil pumps, and this caused the main engine to stop at about 0730 on 12 May 2023. This was about eight hours after the Shiling had resumed its voyage to Singapore after sheltering along the New Zealand coast, and at a time when it was heading into 5- to 6-metre waves.

- Given the contamination of the lube-oil tank, the engineers were unable to restart the main engine. Without propulsion, the Shiling settled beam-on to the waves and began rolling heavily (up to 45 degrees to port and starboard).

- At 0828 the master radioed the New Zealand marine operations centre and appraised the operator of the situation. The master requested assistance in the form of a tow. The operator considered that the master had issued a Pan-Pan call and passed the message on to the New Zealand Rescue Coordination Centre. The Centre began searching for a suitable tow vessel. The Shiling was about 30 NM northwest of Farewell Spit at 40ᵒ 09.92’ south, 172ᵒ 21.22 east.

- At 1056, due to continued heavy rolling, the master made a Mayday call.

- A suitable tow vessel, the Skandi Emerald, was located in New Plymouth. It departed New Plymouth at 0900 on 12 May, arriving at the Shiling at 1630 the same day.

- The Skandi Emerald established a tow by 1730 and began towing the Shiling towards the shelter offered in Golden Bay.

- The Shiling was anchored in Golden Bay at about 1730 on 13 May 2023, and was eventually towed by the Skandi Emerald back to Wellington, arriving on 23 May 2023 (see Figure 5).

- On 29 May 2023, MNZ issued a detention notice to the master of the Shiling, preventing the vessel sailing pending confirmation from Lloyd’s (as the classification society) and the MPA (as the flag state) that the cause(s) of the main engine failure had been identified and rectified and that the vessel was seaworthy for the resumption of its intended voyage to Singapore.

- The Shiling remained at Wellington for 45 days, undergoing surveys and repairs to the main engine, further repairs to the generators in connection with the first incident, and repairs to several other systems identified as substandard during respective class and flag state inspections.

- Maritime New Zealand lifted the detention notice on 7 July 2023, allowing the Shiling to sail for Singapore.

Vessel information

- The Shiling was a fully cellular container ship, built in 2005 by HD Hyundai Heavy Industries in South Korea (referred to as a Wärtsilä RT-flex96C following a series of joint ventures and mergers between various Wärtsilä and Sulzer entities between 1984 and 2007 that eventually became Wärtsilä Corporation). The ship was 294.4 m in length overall and 32.2 m in breadth and could load a maximum of 5117 20-ft containers.

- The single main engine was a Sulzer 8RT-Flex96C-B, capable of developing

- 45,760 kilowatts (kW) at 102 revolutions per minute (rpm), built by HD Hyundai Heavy Industries in South Korea.

- The generator plant comprised two MAN B&W 7L27/38 generators, each capable of developing 1990 kW, and two MAN B&W 6L27/38 generators, each capable of developing 1700 kW, ie, four generators in total).

- The ship was also fitted with an 1800 kW bow thruster, which was not operational at the time of the incidents.

Inspections, tests and research

Engine-room alarm monitoring system

- The Acronis engine-room alarm and control monitoring system supports the concept of Unattended Machinery Space (UMS). When a ship has an approved UMS endorsement, the engine room can operate unattended at sea. The system monitors all key machinery parameters and sends an alarm to a designated engine-room watchkeeper if any set parameter is exceeded. In this way the engine-room staff can work daytime hours on routine maintenance and overhauling machinery.

- However, for at least one year before these incidents the Acronis (alarm and control integrated system) had suffered from an inordinate number of alarm conditions, so many that the engineer officers had been compelled to maintain a 24-hour watch. The ship’s crew reported that the status of the Acronis system had steadily deteriorated in the previous 12 months. Lloyd’s required the faulty status of the Acronis system to be reported, but that had not been done.

- In an investigation at Wellington after the incidents, Lloyd’s found that a high percentage of the alarm conditions had been caused by faulty sensors and wiring. Lloyd’s temporarily suspended the UMS endorsement pending the system being repaired and reinstated to Lloyd’s satisfaction.

Generators

- Once the Shiling had been towed back to its berth after the blackout incident in Wellington Harbour on 15 April 2023, investigations had begun into determining the cause of the blackout.

- A crack was discovered in the cylinder liner of generator 2. This had provided the point for gases to enter the jacket cooling water for that cylinder and then into the centralised cooling water system.

- Generator 2 was due for overhaul, having just reached its maximum running hours, and was able to achieve only 60 per cent of its maximum continuous rating. There were insufficient spare parts on board to conduct the overhaul.

- Generator 1 had been inoperative since 2021. Since joining the ship nine months before these incidents, the chief engineer had begun a programme of progressively overhauling the generator, but at the time of these incidents it was only capable of achieving 40 per cent of its maximum continuous rating and was unable to be synchronised with the other generators. Generator 1 was not available to be used at the time of these incidents.

- Generator 3 was overdue for overhaul and could achieve only 60 per cent of its maximum continuous rating. The spare parts required for the overhaul were onboard, but the crew had not been able to conduct the work because of other work commitments.

- Generator 4 was also overdue for overhaul and could achieve only about 60 per cent of its maximum continuous rating. The spare parts required for the overhaul were onboard, but the crew had been able to overhaul only three of the six cylinders due to other work commitments.

- Because of a combination of faults with the generators and the generator power management system, automatic synchronising and load sharing between the generators were not possible.

Main engine

- When the Shiling arrived in Wellington, Asian-Alliance requested that a technician from Wärtsilä Korea attend the vessel. The Commission’s investigators also attended. On first inspection it was noted that the engine-room bilge located near the main-engine flywheel was full and water from this bilge was still lapping over the void under the main-engine sump.

- The main engine crankcase was opened to enable access to the three drain ports in the engine sump and to the rubber diaphragms fitted between these drain ports and the lube-oil tank below. It was observed that water had entered the lube-oil sump tank via the rubber diaphragms. The oil residue captured within the fold of the damaged diaphragm had emulsified where the water had entered and run down the steel pipe into the lube-oil tank (see Figure 6).

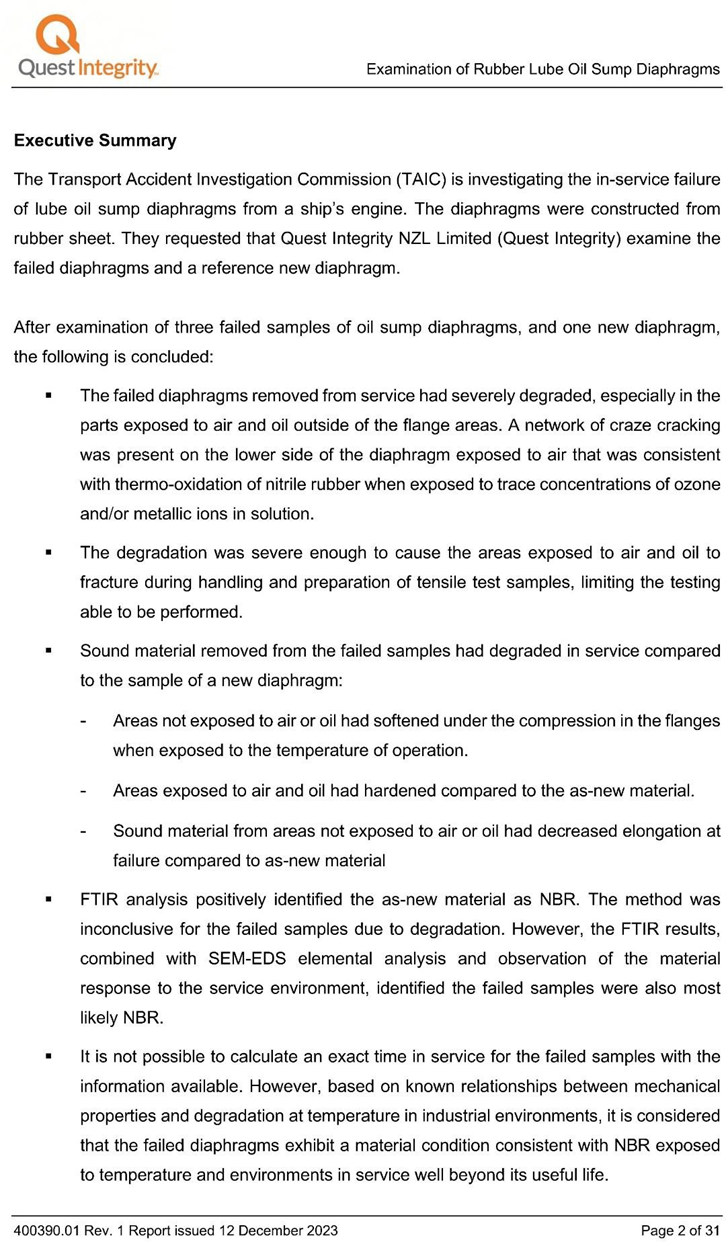

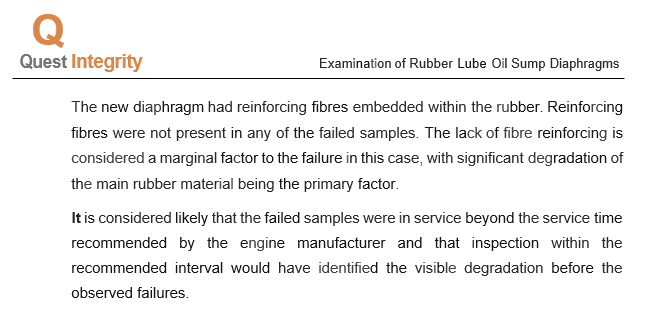

- All three rubber diaphragms were removed from the drain ports. All were observed to be damaged (see Figure 7). The three diaphragms were sent to Quest Integrity for examination and testing together with a representative new sample diaphragm supplied by Asian-Alliance.

-

The conclusions reached by Quest Integrity included the following (see Appendix 3 for an abridged version of the full report):

The failed diaphragms removed from service had severely degraded, especially in the parts exposed to air and oil outside of the flange areas. A network of craze cracking was present on the lower side of the diaphragm exposed to air that was consistent with thermo-oxidation of nitrile rubber when exposed to trace concentrations of ozone and/or metallic ions in solution.

The degradation was severe enough to cause the areas exposed to air and oil to fracture during handling and preparation of tensile test samples, limiting the testing able to be performed.

Sound material removed from the failed samples had degraded in service compared to the sample of a new diaphragm.

Areas not exposed to air or oil had softened under the compression in the flanges when exposed to the temperature of operation.

Areas exposed to air and oil had hardened compared to the as-new material.

Sound material from areas not exposed to air or oil had decreased elongation at failure compared to the as-new material.

It is not possible to calculate an exact time in service for the failed samples with the information available. However, based on known relationships between mechanical properties and degradation at temperature in industrial environments, it is considered that the failed diaphragms exhibit a material condition consistent with NBR exposed to temperature and environments in service well beyond its useful life.

It is considered likely that the failed samples were in service beyond the service time recommended by the engine manufacturer and that inspection within the recommended interval would have identified the visible degradation before the observed failures.

Meteorological and ephemeral information

- The weather conditions at Wellington on 15 April 2023, the day of the first incident, were fine and clear with light winds. There was negligible swell in Wellington Harbour where the blackout occurred.

-

When the Shiling departed Wellington at 0900 on 10 May 2023, the weather forecast issued for the sea area Cook (see Figure 8) at 0325 was:

Northwest 25 knots [nautical miles per hour], changing southwest 25 knots for a time around midday, rising to northwest 35 knots late evening. Sea becoming very rough. Southerly swell 1 metre developing. North of Cape Terawhiti: Northerly swell 2 metres developing. Poor visibility in periods of morning rain.

-

The Shiling spent most of 10 and 11 May 2023 slow-steaming or drifting in the northern part of sea area Cook. The weather forecast for sea area Cook issued at 2258 on 10 May 2023 was:

Northwest 25 knots, changing southerly 35 knots this morning, then easing to 25 knots this afternoon. Sea becoming very rough for a time. Southerly swell rapidly rising to 3 metres in the morning. Northerly swell 1 metre, easing. Poor visibility in morning showers.

-

The Shiling was to pass through sea area Stephens en route to the Tasman Sea. The weather forecast for the sea area Stephens issued at 0325 on 10 May 2023 was:

Northwest 20 knots, rising to northerly 30 knots in the morning. Changing westerly 40 knots late morning, then easing to 30 knots in the afternoon. Sea becoming very rough for a time. West of Farewell Spit to Hawera: Long period southwest swell rising to 5 metres late. Northwest swell 2 metres, easing. East of Farewell spit to Hawera: Westerly swell 3 metres developing. Poor visibility in showers. Possible squally thunderstorms.

-

The weather forecast for sea area Stephens issued at 2258 on 10 May 2023 was:

Westerly 35 knots, changing southerly 20 knots but 30 knots east of Cape Jackson to Hawera this morning. Becoming southerly 15 knots everywhere this evening. Very rough sea easing. West of Farewell Spit to Hawera: Long period southwest swell rising to 6 metres for a time. Elsewhere: long period westerly swell 3 metres, easing. Poor visibility in showers. Possible squally thunderstorms in the north this morning.

-

The weather forecast for sea area Stephens issued at 0616 on 11 May 2023 was:

Westerly 35 knots, changing southerly 20 knots but 30 knots east of Cape Jackson to Hawera this morning. Becoming southerly 15 knots everywhere this evening. Very rough sea easing. West of Farewell Spit to Hawera: Long period southwest swell rising to 6 metres for a time. Elsewhere: long period westerly swell 3 metres, easing. Poor visibility in showers. Possible squally thunderstorms this morning.

-

The Shiling resumed its voyage to the Tasman Sea at about 2300 on 11 May 2023. The weather forecast for sea area Stephens issued at 1627 on 11 May 2023 was:

Southerly 30 knots but 20 knots west of Stephens Island to Hawera. Becoming southerly 20 knots but variable 10 knots in the west this evening. Rough sea in the east, easing. West of Farewell Spit to Hawera: Long period southwest swell 5 metres easing. Elsewhere: Long period westerly swell 3 metres. Poor visibility in showers clearing late evening.

Personnel information

- The master of Shiling held a master foreign-going certificate and had been at sea for 31 years, 14 years of which as master. It was the master’s first time sailing on the Shiling, having joined the ship less than 1 month before the first incident.

- The chief engineer held a chief engineer (Class 1) foreign-going certificate and had been at sea for 30 years, plus 2 years as technical superintendent based ashore. The chief engineer had joined the Shiling for the first time 9 months before the incidents.

- The first officer held a first mate foreign-going certificate and had been at sea for 15 years, with the most recent 2 years as first officer. It was the first officer’s first trip on the Shiling, having joined 4 months before the first incident.

- The second engineer had been at sea for 25 years and held a second engineer (Class II) foreign-going certificate. It was the second engineer’s first trip on the Shiling, having joined 4 months before the first incident.

Recorded data

- The Commission recovered the following recorded data:

- The pilot’s portable pilot unit for the first incident, when the vessel suffered a blackout during departure. (The voyage data recorder information for this incident had been overwritten).

- The Shiling’s voyage data recorder for the period covering the second incident.

- The Automatic Identification System records for the entire period of both incidents, including the tow operation from Golden Bay to Wellington.

- The Acronis engine-room systems log.

- The Wärtsilä main-engine systems and alarm log.

- The data were used to inform the Commission’s inquiry.

- The data were used to inform the Commission’s inquiry.

Analysis Tātaritanga

Introduction

- When the Shiling sailed from Wellington on 15 April 2023 (the blackout incident), it is virtually certain that the ship was not in a seaworthy condition, despite holding a full suite of current statutory flag state and ISM certifications. Additionally, the ship had previously attracted numerous deficiencies through successive PSC inspections, which had resulted in a ‘high risk’ status under the PSC regime. The main engine had also failed under pilotage in New Zealand ports on two separate occasions about one year before these incidents.

- When the Shiling subsequently sailed from Wellington for Singapore on 10 May 2023 (the main-engine failure incident), it had undergone an extended period of maintenance and repairs under the scrutiny of MNZ, Lloyd’s and the MPA. However, when the Shiling’s main engine failed and it was towed back to Wellington, additional deficiencies were uncovered, some involving critical components and systems.

- The Commission has identified safety issues with the efficacy of the international regulatory system in ensuring the safety of ships and their crews, and the protection of the environment, in the current global shipping situation.

- The following section analyses the circumstances surrounding these incidents to identify those factors that increased the likelihood of the incidents occurring or increased the severity of their outcomes. It also examines any safety issues that have the potential to adversely affect future operations.

What happened during the blackout event

- All ships navigating in enclosed waters require additional generator capacity to absorb load fluctuations caused by the typical starting, stopping and constant running of various machinery. Running additional generator capacity would have reduced the risk of the ship experiencing a blackout and losing control when operating close to navigation dangers and other marine traffic.

- In its state of repair at the time, the Shiling usually required three generators to provide a sufficient level of redundancy, and that was without the high operational loads that would normally have been drawn by the bow thruster, which was inoperable at the time.

- Three generators were required because of the reduced capability of their diesel prime movers caused by deferred maintenance. A ‘standby’ generator was usually available to start automatically and share the electrical load if a problem occurred with any of the running generators. With three of the four generators required to meet operational demand, and the fourth (generator 1) not being fully operational, this safety measure was not available to the crew.

- The deferred maintenance of all four generators increased the risk of the ship blacking out under normal circumstances. The risk was further increased once the crack developed in one of the cylinder liners on generator 2, particularly as the vessel was fitted with a centralised cooling-water system that cooled all four generators and the main engine.

- The infiltration of exhaust gas into the cooling-water system had caused two successive shutdowns of generators 2 and 3. However, the crew did not attempt to establish how gas had entered the cooling-water system, even though the ship was about to enter pilotage. They focused instead on treating the symptom by purging gas from the system so that they could start three generators to enable the ship to sail.

- When the chief engineer informed the bridge that the engine room was ready for departure, the engineers did not know what had caused the aeration of the cooling-water system or the likelihood of the condition recurring. Neither the master nor the pilot sought an explanation of the two-hour delay from the chief engineer, and none was offered. When the Shiling departed the wharf, the risk of the problem recurring was high, and predictable.

- During their interview, the chief engineer stated that they had not been concerned about what was happening on the bridge, as their focus had been on the issues in the engine room. This had created an operational disconnect between the bridge and the engine crew. A similar operational disconnect was considered a factor in the grounding of the bulk carrier Funing under pilotage in Tauranga Harbour in July 2020. In that incident an evolving problem with the main engine had not been shared with the bridge team, resulting in an avoidable grounding (Transport Accident Investigation Commission, 2022).

- Because of the cooling-water pipe configuration, generator 4 was not as affected by the gases in the cooling-water system as generators 2 and 3. When generators 2 and 3 had shut down twice earlier in the morning, generator 4 had been able to sustain the electrical load because the ship was idle at the wharf and not working cargo, so had a reduced electrical load. However, while manoeuvring under pilotage the electrical load was greater. Consequently, when generators 2 and 3 shut down as the Shiling approached Falcon Shoal, generator 4 was unable to sustain the electrical load and shut down also, causing the ship to black out and the main engine to stop.

- The pilot’s actions, supported by the rest of the bridge team, were commendable and an example of good bridge resource management. It is virtually certain their actions prevented the ship grounding or striking Falcon Shoal Beacon.

- The directions given by MNZ and the harbourmaster that the Shiling be towed dead ship back to the port were prudent given the uncertainty of the status of the Shiling’s machinery.

What happened during the main-engine failure incident

- There was no direct correlation between this incident and the blackout in Wellington harbour, other than the substandard maintenance. The blackout event resulted from deferred maintenance of the ship’s power-generating plant, which was a safety-critical system. The main-engine failure resulted from a lack of maintenance of the rubber diaphragms, the purposes of which were to tolerate relative movement between the main engine and the ship’s structure and prevent bilge water entering the closed-loop lube-oil system. The diaphragms would also be considered a safety-critical component, depending on the definitions given of critical components.

- When the Shiling departed Wellington for the second time, all bilge water holding tanks were full because of the ship’s extended stay in port following the blackout event. Had the ship proceeded to Singapore without deviating for weather, the engineers would have been able to discharge the bilge water holding tanks to the sea via the ship’s oily-water separator. However, this was not permitted unless the ship was outside the New Zealand territorial sea.

- The master had reviewed the weather forecast and decided to remain in the shelter of New Zealand’s coastal waters until the weather in the Tasman Sea began to abate. While a ship is operating at sea it normally produces bilge water in the engine room, which is pumped either into holding tanks or out to sea via an oily-water separator. However, neither option was available because all the bilge water holding tanks were full and the ship was still in coastal waters. Consequently, the engine-room bilges were filled and water started accumulating on the engine-room tank-top. The Commission were unable to determine whether the chief engineer raised any concern with the master about the water accumulating on the engine-room tank-top.

- When the Shiling left the shelter of the coast and began to roll, the accumulated bilge water flowed across the tank-top and entered the void under the main engine sump. This would not normally have caused a serious problem, but the rubber diaphragms were aged and worn, enabling bilge water to enter the main-engine lube-oil holding tank.

- Once the amount of water in the lube-oil system reached a critical point (later tested at 11 per cent), the lube-oil pumps could not maintain the minimum lube-oil operating pressure. Delivering lube oil to the main engine at the correct pressure is critical to its performance. Any drop in lube-oil pressure to below a preset threshold will result in an automatic shut-down of the engine. This is what occurred.

- It would have been almost impossible to restart the main engine without removing the water from the lube oil, and even if it had been attempted, it would have risked serious damage to the engine. With the loss of propulsion, the ship settled beam-on to the heavy swell and began rolling severely, making it too dangerous to attempt recovering the main engine.

Rubber diaphragms

Safety issue 1: The International Maritime Organization’s definition of critical equipment and systems (a lack of which may create hazardous situations and/or cause accidents) is so broad that it is ineffective in defining what is critical and what is not.

- If the rubber diaphragms had not been degraded and damaged, the issue of bilge water flowing across the tank-top and under the engine sump would have had little or no effect on the integrity of the main engine.

- Allowing water to accumulate in an engine bilge to a point where it overflows the tank-top is to be avoided in any ship’s engine room(s). However, it is a foreseeable condition that can result for a variety of reasons. As this incident has shown, water entering and flooding the main-engine lube-oil system has serious consequences, as the rubber diaphragms are the only defence should the tank-top become flooded. Considering the potential risks associated with failure, rubber diaphragms could arguably be considered critical equipment.

- An examination of the Shiling’s maintenance system revealed that not only were the rubber diaphragms not considered critical, but they were not items required to be inspected or replaced because of their condition.

- The classification of critical equipment and systems has been inconsistent and problematic for the shipping industry for some time, partly owing to their definitions.

-

The IMO’s definition of critical equipment and systems is:

those where loss of functional capability or failure to respond when activated manually or automatically, may create a hazardous situation and/or cause an accident.

- The definition is all-encompassing, such that the failures of most equipment and systems will or can create hazardous situations. Consequently, when identifying critical equipment and systems, ship operators apply their own interpretations, and this creates variations within the sector.

-

There are many other definitions of critical systems, including the definition commonly used in the process of failure mode and effects analysis (FMEA):

those where loss of functional capability or failure to respond when activated manually or automatically, may cause a loss of control [of a ship].

-

Another definition, stemming from the oil and gas industry, is:

such parts of an installation and such of its plant (including computer programmes), or any part thereof, – the failure of which could cause or contribute substantially to, or the purpose of which is to prevent or limit, the effect of a major accident.

- The difference between these two definitions and the IMO definition is that their outcomes are more about preventing or managing serious consequences, whereas the outcome of the IMO’s definition is the prevention of a hazardous situation.

- The IMO’s exhaustive approach to identifying critical equipment has flow-on effects for ship operators’ risk- and safety-management systems. Operators are required to either carry or have quick access to spare parts on board for all critical equipment.

- Industry standards and guidance ought to be reasonable, be achievable and not incur costs that are grossly disproportionate to the benefits. The IMO’s definition of critical equipment and system is not in accord with that philosophy. The Commission is recommending that MNZ collaborate with other states to recommend the IMO review its definition.

Ship repair and maintenance records

Safety issue 2: When a ship changes ownership or management, there is no requirement for records of the inspection, maintenance or replacement of critical equipment and systems to be transferred with the ship. The absence of maintenance or replacement information on critical equipment and systems increases the likelihood of an accident as a result of their failure.

- The rubber diaphragms were not included in the planned-maintenance system for the Shiling, and other components (such as the rubber expansion couplings in the pipework for the centralised cooling system) were omitted from the list of critical components. The failure of a rubber expansion coupling recently caused the loss of control of a passenger- and freight-ferry in New Zealand, which had a centralised cooling system similar to that of the Shiling (Transport Accident Investigation Commission, May 2023).

- The IMO currently requires the maintenance of a ship’s continuous-synopsis record for security purposes under the International Ship and Port Facility Code. Similarly, the Commission has found that records of the repair and maintenance of critical equipment and systems should remain on board throughout a vessel's life for the purposes of safety.

- Currently, the only requirement for repair and maintenance records to follow a ship when its ownership or management changes is for any conditions of class to remain applicable to the ship if the classification society changes. Classification societies mainly focus on the survey of the hull and machinery, which only includes class surveyable items and does not include all critical equipment and systems.

- Depending on the contract of sale, when a ship is sold its historical maintenance records are not always passed on to the new ship operator. The operator must start a maintenance record anew, usually with only the running hours of the prime machinery as the baseline. This can lead to latent flaws in critical equipment and systems remaining undetected until failures occur. The failure of critical equipment can result in accidents with serious consequences.

- For the Shiling, there were many examples of flaws in critical equipment and systems that raise questions as to its seaworthiness (discussed further in paragraph 3.57).

- The failure of the rubber diaphragms used on the Shiling’s main engine was an industry-known issue that had led to catastrophic machinery failures on ships globally.

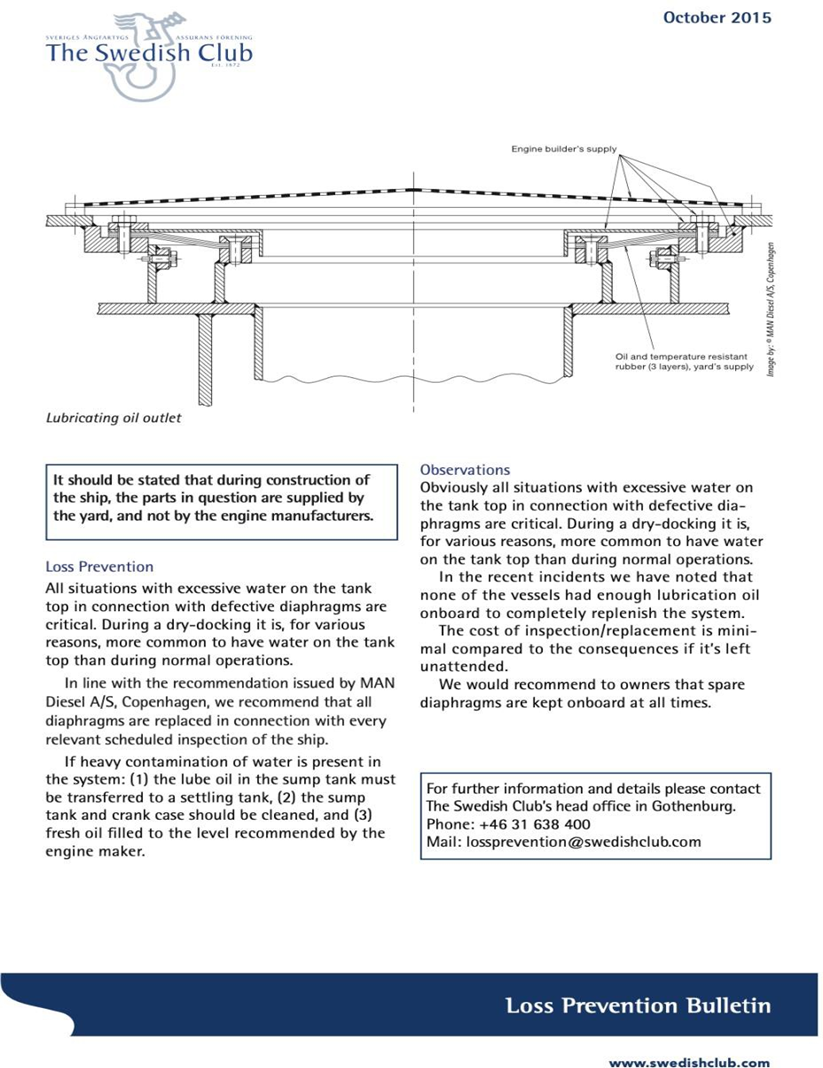

- The issue was first raised through a ‘Member Alert’ bulletin titled The “forgotten” rubber membrane, sent to ship owners and ship managers by the Swedish Protection and Indemnity [insurance] Club in 2007. The engine manufacturer published a service letter repeating the warning in 2008 (MAN Diesel A/S Denmark, March 2008). Following further failures of rubber diaphragms, the Swedish Club issued another bulletin in 2015 (The Swedish Club, October 2015) (see Appendix 2). The bulletins have been disseminated through industry by several classification societies and surveying companies.

- The bulletins advise that as rubber diaphragms are supplied by ship-building yards and not engine manufacturers, they are not listed as ‘engine parts’. Because of the variability in quality of the rubber diaphragms, ship owners and managers are advised to inspect and replace the rubber diaphragms:

- at the earliest opportunity after taking delivery of a new ship

- after every 32,000 running hours for the main engine

- every time the engine crankcase is opened for inspection (usually aligned with a drydock and/or a 32,000-hour inspection)

- at the earliest opportunity when taking delivery of an existing ship.

- The maintenance records for the Shiling were not passed on to Asian-Alliance when the Shiling was purchased in 2020. Asian-Alliance established a repair and maintenance system for the Shiling based on the running hours of the prime machinery and any manufacturers’ recommendations.

- On 24 February 2021, the Shiling’s engine manufacturer (then Wärtsilä) issued a further technical bulletin on the same topic, recommending that the rubber diaphragms be inspected every 6000 engine running hours and be replaced every 30,000 running hours.

- Asian-Alliance said that it had not received any of the previous bulletins on the rubber diaphragms or the 2021 technical bulletin and had not been aware of how critical they were to the safe running of the ship. Consequently, the rubber diaphragms were not inspected or replaced in 2020 when the ship was in drydock shortly after it had been purchased. The Lloyd’s survey records from the 2020 drydock reference inspections of several internal components of the main engine but recorded the inspection of the lube-oil sump as having been ‘waived’. No explanation for this waiver was available.

- It is very likely that the rubber diaphragms had not been inspected before the incidents in 2023; this is supported by the results of the testing by Quest Integrity (see Appendix 3). If the ship’s historical maintenance records had stayed with it when it changed ownership, the new operator would have likely been aware of the condition of the rubber diaphragms in the Shiling and other safety-critical equipment and systems, as long as the previous owner had classified these items as critical equipment.

- This case of ‘forgotten parts’ is a prime example of the importance of ensuring that the maintenance and inspection status of critical equipment stays with a ship through successive changes of ship owners and/or managers.

-

Concerns about maintaining a continuous record of maintenance have previously been raised at IMO by the United Kingdom and the Transportation Safety Board of Canada (TSB). The TSB has recommended that Canada’s regulator take the issue to the IMO, as outlined in the following TSB recommendation issued on 23 April 2009 (Transportation Safety Board of Canada, 2009):

Historical maintenance records and failure information on safety-critical equipment – including the steering, power, propulsion, lifesaving appliances, and damage control – are crucial to a ship’s manager and crew when assessing system performance and planning risk-based preventive maintenance. In this occurrence, following a recent change in the vessel’s management, previous managers retained historical records of failures and maintenance. As a result, adequate records and information on previous failures of and repairs to the steering gear were not readily available to the new manager and crew.

This is not the first instance where the TSB has identified the lack of continuous maintenance records as a safety issue. The investigation into an occurrence involving the Millenium Yama in 2000 revealed that the vessel had changed management five times. At the time of the occurrence, no reference documentation was found on board that would have allowed engine-room personnel to determine the condition and origin of a failed connecting rod.

Such a situation left a new manager without adequate information to make informed maintenance decisions and to ensure continued safety.

Canada is not alone in identifying discontinuity of maintenance records as an issue. Following a 2002 occurrence involving a lifeboat accident immediately after a change of vessel management, the United Kingdom’s Marine Accident Investigation Branch noted that all the vessel’s records other than the ship’s plans had been removed from the vessel. The issue was introduced at the IMO by the United Kingdom in 2004; however, to date, there has been little progress.

Given these safety deficiencies and their recognition by other flag states, the Board is concerned that the IMO has not addressed the risks associated with the non-retention of proper maintenance and failure records. Therefore, the Board recommends that:

The Department of Transport advocate at the International Maritime Organization (IMO) effective measures to ensure that maintenance and failure records remain on board throughout a vessel’s life.

- In July 2010, Transport Canada submitted a proposed amendment to the ISM Code that would require the retention of maintenance records upon changes of ownership. The proposal was met with support from some member nations, and Canada was invited to submit the proposal to the IMO Maritime Safety Committee for consideration as a new work item.

- In May 2012, at the IMO Maritime Safety Committee meeting, Transport Canada, in a joint submission with the Republic of South Korea, proposed amending the ISM Code to include a requirement for the transfer of a ship’s maintenance and failure records for safety-critical equipment with the sale of the ship. The Committee agreed to forward the proposal to the International Convention on Standards of Training, Certification and Watchkeeping for Seafarers’ Sub-Committee for consideration under ‘Enhancing the efficiency and user friendliness of the ISM Code’. However, the proposal was not adopted.

- Now, in 2025, the issue remains unresolved and is arguably more pressing with the decline in traditional ship owners that design, build, operate, maintain and recycle ships on a ‘cradle to grave’ model, concurrent with an increase in ‘middlemen’ ship owners who purchase ships for supply to large organisations on long-term contracts (Danish Ship Financing and Rainmaking Innovation, 2024; Maritimedata.ai, 2022).

- The Commission is recommending that MNZ collaborate with other states to raise the issue of continuity of maintenance records through the IMO, with a view to achieving the same outcome that Canada and the United Kingdom have attempted in the past, which is to make it mandatory for maintenance and repair records for critical equipment and systems remain on board throughout a ship’s life.

The ISM Code

Safety issue 3: The implementation of the ISM Code and the underlying safety-management system for the Shiling did not provide the assurance intended that the ship was maintained in accordance with minimum standards.

Safety issue 4: The ISM Code allows the owner of a ship to delegate all responsibility for managing the risks associated with the ship’s operation to a ship management company. The ship owner who creates the risk by placing the ship in service, and benefits from doing so, has no obligation to manage, or responsibility for managing, those risks or for ensuring that the operator is managing those risks in accordance with international and domestic legislation.

Safety Issue 5: The level of flag state Singapore oversight of the Shiling operations did not ensure the ship was seaworthy in all respects, even after regulatory scrutiny following the blackout event.

-

Under the ISM Code, a company’s (the owner of the ship or any other organisation or person, such as the manager or the bareboat charterer, who has assumed the responsibility for the operation of the ship from the ship owner) safety-management system was required to:

- provide for safe practices in ship operations and a safe working environment

- assess all identified risks to its ships, personnel and the environment and establish appropriate safeguards

- continuously improve the safety management skills of personnel ashore and aboard its ships.

- The company and ship safety-management system should ensure compliance with mandatory rules and regulations, and with the applicable codes, guidelines and standards recommended by the IMO, administrations, classification societies and maritime industry organisations.

-

Paragraph 10.1 of the ISM Code states:

The company should establish procedures to ensure that the ship is maintained in conformity with the provisions of the relevant rules and regulations and with any additional requirements which may be established by the company.

-

The ISM Code further states:

The procedures should be documented, and should ensure that applicable statutory, class [and] international [requirements] (for example the International Convention for the Safety of Life at Sea [SOLAS] and the International Convention for the Prevention of Pollution from Ships [MARPOL)] and port state requirements are met, and that compliance is maintained in the intervals between third-party surveys and audits.

-

The ISM Code further states:

The maintenance procedures should also include any additional requirements established by the company. These may arise, for example, from an analysis of the maintenance histories of machinery and equipment, from the particular demands of a ship’s operations, or from a manufacturer’s recommendations.

- Asian-Alliance held a valid ISM Code Document of Compliance issued by the flag state Singapore, and the Shiling held a valid ISM Code Safety Management Certificate, also issued by the flag state Singapore.

- Both Asian-Alliance and the Shiling were subject to regular audits of their respective ISM systems, conducted by organisations recognised by Singapore.

-

Despite holding the necessary documentation and certificates and having regular audits, the Shiling’s operation was not consistent in several respects with the objectives of the ISM Code. These included the:

1. substandard overall performance of the generator plant

2. substandard unattended engine-room alarm system, to the point where the crew could not operate the engine room unattended

3. classification society not being informed of the issues with the UMS, as the operator was required to do, and still holding a valid UMS class notation

4. planned-maintenance system for the ship, which included many outstanding and deferred items, many involving critical components and systems

5. number of deficiencies the Shiling was issued during successive PSC inspections in several countries (including New Zealand) before these two incidents. This had resulted in the Shiling being classified as a ‘high-risk’ ship under the PSC memorandums of understanding

6. number of deficiencies and conditions of class the vessel attracted after these two incidents

7. unknown deteriorated condition of the flexible rubber diaphragms that allowed water to enter the main-engine lube-oil tank

8. ship voyage data recorder not being fully functional

9. very limited protection on board against cyber-attack and control over cybersecurity.

- One of the PSC deficiencies issued by MNZ following the first incident related to a failure to meet the requirements of the ISM Code. Maritime New Zealand noted that the deficiencies it had identified were objective evidence that the safety-management system, as implemented on board, had failed to ensure the ship was managed in conformity with the Shiling’s safety-management system and with the relevant rules, regulations, codes and guidelines as required by the ISM Code.

- In addition, there were 559 overdue jobs in the ship’s planned-maintenance system, of which some were marked as critical or related to critical equipment. Maritime New Zealand noted that the flag state Singapore should undertake a full ISM audit.

- In response to the Shiling being detained after the first incident, MPA provided instructions to Lloyd’s, on behalf of the flag state, to carry out an ISM renewal audit.

-

The renewal audit resulted in four non-conformities being identified:

1. not all accidents and incidents that had occurred or defects that had been discovered on board had been reported, as required by SOLAS.

2. not all non-conformities raised with and reported to the company had been followed up to ensure that effective corrective actions and measures had been taken to prevent a reoccurrence. These had included deficiencies raised by the flag state Singapore in June 2022 that still had not been rectified. It also referred to the repair of a leaking main-engine fuel-injector control unit (that had caused the main-engine failure in July 2022 under pilotage at Wellington), without this repair being replicated for two other fuel-injector control units that were also found to be leaking.

3. planned maintenance for equipment, including critical equipment, had not been carried out at the appropriate intervals. It included the overdue maintenance of two of the four auxiliary generators and the non-verification of planned-maintenance tasks dating back as far as 2020 when Asian-Alliance first took over the management of the Shiling.

4. irregularities in the procedure for entering enclosed spaces on seven occasions.

- Following the Shiling’s departure from New Zealand on 7 July 2023 and subsequent drydock in Asia, the MPA conducted a flag state inspection on 12 September 2023. This inspection identified nine additional deficiencies, all unrelated to the incidents and conditions noted during the ship’s stays in Wellington. As a result, the MPA instructed Lloyd’s to conduct a further ‘extended scope survey’ on behalf of the flag state.

- The number of PSC deficiencies issued by MNZ against the Shiling and the number of deficiencies identified during the investigations into these two incidents suggests that the level of flag state regulatory oversight of the Shiling before these incidents did not ensure the ship was seaworthy in all respects.

- The relationship between ship owner, ship charterer (including sub-charterers) and ship operator is becoming more complex. Today ships change ownership and/or classification society and/or flag frequently.

- The Shiling was one such case. The current owner had purchased the Shiling, together with three other ships sourced by Asian-Alliance. The new owner had contracted the responsibility for operating the Shiling to Asian-Alliance on 1 February 2020, and the ship’s class and flag had also been changed.

- As established more than 50 years ago in the Robens report (Committee on Safety and Health at Work, 1972), risks lie with “those who create the risks and those who work with them”. The creator of the risks should identify the risks that they are generating and manage them effectively.

-

The ISM Code defines a ‘company’ as:

the owner of the ship, or any other organization or person such as the manager, or the bareboat charterer, who has assumed the responsibility for operation of the ship from the shipowner and who on assuming such responsibility has agreed to take over all the duties and responsibility imposed by the [ISM] Code.

- Beneficial ship owners and/or disponent ship owners are unlikely to have direct ‘hands-on’ responsibility for the day-to-day operation of their vessels, instead appointing ship-management companies to maintain and/or crew the vessels.

- The ISM Code is designed to ensure that ships operate according to good industry practice. However, the ISM Code has proven to be not as effective in ensuring safe ship operations as was envisaged when it was introduced through the IMO.

- The failure of an operator’s ISM system and those of the ships it operates is an all-too-common feature of accident reports and PSC deficiencies, even though in most cases the ships hold current valid ISM and survey certificates. Such was the case with the Shiling. This is described in more detail in the following section.

- One measure that could prove effective in raising compliance is to hold ship owners more to account for the safe operation of their ships. That is, hold them responsible for ensuring their operating companies are properly managing their ships in accordance with the IMO and state domestic shipping standards. The Commission is recommending that MNZ collaborate with other states to submit joint papers to the IMO (through the appropriate sub-committee) to change the ISM Code to achieve this.

Port and flag state control

Safety issue 6: PSC activity in New Zealand is not yet at a level to deter poorly maintained and/or managed vessels such as the Shiling from trading to New Zealand. This increases the risk of incidents and accidents occurring in and around the New Zealand coast.

- The IMO conventions and the United Nations Convention on the Law of the Sea (UNCLOS) state the responsibilities and rights of intervention expected from the flag states and port states to ensure that ships meet international standards.

-

The prime responsibility for ensuring a ship meets the required standards rests with the relevant flag state. However, a port state may intervene under certain circumstances if the standards are not being upheld and/or there is a risk to the immediate environment arising from the operation of the ship. These rights and responsibilities are explained in a study by the Secretariat of the IMO of the implications of UNCLOS for the IMO (Secretariat of the International Maritime Organization , 2014):

1. General

Port State Jurisdiction

By contrast to coastal State jurisdiction, the most important IMO conventions include provisions which regulate port State jurisdiction and the extent to which such jurisdiction should be exercised. It should be noted that, within the context of the implementation of IMO instruments, port State jurisdiction is a concept of an essentially corrective kind: it aims to correct non-compliance or ineffective flag State enforcement of IMO regulations by foreign ships voluntarily in port and is an incentive for flag State compliance.

The exercise of port State jurisdiction for the purpose of correcting deficiencies in the implementation of safety of navigation rules is established in the main IMO safety conventions, namely, Load Lines 1966, 1988 Load Lines Protocol, TONNAGE 1969, SOLAS 1974, SOLAS Protocol 1988, STCW 1978. These treaties regulate the right of the port State to verify the contents of certificates issued by the flag State attesting compliance with safety provisions. They also entitle the port State to inspect the ship if the certificates are not in order or if there are clear grounds to believe that the condition of the ship or of its equipment does not correspond substantially with the particulars of the certificates or if they are not properly maintained. SOLAS provides that the port State may check operational requirements when there are clear grounds for believing that the master or the crew is not familiar with essential shipboard procedure relating to the safety of the ship or procedures set out in the ship's safety-management system. …

2. Construction, Equipment and seaworthiness of Ships

General

Article 94(3)(a) of UNCLOS imposes upon flag States the obligation to ensure safety at sea on the high seas with regard to the construction, equipment and seaworthiness of ships. A further specification in relation to this obligation is provided in paragraph 4(a) of the same article, which indicates that measures to be taken by flag States must include those necessary to ensure "that each ship, before registration and thereafter at appropriate intervals, is surveyed by a qualified surveyor of ships, and has on board such charts, nautical publications and navigational equipment and instruments as are appropriate for the safe navigation of the ship". Paragraph 5 provides that in taking such measures "each State is required to conform to generally accepted international regulations, procedures and practices and to take any steps which may be necessary to secure their observance". This obligation also applies to the EEZ (article 58(2)). Article 217(2) of UNCLOS extends the scope of article 94(3) to the protection of the marine environment. It requires the flag State to ensure that its vessels are prohibited from sailing until they can proceed to sea in compliance with the requirements of international rules and standards with regard to design, construction and equipment of vessels. …

3. Port State Jurisdiction

General obligations

Article 219 of UNCLOS establishes that port States shall, as far as practicable, take administrative measures to prevent the sailing of a vessel which has been found to be in violation of applicable international rules and standards relating to seaworthiness of vessels and thereby threatens damage to the marine environment. The concept of seaworthiness should be understood not only as embracing provisions concerning the design, construction, manning, equipment and maintenance of vessels regulated in IMO instruments relating to maritime safety and security, but also those contained in MARPOL.

- The Shiling had had an active PSC record before being purchased by the current owner and before entering the New Zealand/Asia service.

- The Shiling had been in two previous incidents involving main-engine failures while under pilotage in New Zealand waters (both in Wellington).

- Maritime New Zealand had identified 16 deficiencies during the 3 PSC inspections in the year before these incidents, the most recent being about 1 month before the first incident.

- Substandard ships present real risks to not only the crew on board, but to the various entities involved with their operation while in New Zealand such as coastal and harbour pilots, stevedores and other contractors. They also present significant risks to the New Zealand environment if they are involved in an incident or accident involving the escape of oils or dangerous substances.

- Detaining ships under PSC is the tool currently available to MNZ to deter operators of substandard ships from trading them to New Zealand. Unlike Australia, MNZ does not have the ability to refuse a substandard ship entry to New Zealand territory. Australia has embarked on an intensive PSC campaign for many years, including exercising its power to refuse entry, with positive results that have deterred owners and operators of substandard ships from trading their ships to Australia.

-

Maritime New Zealand have advised the Commission that since 2022, PSC activity has been significantly enhanced in recognition of the importance of this activity and that they will continue to seek improvement. In particular, MNZ has taken the following active measures to deter substandard ships:

First, we have invested considerable time and resources in this area. This has involved setting up a Maritime Inspections Team, repurposing roles to fill this team, and seeking additional funding through a levy review. We were successful in this levy review and have now hired more people we are currently training, and it has also enabled us to increase resident PSC coverage in additional NZ ports.

…

Raised a paper at the Tokyo MOU highlighting the trend of loss of propulsion, and steering issues due to lack of maintenance that we are observing and encouraged other Administrations to take action against such kinds of ships (2023);

Published a Safety Bulletin on the risk of failure on Rubber Expansion Joints (REJs)(2023)

Proposed, developed, and delivered an in-person training seminar for PSCOs in the TMOU Region on enhanced machinery inspections, focussing on preventative maintenance (Feb 2024);

Drafted a safety bulletin which has been published on the Tokyo MOU website identifying a safety concern with emergency generators (2024);

Maritime NZ is also proposing to the Tokyo MOU to lead the development of guidelines for the inspection of engineering systems to improve PSCO inspections through TMoU guidelines (Nov 2024), and with success, potentially propose amendment to IMO resolution A.1185(33) – Procedures for Port State Control.

- The Director of Maritime New Zealand has no legal mechanism for preventing a ship trading to New Zealand based on repetitive poor survey performance. Under PSC, each inspection is exclusive in that it is not cumulative on previous inspections, except for deficiencies that have future dates assigned by which they must be rectified.

- In Australia, the Director of the Australian Maritime Safety Authority has the power to ‘ban’ a ship from trading to Australia based on serious, repetitive poor surveys or PSC performance. Banning a ship from trading to a country can have serious consequences for the ship owner, particularly if it is operating on long-term charter or on a liner trade to the country from which it has been banned.

- Having an intensive PSC presence and the potential for a ship to be banned would likely reduce the risks created by substandard ships operating into New Zealand. The Commission is recommending that the Ministry of Transport consider legislating to give MNZ the ability to ban certain ships from New Zealand.

Salvage capability in New Zealand

Safety issue 7: New Zealand does not have a sufficient and readily available tow salvage capability to adequately manage the foreseeable risk of a ship that has become disabled escalating to a marine casualty with consequential fatalities or serious harm and/or serious harm to the environment.

- The Shiling had little or no opportunity to re-establish propulsion after the main-engine lube oil became contaminated.

- Two factors favoured a recovery of the Shiling before it became a serious casualty: the weather conditions abated; and there was by chance a vessel nearby in New Plymouth that was suitable to tow the Shiling.

- However, the presence of suitable tow vessels in New Zealand is by no means guaranteed. Their presence is governed by other industries, predominantly the oil and gas industries off Taranaki, which have declined in recent years. It was fortuitous that on this occasion the Skandi Emerald was available to assist.

- Several recent incidents have highlighted the dangers of poor vessel maintenance. While no level of maintenance can eliminate the possibility of mechanical failure, inadequate upkeep significantly increases the risk. These incidents had serious and potentially catastrophic consequences.

- The Commission has made a recommendation to MNZ to work with the Ministry of Transport to strengthen New Zealand’s long-term maritime salvage and rescue capability.

Findings Ngā kitenga

- In the first incident on 15 April 2023, the Shiling suffered a blackout and consequential propulsion failure under pilotage in Wellington Harbour when exhaust gases from a cracked cylinder liner in generator 2 entered the centralised cooling system. This caused the three on-line generators to shut down or disconnect because of high cooling-water temperature.

- At the time of the blackout, the Shiling could not have been considered seaworthy for the voyage because its generator plant had not been maintained to an acceptable standard. This had increased the risk of blacking out with a consequential loss of control.

- The bridge team’s response to the loss-of-control situation was professional and well-coordinated, and it is virtually certain that the team prevented the ship grounding near the Wellington Harbour entrance channel.

- In the second incident on 12 May 2023, the Shiling suffered a main-engine failure off Farewell Spit, owing to water contamination of the main-engine lubricating-oil system. Water had accumulated on the engine-room tank-top and entered the lube-oil tank via failed rubber diaphragms that linked the main-engine sump with the reservoir.

- The engine manufacturer recommended inspecting and/or replacing the rubber diaphragms during major surveys and drydocks. For the Shiling, records showed that they were not inspected when the ship drydocked in 2020 after changing vessel ownership, ship management, classification society and flag state.

- It was not possible to trace the inspection and replacement history for the failed rubber diaphragms because of the lack of a continuous maintenance record between successive ship owners and managers.

- A requirement that records of the repair and maintenance of critical equipment and systems be retained with a ship when ownership and/or management changes would reduce the risk of incidents and accidents from failures of safety-critical systems.

- The IMO definition of critical equipment and systems is so broad that it provides no meaningful direction as to what ship owners and managers should consider as critical, both when setting up their repair and maintenance systems and when identifying the repair and maintenance records that should be retained on board when ownership or management of the ship change.

- The Commission’s investigation, and the post-incident inspections and surveys conducted by MNZ and the attending class surveyors, identified numerous deficiencies in repair and maintenance on board the Shiling. These deficiencies indicated that the safety-management systems for the ship and the ship management company were not effective in ensuring compliance with the various international and domestic standards, codes and guidelines.

- There was sufficient justification after the first incident for the flag state, Singapore, to have imposed regulatory interventions, requiring immediate improvements in the repair and maintenance actions on board Shiling, and longer-term improvements in the effectiveness of the ship’s and the ship operator’s respective safety-management systems.

- The fortuitous availability of a suitable tow vessel in the area where the Shiling became disabled facilitated the salvage of the ship to a safe port. The threat to life and the New Zealand coastal environment posed by ships becoming disabled will remain unacceptably high until New Zealand takes some measures to improve its tow salvage capabilities.

Safety issues and remedial action Ngā take haumaru me ngā mahi whakatika

General

- Safety issues are an output from the Commission’s analysis. They may not always relate to factors directly contributing to the accident or incident. They typically describe a system problem that has the potential to adversely affect future transport safety.

- Safety issues may be addressed by safety actions taken by a participant; otherwise the Commission may issue recommendations to address the issues.

Safety issue 1: The International Maritime Organization’s definition of critical equipment and systems (a lack of which may create hazardous situations and/or cause accidents) is so broad that it is ineffective in defining what is critical and what is not.

- No action has been taken to address this safety issue. Therefore, the Commission has made a recommendation in Section 6 to address the issue.

Safety issue 2: When a ship changes ownership or management, there is no requirement for records of the inspection, maintenance or replacement of critical equipment and systems to be transferred with the ship. The absence of maintenance or replacement information on critical equipment and systems increases the likelihood of an accident as a result of their failure.

- No action has been taken to address this safety issue. Therefore, the Commission has made a recommendation in Section 6 to address the issue.